What is Thorp?

The Thermal Oxide Reprocessing Plant on the Sellafield site in West Cumbria.

What is Thorp?

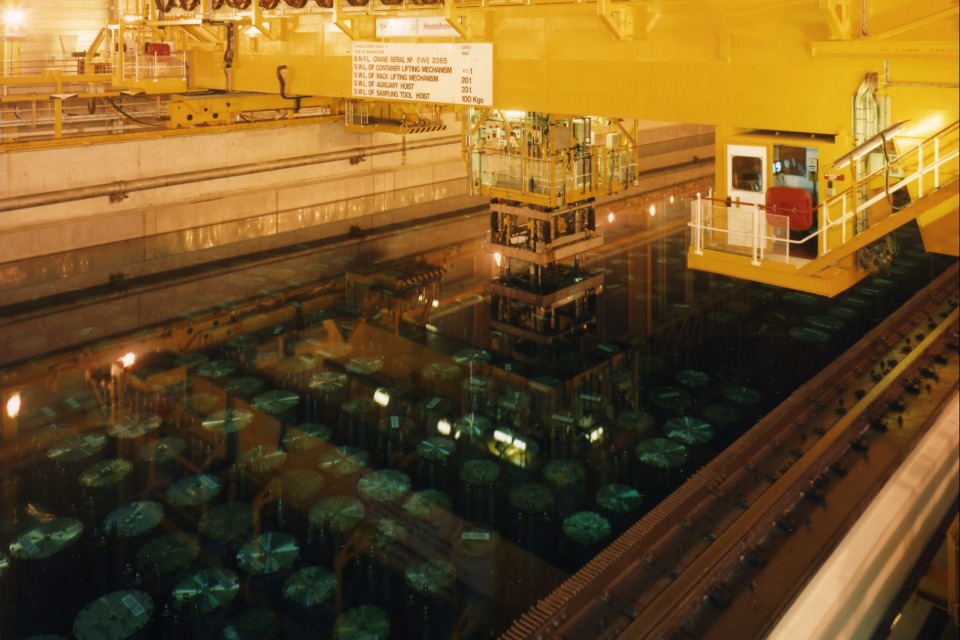

Today, the ponds inside the Thermal Oxide Reprocessing Plant (or as we like to call it, Thorp) are used to store nuclear fuel that has been used in the UK’s 7 operational nuclear reactors.

Before taking on this new mission, Thorp reprocessed 9,000 tonnes of used nuclear fuel from around the world, generating an estimated £9 billion in revenue for the UK over 2 decades.

The parts of the plant that were used to reprocess used fuel are called ‘chemical separation’ and are currently going through a process called Post Operational Clean Out (POCO).

A pulse column used in the chemical separation process

This stage sees our teams removing any remaining radioactive and non-radioactive materials from the plant and is the first stage of decommissioning.

In this case study we’ll share:

- How we’re helping to keep the UK’s lights on by safely looking after used nuclear fuel.

- The history of one of the biggest nuclear buildings on the Sellafield site.

Thorp is helping to keep the UK’s lights on

Even though it’s original reprocessing mission came to an end in 2018, Thorp continues to key role in the UK’s energy strategy.

Ponds inside the plant that were originally used to store spent oxide fuel before it was reprocessed have been modified so that they can store Advanced Gas-cooled Reactor (AGR) fuel.

By doing this Thorp:

Supports electricity generation in the UK

With limited interim storage at the AGR reactor sites, spent fuel is transferred to the Sellafield site. This is crucial in enabling continued nuclear reactor operation and electricity generation within the UK.

Supports with the bulk-defueling of AGR reactors

As the fleet of 7 UK AGR power stations start come to the end of their operational life, Thorp is also playing a key role in assisting with the bulk defueling (similar to refuelling a reactor but new fuel isn’t put back in) of the reactors before they are decommissioned.

As of September 2024, 3 of the reactors (Hunterston B, Hinkley Point B and Dungeness B) have ceased generating and begun defueling.

All other reactors are expected to have completed their defueling operations by the early 2030s.

At this point there will no longer be new commercial nuclear fuel being received into the ponds.

Making changes to Thorp’s receipt and storage ponds

Our teams have been working to make some changes and improvements to Thorp’s receipt and storage pond so that used nuclear fuel can be stored safely for longer.

The receipt and storage area in Thorp

Storage

The Thorp receipt and storage ponds hold the same volume of water as 20 Olympic sized swimming pools. Although large, its storage capacity is finite.

The solution has been the development and deployment of a new design of fuel can storage racks. Because these new racks are taller but have a smaller footprint than the previous design, they can hold 6,000 tonnes of fuel each. That’s more than 50% more fuel than the previous design.

Fuel that was already being stored in the pond is being transferred into the new storage racks and all future fuel receipts will be stored in this way.

Thorp’s history

Thorp’s story started back in the mid-1970s when a new fleet of nuclear reactors came online and used oxide fuels rather than Magnox fuel. Thorp was designed to reprocess this fuel after it had been used inside the reactors.

Planning and construction of Thorp (1974 to 1988)

1974 to 1978

- For 100 days in 1977, a public inquiry - The Windscale Inquiry - looked at the implications of building Thorp.

1978

- The government approved the construction of Thorp.

- This new building at Sellafield would stretch over a third of mile, housing the facilities needed to reprocess oxide fuel under one roof.

1981

- Site clearance and construction began. Thorp was one of the largest and most complex construction projects in Europe, rivalled only by the Channel Tunnel and Disneyland Paris.

1984

- Major civil work began.

- The construction project dominated the site, and the local area. Local towns and villages were filled with the thousands of construction workers required to make this one-stop shop a reality.

- It was one of the biggest construction projects of its times and saw more than 5,000 people on site and a further 10,000 roles in the supply chain.

1988

- The receipt and storage pond opened, taking receipt of the first batch of irradiated fuel.

- The pond is the size of 20 Olympic swimming pools, at 73m long, 23m wide and 8m deep.

1993

- Following a further major Government review of the viability of the project, Thorp was given permission to operate.

Thorp operations (1994 to 2018)

1994

- Thorp reprocessing facility becomes operational with the first batch of fuel sheared.

- Shearing is where nuclear fuel is cut into pieces at the beginning of the reprocessing cycle.

1997

- Thorp is fully operational and has 34 customers in nine different countries.

2005

- The plant temporarily closed due to pipe failure in the feed clarification cell.

2011

- The Nuclear Decommissioning Authority started to consider the credible options for the future of Thorp, looking at safety, cost, technical and performance risks.

2012

- 7,000 tonnes of fuel have now been reprocessed.

- The decision is made to close Thorp in 2018 when existing contracts have been completed.

2018

- The last batch of fuel to be reprocessed began its journey through the plant at 11.32am on Friday 9 November.

- Over its lifetime, Thorp reprocessed 9,000 tonnes of fuel from around the world, generating an estimated £9 billion in revenue for the UK during its lifetime.

Further reading and sources

New era at Sellafield as Thorp reprocessing ends

End in sight for reprocessing nuclear fuel at Sellafield

The Sellafield Magazine - issue 8

The Sellafield Magazine - issue 6

Overview of the Production and Management of Radioactive Waste in the UK - fact sheet (nda.gov.uk)