Raising product standards for space heating: updating ecodesign and energy labelling for hydronic space and combination heaters (HTML)

Published 17 December 2024

Executive summary

Introduction

Improving heating appliance efficiency can deliver significant consumer bills savings – by reducing energy consumption – also leading to reduced carbon emissions and increasing energy security by reducing dependence on volatile fossil fuel energy markets.

This consultation sets out proposals which will drive significant improvements in the efficiency of new heating appliances and deliver substantial bill savings for households purchasing gas boilers and heat pumps. The new energy efficiency proposals for gas boilers are expected to deliver average savings of over £30 per year, equating to a £450 saving over the 15-year life of the boilers, once the full set of changes are implemented from 2028. In advance of this, the first tranche of proposals expect to see gas boiler households benefit in a £19 yearly saving. These savings quickly offset the increased capital costs of approximately £50.

Heat pump running costs can be similar or higher than gas boilers, despite being three times more efficient, because they use electricity rather than gas. To assist with heat pump running costs, this consultation sets out new heat pump efficiency proposals which expect to deliver a bill saving for households of around £22 per year from 2029. These savings are expected to quickly offset the estimated increased capital costs of £56.

To realise these benefits, we are proposing to update ecodesign and energy labelling regulations for space and combination heaters. Ecodesign legislation has historically been an effective way of reducing energy consumption by driving higher performance of energy-related products.[footnote 1] It has achieved this by preventing less efficient products from being placed on the market through new minimum requirements, driving innovation by setting benchmarks for the highest standard of products and introducing a compliance regime delivered through market surveillance authorities. Accompanying energy labelling legislation has also improved the clarity and consistency of consumer information, supporting effective choice and competition.

This consultation sets out our proposals to go beyond the present requirements of ecodesign legislation (813/2013) and energy labelling legislation (811/2013) to further drive the efficiency of space heating products.[footnote 2] These proposals build on the research and evidence gathered through the Improving Boiler Standards and Efficiency consultation[footnote 3], Boiler Plus Standards review[footnote 4], and Energy-related products: call for evidence[footnote 5]. The draft statutory instrument (SI), which is based on the proposals in this document, will be published alongside this consultation in due course, at which point the consultation period will begin. The SI is referenced throughout.

Hydrogen-ready boiler standards will not be considered through this update to ecodesign and energy labelling. The government has recently announced its intention to assess the current evidence base before consulting in 2025 on the role of hydrogen in home heating. The government will consider whether any changes to the approach to hydrogen-ready boilers is warranted following that consultation process.

We are aware that since 2018 the European Commission has been reviewing and planning to update the EU’s ecodesign and energy labelling legislation for hydronic space heaters.[footnote 6] We have carefully considered this work in our policy formulation and the drafting of the statutory instrument (SI). Despite the ongoing uncertainty regarding the final form of the EU’s legislation, we will continue to give this work close attention as it evolves.

The Office for Product Safety and Standards (OPSS), within the Department for Business and Trade, is the appointed Market Surveillance Authority for ecodesign and energy labelling regulations in Great Britain and will provide oversight for implemented proposals.

Proposals

In this consultation we are seeking views on proposals to improve product standards by updating ecodesign and energy labelling legislation for space and combination heaters to reduce energy bills, decarbonise heating and improve energy security by:

- enabling electrification of heat (Part 1)

- reducing fossil fuel demand (Part 2)

- ensuring effectiveness of product standards (Part 3)

- improving energy labels (Part 4)

Enabling electrification of heat proposals are part of a wider package of policies which aim to scale up heat pump deployment and support industry to reduce the upfront and ongoing costs of heat pumps. The proposals outlined here include: amending the primary energy factor for electricity (Chapter 1), updating definitions and minimum energy performance standards for low-, medium-, and high-temperature heat pumps and hybrid heaters and updating the testing methodology required (Chapters 2 and 4), and exploring how to make sure hot water cylinders are compatible with low-temperature systems, including heat pumps (Chapter 3).

Reducing fossil fuel demand from the estimated 10 million plus boiler installations anticipated over the next decade can help to save consumers money on their bills, cut carbon emissions and increase energy security by reducing dependence on volatile fossil fuel energy markets. The fossil fuel boiler proposals include implementing minimum modulation requirements for gas combination boilers and establishing a default flow temperature factory setting (Chapter 5). The temperature control proposals include: transferring temperature control classes into the regulations and preventing Control Classes I-III from being placed on the market in Great Britain (GB), setting requirements to use open protocols, and requiring temperature controls to be accompanied by information about which open protocols they can use (Chapter 6).

Ensuring effectiveness while ensuring any product cost increases are limited and businesses remain competitive is essential to maximise the benefits of ecodesign legislation. Proposals include: updating performance benchmarks (Chapter 7), allowing boiler manufacturers to self-certify their products, narrowing verification tolerances, and reducing circumvention (Chapter 8), and seeking views whether to expand the scope of ecodesign (Chapter 9).

Improving energy labels can help users and installers make informed decisions about what to buy. Proposals include rescaling the space heating energy efficiency classes (Chapter 10) and updating designs for energy labels and visual advertising pictograms (Chapter 11).

The United Kingdom (UK) is committed to net zero greenhouse gas emissions by 2050. This will require significant transformation to decarbonise heating, which accounted for 22% of the UK’s carbon emissions in 2022.[footnote 7] Our analysis estimates that these policies will also contribute to the equivalent carbon savings of 2.0 million tonnes (MtCO2e) for Carbon Budget 5 (which covers 2028 – 2032), and up to 3.8 MtCO2e for Carbon Budget 6 (which covers 2033 – 2037).

We welcome views and evidence on the proposals set out in this document and on the accompanying draft SI. We aim to publish a government response and accompanying regulations shortly after the closure of this consultation, in 2025. The earliest the proposals could be implemented is 2026. However, this is subject to the decisions following this consultation and when parliamentary time allows.

A glossary of terms can be found in Annex A. The full list of the questions asked in this consultation is included in Annex B. A full bibliography is provided in Annex C.

General information

Why we are consulting

Improving product standards can save consumers money by reducing their bills, while cutting carbon emissions and increasing energy security. Product regulations, such as those set out in ecodesign and energy labelling legislation, are, therefore, a key lever to help reduce greenhouse gas emissions to net zero by 2050.

We have identified a variety of opportunities to update product standards for space and combination heaters which aim to enable electrification of heat, reduce fossil fuel demand, ensure effectiveness and improve energy labels.

We welcome views and evidence on the proposals set out in this document and on the accompanying draft SI.

Consultation details

Issued:17 December 2024

Respond by: 25 March 2025 11:59pm

Enquiries to:

Energy-related Products team, the Department for Energy Security and Net Zero

Consultation reference: Raising product standards for space heating

Audiences: We are seeking views from all – including manufacturers, merchants and dealers, installers, associations, consumer organisations, academia and members of the public – to ensure that we understand all potential impacts of our proposals.

Territorial extent: The proposed updates to ecodesign and energy labelling set out in this consultation would apply to GB. To facilitate dual access to both the UK Internal Market and the EU Single Market, Northern Ireland continues to apply EU ecodesign and energy labelling regulations in accordance with the Windsor Framework. As the UK government is looking to introduce higher requirements in GB than the current standards applicable in Northern Ireland, goods compliant with these higher requirements will also be able to be placed on the market in Northern Ireland. At the same time, Northern Ireland businesses will continue to have unfettered access to the GB market. Accordingly, the proposals set out in this consultation will not inhibit trade between Great Britain and Northern Ireland.

How to respond

We strongly encourage responses via the online survey. Using the online survey greatly assists our analysis of the responses, enabling more efficient and effective consideration of the issues raised. If it is not possible for you to use the online survey, you can respond through email or a written response.

Email to:

spaceheatingstandards@energysecurity.gov.uk

Write to:

Energy-related Products

Department for Energy Security and Net Zero

3-8 Whitehall Place

London

SW1A 2EG

When responding, please state whether you are responding as an individual or representing the views of an organisation.

Your response will be most useful if it is framed in direct response to the questions posed, though further comments and evidence are also welcome.

Confidentiality and data protection

Information you provide in response to this consultation, including personal information, may be disclosed in accordance with UK legislation (the Freedom of Information Act 2000, the Data Protection Act 2018 and the Environmental Information Regulations 2004).

If you want the information that you provide to be treated as confidential, please tell us, but be aware that we cannot guarantee confidentiality in all circumstances. An automatic confidentiality disclaimer generated by your IT system will not be regarded by us as a confidentiality request.

We will process your personal data in accordance with all applicable data protection laws. See our privacy policy.

We will summarise all responses and publish this summary on GOV.UK. The summary will include a list of names or organisations that responded, but not people’s personal names, addresses or other contact details.

Quality assurance

This consultation has been carried out in accordance with the government’s consultation principles.

If you have any complaints about the way this consultation has been conducted, please email: bru@energysecurity.gov.uk.

Part 1: Enabling electrification of heat

To meet net zero, we need to move away from using fossil fuel systems to heat homes, such as gas boilers, towards low-carbon heating technologies. Heat pumps have a critical role to play in decarbonising how we heat our homes. The government is committed to supporting the growth of the heat pump market.

While a highly efficient and low-carbon alternative to existing fossil fuel systems, it is crucial that the heat pumps installed into homes deliver for consumers and keeps bills as low as possible. This requires pushing the market to ensure they are as efficient as possible. This has the added benefit of ensuring electricity demand is low. As set out above, the policies set out are expected to lead to a bill reduction of around £22 per year.

Because most of the heat output of a heat pump is drawn from the ground or outside air, heat pumps produce several units of heat for every unit of energy consumed, meaning replacing a boiler with a heat pump is often the most impactful measure for reducing a building’s energy demand. At the same time, the UK’s electricity generation mix is producing increasingly lower greenhouse gas emissions each year.

Government is committed to supporting the growth of the UK heat pump industry and is providing up to £30 million towards a Heat Pump Manufacturing Investment Accelerator Competition. A range of policies also exist to drive heat pump uptake, including the Boiler Upgrade Scheme[footnote 8], which provides grants to encourage property owners to replace existing fossil fuel heating with more efficient, low-carbon heating systems including air-source heat pumps and ground-source heat pumps.

Due to developments in heat pump technology, it is clear that heat pumps are capable of achieving much higher efficiencies than the minimum energy performance standards (MEPS) currently require.

Part 1 of this consultation sets out proposals to update ecodesign and energy labelling regulations for heat pumps. In addition, we propose to introduce new requirements for hybrid heat pumps, as well as amendments to ensure hot water cylinders are compatible with heat pumps and designed to work in a wet low-temperature heating system. In summary, the proposals included in Part 1 are to:

- amend the primary energy factor for electricity, used to calculate seasonal space heating energy efficiency for space heaters, to 1.9

- increase MEPS for low- and medium-temperature heat pumps, and introduce new energy performance standards for high-temperature heat pumps

- amend the definition of low-temperature heat pumps, and introduce new definitions for medium- and high-temperature heat pumps

- update the testing methodology required to establish the seasonal space heating energy efficiency of heat pumps and hybrid heat pumps, in line with EU law

- explore amendments to hot water cylinders to make them low-temperature systems / heat pump compatible

- create a new definition for hybrid heat pumps

- introduce MEPS for hybrid heat pumps

These policy proposals are part of a wider package of policies which aim to scale up heat pump deployment and support industry to reduce the upfront and ongoing costs of heat pumps.

Chapter 1: Primary energy factor

Introduction

Setting MEPS for energy-related products is an important policy lever to reduce energy demand and lower consumer bills.

To make MEPS comparable between products, ecodesign and energy labelling regulations use seasonal space heating energy efficiency to test performance (and compliance with MEPS). The seasonal space heating energy efficiency is calculated by adjusting the seasonal coefficient of performance (SCOP) to account for primary energy.

The conversion coefficient (CC) acts as a primary energy factor for electricity. The current CC (primary energy factor for electricity) in GB ecodesign (813/2013) is 2.5. This figure was retained when we left the EU and therefore represents an outdated EU value, introduced with the Energy Efficiency Directive in 2012. This CC is not reflective of electricity production in GB in 2024. Given the decarbonisation of the electricity grid over the last decade, we need to ensure that this is reflected in our broader policies. Updating the primary energy factor for electricity used in ecodesign is an important element of this and will help ensure the carbon benefits of using efficient electric space heating technologies, such as heat pumps, are properly recognised.

Context

Primary energy is energy that has not undergone any conversion or transformation process, for example oil or gas. Secondary energy is generated by converting or transforming this primary energy, for example electricity generated by burning fossil fuels.

The primary energy factor describes the efficiency of converting energy from primary sources (renewables such as wind, solar hydropower or fossil fuels such as coal or crude oil) to a secondary energy carrier (such as electricity or natural gas) that provides energy services delivered to end-users. The calculation is as follows:

Description of calculation: ‘Primary Energy Factor’ equals 1 plus the sum of ‘All process stages’ open parenthesis ‘Energy use’ over ‘Energy content of delivered fuel’ close parenthesis.

Less energy is lost when converting from renewables to electricity, than from burning fossil fuels to generate electricity. Therefore, as the electricity grid decarbonises, we can expect the primary energy factor for electricity to reduce.

The Home Energy Model for the Future Homes Standard (2023) proposed a primary energy factor for electricity of 1.969[footnote 9] for England and Wales. The government response to this consultation is expected in due course. However, the proposed figure is similar to the updated figure proposed by the European Commission in 2023. In 2023, the European Commission updated the primary energy factor in the Energy Efficiency Directive to a CC of 1.9[footnote 10], to better reflect the energy mix of electricity in the EU.

Having a different primary energy factor in EU and GB ecodesign regulations for space heaters could create difficulties for manufacturers, many of whom sell in both markets. They would have to calculate seasonal space heating energy efficiency for their products twice using two different primary energy factors. We wish to avoid creating unnecessary barriers and costs for industry which do not result in any real-world improvements to efficiency.

Updating primary energy factor to 1.9

To better reflect the GB electricity grid, to future-proof the value and to minimise unnecessary friction to trade, we propose lowering the CC, which represents the primary energy factor for electricity for GB, from 2.5 to 1.9. This change will be made to ecodesign (813/2013) as set out in regulation 19 of the draft SI. We propose to introduce this CC from mid-2026, in line with the earliest implementation date of other proposals in this consultation.

Chapters 2 and 4 describe proposals to increase MEPS for low- and medium-temperature heat pumps, and introduce MEPS for high-temperature heat pumps and hybrid heat pumps. These proposals are based on a conversion coefficient of 1.9.

Electric boilers

To continue to allow a comparison between products using different fuels, existing MEPS for products fuelled by electricity, which we are not proposing to increase in this consultation, must be updated to reflect the new primary energy factor. This does not represent an increase in the performance required of the product, but merely an adjustment to accommodate a new conversion coefficient that better represents the electricity that product uses.

Electric boiler space heaters and electric boiler combination heaters run purely using electricity. Therefore, the MEPS for electric boilers must be updated in line with the new primary energy factor.

Ecodesign requires electric boiler space heaters and electric boiler combination heaters to have a seasonal space heating energy efficiency of at least 36%, based on a primary energy factor of 2.5. We propose to update this figure to 47%, based on a primary energy factor of 1.9. This change will be made to ecodesign (813/2013).

Please review regulation 18(2) of the draft SI.

1. Do you agree with lowering the primary energy factor for electricity to 1.9 frommid-2026? Yes/No/Don’t know. Please provide evidence or reasoning to supportyour answer.

Chapter 2: Heat pumps

Introduction

Heat pumps have a critical role to play in decarbonising how we heat our homes, as they provide a highly efficient and low-carbon alternative to existing fossil fuel systems. A range of policy measures, such as the Boiler Upgrade Scheme in England and Wales, exist to encourage the installation of heat pumps in homes and help overcome the high upfront cost compared to fossil fuel alternatives.

This consultation sets out proposals to increase MEPS for low- and medium-temperature heat pumps, and introduce MEPS for high-temperature heat pumps.

Context

In 2020, stakeholder views were sought on increasing MEPS for heat pumps, via the Energy-related products: call for evidence. These fed-into the Energy-related Products Policy Framework[footnote 11], which set out illustrative proposals for new MEPS for heat pumps, and an intent to consult.

Following further research, analysis and modelling, and engagement with industry, these have been revised and the policy proposals set out below seek to ensure that only the most energy efficient products are available on the market, while also ensuring consumer choice is maintained.

Minimum Energy Performance Standards

As an established technology, heat pumps are subject to MEPS under ecodesign (813/2013). The metric used to set MEPS is the seasonal space heating energy efficiency (ƞs) which expresses energy efficiency in primary energy terms, i.e. the efficiency of the energy source is factored into the efficiency calculation. This allows for a comparison between different technologies using different energy sources. Chapter 1 sets out proposals to update the primary energy factor from 2.5 to 1.9. The MEPS proposals set out in this chapter are based on a primary energy factor of 1.9.

Currently MEPS requirements are placed on low and medium-temperature heat pumps via ecodesign (813/2013):

- low-temperature heat pumps are subject to MEPS of 125%, tested at 35°C and based on a primary energy factor of 2.5

- all other heat pumps heat pumps are subject to MEPS of 110%, tested at 55°C and based on a primary energy factor of 2.5

These MEPS are no longer pushing the market towards selling more efficient products. Products cluster near the current minimum requirements as it is cheaper to produce less efficient products. Market forces will drive products to the cheaper end, at a long-term cost to the consumer society from energy consumption. Therefore, government must intervene to increase the MEPS, to ensure consumers are not paying higher bills due to purchasing less efficient products than the market is capable of producing.

Following analysis and modelling of the Microgeneration Certification Scheme (MCS) database, as well as learnings from previous industry engagement, we are proposing the following heat pump MEPS, based on a primary energy factor of 1.9. We are proposing that these come into force in two tiers: tier 1 in mid-2027, and tier 2 in mid-2029. We are also keen for views on the feasibility of a faster implementation, with tier 1 in mid-2026 and tier 2 in mid-2028. We also propose to update heat pump definitions in line with the new MEPS categories proposed (as set out in the Terminology and testing section below):

- low-temperature heat pumps (tested at 35°C): 170% in mid-2027 and 175% in mid-2029 – this would be equivalent to heat pumps with SCOPs of 3.29 and 3.38, respectively

- medium-temperature heat pumps (tested at 55°C): 168% in mid-2027 and 175% in mid-2029 – this would be equivalent to heat pumps with SCOPs of 3.25 and 3.38, respectively

- high-temperature heat pumps (tested at 65°C): 143% in mid-2027 and 153% in mid-2029 – this would be equivalent to heat pumps with SCOPs of 2.77 and 2.96, respectively

We are proposing MEPS at these efficiency levels as we know that manufacturers can produce more efficient products; in most cases a manufacturer will be producing multiple products with different efficiencies in the same factory. These MEPS proposals have been selected to remove the least efficient ~40% of the market in the tier 1 changes. This approach has been shown to maximise energy savings, while also not leaving gaps in either the product types available on the market or leaving manufacturers unable to switch to a viable product. In most cases manufacturers are already producing compliant products, it is a matter of reprioritising production. We anticipate that the lead in time for implementation which we have proposed in the draft SI, in combination with our compliance with the 6-month standstill obligation under the WTO’s Technical Barriers to Trade Agreement, should allow manufacturers time to adjust their production. We are particularly interested in views from manufacturers about the lead-in time.

We are proposing to introduce a new, distinct MEPS for heat pumps operating at high-temperature (65°C). Although we estimate high-temperature heat pumps make up a small proportion of the current GB market (11%), we anticipate their growth will continue. We are interested in views from stakeholders about the feasibility of introducing MEPS for high-temperature heat pumps now, and whether the efficiencies proposed are appropriate.

For the consumer, the electricity savings from using more efficient products will outweigh the potential small upfront cost increase as a result of the new efficiency standards. Without raising MEPS, consumers are likely to buy products with lower efficiencies as they do not realise, or ignore, the opportunity cost of buying a less efficient product at lower upfront cost.

We are aware that the EU’s f-gas regulations[footnote 12], which will prevent the sale of heat pumps which use specific f-gases from 2027, may have an impact on the supply of heat pumps in the medium-term. We are keen to understand the interaction between these MEPS proposals and the EU’s f-gas regulations, and their own 2023 ecodesign (813/2013) proposals, and welcome discussion and evidence from consultation respondents on this topic.

This change will be made to ecodesign (813/2013). Please review regulation 18(2) of the draft SI.

2. Do you agree that we should raise the MEPS to 170% for low-temperature heat pumps under tier 1? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

3. Do you agree that the tier 1 increase in MEPS to 170% for low-temperature heat pumps should take effect from mid-2027? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

4. Do you agree that we should raise the MEPS to 175% for low-temperature heat pumps under tier 2? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

5. Do you agree that the tier 2 increase in MEPS to 175% for low-temperature heat pumps should take effect from mid-2029? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

6. Do you agree that we should raise the MEPS to 168% for medium-temperature heat pumps under tier 1? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

7. Do you agree that the tier 1 increase in MEPS to 168% for medium-temperature heat pumps should take effect from mid-2027? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

8. Do you agree that we should raise the MEPS to 175% for medium-temperature heat pumps? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

9. Do you agree that the tier 2 increase in MEPS to 175% for medium-temperature heat pumps should take effect from mid-2029? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

10. Do you agree that we should raise the MEPS to 143% for high-temperature heat pumps under tier 1? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

11. Do you agree that the tier 1 increase in MEPS to 143% for high-temperature heat pumps should take effect from mid-2027? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

12. Do you agree that we should raise the MEPS to 153% for high-temperature heat pumps under tier 2? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

13. Do you agree that this tier 2 increase in MEPS to 153% for high-temperature heat pumps should take effect from mid-2029? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

14. Do you have any views on whether the MEPS could be implemented at a faster rate, with tier 1 in mid-2026 and tier 2 in mid-2028? Please provide evidence or reasoning to support your answer.

15. Do you have any views on the interaction between the MEPS proposals for heat pumps and the EU’s f-gas regulations? Please provide evidence or reasoning to support your answer.

Where a heat pump can operate at more than one temperature application, we are proposing that the heat pump will be required to be tested at all relevant temperature applications and meet the corresponding MEPS at each temperature. Please see the section below on the proposed amended definitions of heat pumps and temperature application. We are keen to understand the impact this would have on high temperature heat pumps in particular.

16. What impacts would occur as a result of requiring heat pumps to meet the MEPS for all temperature applications they operate at? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

Terminology and testing

We are proposing to update the testing method to align with the European Commission’s latest proposals. This will enable the implementation of MEPS for high-temperature heat pumps, and bringing testing requirements in line with the Commission’s proposals should prevent manufacturers selling products in GB and EU from having to perform seasonal space heating energy efficiency tests twice, to two different standards. We propose designating the existing relevant standards, including BS EN 14825:2022[footnote 13].The draft SI accompanying this consultation has been updated in line with the Commission’s most recent proposals. Please review regulation 19 of the draft SI.

17. Do you agree that BS EN 14825:2022 and BS EN 14511-2-2022 are appropriate means of calculating the seasonal space heating energy efficiency for a heat pump, despite the fact that they are currently behind a paywall? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

We also propose updating the definitions for heat pump types and temperature applications, in line with the Commission’s latest proposals. The existing definitions as set out in ecodesign (813/2013) are:

- ‘low-temperature heat pump’ means a heat pump space heater that is specifically designed for low-temperature application, and that cannot deliver heating water with an outlet temperature of 52 °C at an inlet dry (wet) bulb temperature of – 7 °C (– 8 °C) in the reference design conditions for average climate

- ‘low-temperature application’ means an application where the heat pump space heater delivers its declared capacity for heating at an indoor heat exchanger outlet temperature of 35 °C

- ‘medium-temperature application’ means an application where the heat pump space heater or heat pump combination heater delivers its declared capacity for heating at an indoor heat exchanger outlet temperature of 55 °C

We propose to update these to:

- ‘low-temperature heat pump space heater’ means a heat pump space heater, or heat pump combination heater, that is declared capable of being used in a low-temperature application

- ‘medium-temperature heat pump space heater’ means a heat pump space heater, or heat pump combination heater, that is declared capable of being used in a medium-temperature application

- ‘high-temperature heat pump space heater’ means a heat pump space heater, or heat pump combination heater, that is declared capable of being used in a high-temperature application

- ‘low-temperature application’ means an application where the heater delivers space heating at an indoor heat exchanger outlet temperature of 35°C at reference design temperature, and at the water outlet temperature specified for each set of part load conditions in the rows marked ‘LT’ in Table 4B in Annex 3

- ‘medium-temperature application’ means an application where the heater delivers space heating at an indoor heat exchanger outlet temperature of 55°C at reference design temperature, and at the water outlet temperature specified for each set of part load conditions in the rows marked ‘MT’ in Table 4B in Annex 3

- ‘high-temperature application’ means an application where the heater delivers space heating at an indoor heat exchanger outlet temperature of 65°C at reference design temperature, and at the water outlet temperature specified for each set of part load conditions in the rows marked ‘HT’ in Table 4B in Annex 3

We propose updating these definitions, as set out in regulation 12(5) of the draft SI. These definitions should mean that if a single heat pump can operate in more than one temperature application, the MEPS requirements apply at all relevant temperatures. We are keen for views and evidence in responses to questions 2-14 and 16 as to whether MEPS should apply to all heat pumps at each temperature application that a heat pump is capable of operating at.

18. Do these definitions adequately cover all current and future heat pumps? Yes/No/Don’t know. If not, what elements do you recommend should be changed and why? Please provide evidence or reasoning to support your answer.

19. Do you agree with the proposed definitions for low-temperature, medium-temperature and high-temperature heat pump space heater? Yes/No/Don’t know. If not, what elements do you recommend should be changed and why? Please provide evidence or reasoning to support your answer.

20. Do you agree with the proposed definitions for low-temperature, medium-temperature and high-temperature application? Yes/No/Don’t know. If not, what elements do you recommend should be changed and why? Please provide evidence or reasoning to support your answer.

Chapter 3: Hot water storage

Introduction

Hot water storage is a necessary part of nearly all heat pump heating systems. Standard heat pumps do not provide hot water on demand like combination boilers. As such, these heat pump systems, as well as heat only and system boilers, require a way of storing hot water for when it is required.

Ecodesign regulations have been used to improve the performance of hot water storage tanks (or ‘cylinders’ as they are commonly referred). In 2017, the regulations were updated to require all hot water storage tanks to meet a minimum performance rating of C.

This chapter seeks views about what changes and signals could be made through amending ecodesign (814/2013) and energy labelling regulations (812/2013) and, respectively to encourage or require a market shift towards cylinders compatible with low-temperature heating systems, such as heat pumps. This will not be implemented in this round of amendments, so no changes have been made in the draft SI accompanying this consultation. We will reconsult on any proposed later changes to ecodesign following feedback on this section.

Context

Hot water cylinders can be direct or indirect. A direct cylinder is directly heated via an electric immersion heater (and does not work with an integrated hot water system), whereas indirect cylinders heat the water at the point of storage (via a coil running through the cylinder) and therefore can be used with such systems.

Hot water cylinders can also be vented or unvented. The water supply for vented cylinders is via a vent pipe from a large tank of cold water stored at a higher source (usually a loft). Unvented cylinders are connected to the mains, which runs at a higher pressure attainable than vented cylinders. However, unvented cylinders aren’t always compatible with modern power showers and mixers, and since unvented cylinders are linked directly to the mains, these will not provide hot water if mains are turned off.

Previous regulation changes have focused on the minimum efficiency of hot water storage tanks. The Improving Boiler Standards and Efficiency consultation proposed to raise the minimum efficiency class for all hot water storage tanks to B. However, respondents highlighted challenges around the cost impacts and space requirements inherent in these proposals. Therefore, the government is not planning to implement this proposal.

The previous focus on raising energy efficiency rating means there has been less focus on the compatibility of hot water cylinders with a heat pump or other low-temperature hydronic heating systems. Achieving such compatibility could both enable low-temperature operation of existing systems and / or futureproof cylinders for use with other low-temperature appliances (such as heat pumps) by removing the need to replace cylinders as part of upgrades to such systems.

Compatibility with heat pumps and low-temperature systems

Respondents to the Improving Boiler Standards and Efficiency consultation focused on hot water cylinder stratification as key to supporting heat pump compatibility. In a stratified cylinder, the separation of the warm water takes place at different heights according to its temperature. The water at the top of the cylinder has the highest temperature, and the water at the bottom, the lowest.

Cylinders using stratification are a faster, more energy efficient and economical way to provide hot water compared to a cylinder without the feature. Cylinders with greater stratification were seen by respondents as being more compatible with heat pumps as they were better suited for low-temperature operation.

Respondents also raised the issue of coil sizing. Heating coils are used to heat water inside indirect water heating cylinders. If the coil of an existing cylinder is too small, a cylinder in a low-temperature heating system will take longer to reheat, perhaps meaning hot water supply is insufficient to meet demand. It was therefore suggested that the government could provide advice or set requirements related to coil size.

As such, the government would welcome further views on how stratification and coil size requirements could be regulated to better support cylinder compatibility with low-temperature heating systems and heat pumps, as well as other suggestions to improve such compatibility.

One option could be to include coil sizing requirements in the regulations. In responses to the Improving Boiler Standards and Efficiency consultation, it was suggested that the government could provide advice/regulate about the correct coil size (used to heat water inside indirect water heating cylinders) with some respondents suggesting the minimum coil size for a range of hot water cylinder sizes, i.e. 90-150L coil size suitable for 6 kW heat pumps, 150L-210L coil size for 5,6,8,10 kW heat pumps, and 210L-300L coil suitable up to 17 kW heat pumps.

An alternative option, given the diverse range of hot water cylinders that are low-temperature systems / heat pump compatible, is to make better use of the energy labelling. For example, a low-temperature compatibility mark could be introduced to cylinder energy labels, to denote products achieving a base level of compatibility. Another option would be to provide an efficiency uplift to the efficiency rating of cylinders where they are deemed to have an appropriate degree of stratification for use as part of a low-temperature system. Improving cylinder energy labelling in this way would enable installers and consumers to make more informed choices when replacing hot water cylinders and to help futureproof their purchase.

If we are to later change hot water cylinder regulations (814/2013) or amend the energy label (812/2013), it would be useful to have a definition which will enable government to define a more heat pump / low-temperature compatible hot water cylinder, compared to a less compatible model. The definition for a low-temperature compatible hot water storage tank could make reference to specific features, such as stratification and coil sizing. We welcome views on this definition.

21. How should regulations define a low-temperature compatible hot water storage tank? What are the key constituent elements of this definition? Please provide evidence or reasoning to support your answer.

22. Do you agree that a heat pump compatible symbol on an energy label would help futureproof hot water cylinders? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

23. Should stratification be incorporated into the requirements of ecodesign (812/2013), to support hot water cylinder heat pump compatibility? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

24. Should coil sizing be incorporated into the requirements of ecodesign (812/2013), to support hot water cylinder heat pump compatibility? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

Chapter 4: Hybrid heat pumps

Introduction

Hybrid heat pumps consist of multiple heat sources (one of which is a heat pump) operating together to create a single heating system. Because they are a type of space heater, they fall within the scope of ecodesign and energy labelling legislation for space heating. However, they are not currently categorised as a specific type of appliance and there is no definition or minimum efficiency criteria in the current legislation.

The government believes that hybrid heat pumps can play an important role in heat decarbonisation, and we will continue to consider the necessary conditions to enable their installation. Notably, however, significant carbon savings from hybrid heat pumps are dependent on a range of factors including system design, a building’s thermal characteristics and consumer behaviour.

This consultation proposes two new safeguards vital to creating a solid foundation for a wider market for hybrid heat pumps and to help ensure that systems are designed to reduce energy use and deliver carbon and bill savings. Firstly, we propose a clear definition for hybrid heating systems and hybrid heat pumps, for the purposes of ecodesign and energy labelling regulations. By defining these products such that they are required to have similar characteristics and capabilities, this can improve clarity, consistency and comparability between products for consumers. Secondly, we propose a new minimum seasonal space heating energy efficiency for hybrid heat pumps. MEPS for hybrid heat pumps can help futureproof this technology and ensure that new products placed on the market are effective and efficient and are therefore more likely to deliver real-world carbon savings.

We acknowledge that other factors may have a role to play in enabling and encouraging hybrid heat pumps to be used in a way that maximises bill savings for consumers and the delivery of carbon savings, through heat pump-led utilisation. This could include relative gas and electricity prices, system control capability to respond to price signals, installation standards and guidance, and consumer information and advice. These are beyond the scope of ecodesign and energy labelling regulations, and therefore beyond the scope of this consultation.

Context

In the consultation on Improving Boiler Standards and Efficiency, the previous government expressed its hope that hybrid heat pumps may be able to play a substantive role beyond 2028, if they are compatible with net zero or if they act as a stepping-stone to other technologies that are compatible with net zero (such as standalone heat pumps). The consultation set out a range of risks and benefits of hybrid heat pumps and sought views on this.

We understand that the potential benefits of widespread deployment of hybrid heat pumps may be significant and that switching from a fossil fuel boiler to a hybrid heat pump could:

- reduce fossil fuel use – reducing carbon emissions while also reducing dependency on volatile fossil fuel prices and increasing energy security

- reduce consumers’ energy bills – due to an efficiency increase (from 92% for gas boilers, to above 125% in line with our minimum efficiency proposals), especially if combined with actions to rebalance electricity costs

- contribute towards growth of the heat pump supply chain, UK manufacturing of low-carbon appliances, and upskilling installers

Additionally, in comparison to standalone heat pumps, hybrid heat pumps can:

- allow a more gradual transition for consumers – increasing familiarity with a new technology and allowing more time to improve the thermal efficiency of homes before installing a low-temperature heat pump

- be suitable for somewhat space-constrained properties, when combined with a combi boiler, as they do not require space for a hot water tank

- potentially reduce or delay the need for additional generation capacity and electricity grid expansion and reinforcement, given their potential to reduce peak electricity demand by switching between fuel sources

Compact hybrid heat pumps – consisting of a heat pump and a natural gas boiler within a single unit and without an outdoor unit – have the potential to deliver further benefits as they may be suitable for space constrained homes, as they do not require external space for a heat pump’s outdoor unit (nor space for a hot water tank). However, there are also challenges, risks and issues specific to compact hybrid heating systems – mainly around their size and weight and the requirement for an additional flue – making them not an exact like-for-like replacement for a combination boiler.

We appreciate that there are also some challenges and drawbacks to hybrid heat pumps generally, including how best to ensure that increasing deployment of hybrid heat pumps does not encroach on the installation of standalone heat pumps and the risk that keeping too many technology options open can cause diseconomies and decision paralysis.

The government will continue to develop and communicate its position on hybrid heat pumps, to provide both consumers and industry with certainty and stability and is keen to continue to work with industry to further build our evidence base. We will monitor product and market developments in the UK and product and regulatory developments in related markets and continue to work with stakeholders and international colleagues to learn insights about the deployment of hybrid heat pumps.

Terminology and definitions

Current ecodesign (813/2013) and energy labelling (811/2013) legislation does not include a definition of hybrid heating systems. Without one, we will not be able to set minimum efficiency requirements and there is a risk of miscommunication and greenwashing, as a range of products could be described as a ‘hybrid heat pump’.

We have identified a number of key elements to a definition, for use in ecodesign and energy labelling legislation, which are set out below.

Clarity – Any legislative definition needs to be easy to understand and apply so that manufacturers can easily determine whether their product, or group of products, would fall in- or out-of-scope of this definition.

Enabling variety – An array of hybrid heat pumps is currently available. So as not to hinder innovation, or create loopholes in our minimum requirements, we need a definition which can encompass this wide variety of products. This should be irrespective of the fuel used by the alternate heat source, whether and how the heat sources are integrated (whether they are single units or groups of products placed on the market as a package), and whether the heat pump delivers water heating. Therefore, the definition needs to cover:

- packaged hybrid heat pumps – Separable boiler and heat pump products packaged to create a single heating system

- integrated hybrid heat pumps – Where parts of a heat pump and alternate heat source are integrated within a single unit. ‘Compact’ hybrid heat pumps are a sub-set of integrated hybrid heat pumps – to describe systems where all of the of the heat sources are housed within a single unit

As this legislation takes effect at the point a product is placed on the market it will not need to cover heat pumps installed alongside pre-existing heating systems to create a single hybrid heating system.

Ensuring quality – We intend to include in the definition any elements of a hybrid heat pump which are essential to the effectiveness of the system, such as a single master control to operate and optimise how the component heat sources operate together. This definition would, therefore, set the bar as to what a hybrid heat pump needs to contain or be capable of.

Futureproofing – New types of hybrid heat pumps, not currently widely available, may enter the market and/or have a significant role to play in heat decarbonisation in the future. We need to ensure our definition is broad and flexible enough to encompass new innovations.

We, therefore, propose adding the following definition into Article 2 of ecodesign (813/2013) and energy labelling (811/2013) regulations, as set out in regulation 12 of the draft SI, (18H), so that a hybrid heat pump system refers to a system of space heating, or space and water heating, that contains an electric heat pump, a fuel boiler space heater or a fuel boiler combination heater, and a master control which determines, based on operating conditions, the heat output of each of the heaters.

To reduce duplication, we also propose updating the definition of a ‘heat pump space heater’ to remove the reference to supplementary heaters using the combustion of fuels.

Please review regulation 12 of the draft SI.

25. Do you agree with (a) the proposed definition of hybrid heat pump and (b) adjusting the definition of a heat pump space heater to reduce duplication? Yes/No/Don’t know. If not, what elements do you recommend should be changed and why? Please provide evidence or reasoning to support your answer.

Minimum Energy Performance Standards

Currently there is little clarity for manufacturers as to which standards to use to calculate a hybrid heat pump’s seasonal space heating energy efficiency, and whether the declared efficiency should reflect the total system’s efficiency, or the component technologies’ efficiencies. Therefore, it is challenging for consumers to easily compare different hybrid heaters, or easily understand the difference in efficiency between a standalone heat pump or hybrid heat pump.

Minimum energy performance standards (MEPS) and labelling have historically been successful in reducing energy use and lifetime costs by removing the least efficient products from the market and empowering consumers to purchase more efficient products. Setting MEPS for hybrid heat pumps through ecodesign (813/2013) is an important step in creating a solid foundation for a market for hybrid heat pumps and preventing low efficiency products from being placed on the market in the future. As there is still a relatively small existing market for hybrid heat pumps, we are also mindful that any new MEPS need to avoid stifling this emerging market by setting too high standards too early.

The compliance with MEPS is based on the product’s seasonal space heating energy efficiency, which reflects the performance under laboratory test conditions and does not necessarily reflect in situ performance. Therefore, in addition to setting MEPS, we intend to continue working to enable, encourage and incentivise high-quality installations and heat pump-led operation to deliver real-world carbon savings.

The consultation on Improving Boiler Standards and Efficiency sought views on the establishment of a minimum efficiency for hybrid heat pumps through ecodesign and energy labelling legislation, and at what level this should be set. Many respondents were supportive of MEPS for hybrid heat pumps, but referred to previous European Commission proposals, which have since been updated, and some assumed different primary energy factors for electricity. The previous government’s response reaffirmed the intention to set a minimum efficiency for hybrid heat pumps, but to provide another opportunity to gather views on a specific value.

The government now proposes to set a MEPS for medium-temperature application hybrid heat pumps of 125% (assuming a primary energy factor of 1.9) from mid-2027 in ecodesign (813/2013), as set out in regulation 18 of the draft SI.

We understand 125% seasonal space heating energy efficiency could be met by many of the hybrid heating systems currently available, and therefore mid-2027 provides sufficient lead-time for manufacturers. This value also complements our MEPS for heat pumps (as stated in Chapter 2) and boilers (as stated in Chapter 5).

We do not propose to set separate specific standards for hybrid heat pumps operating at low-or high-temperature, as we expect that medium-temperature application (of 55°C), will most closely resemble in situ operation.

We propose that BS EN 14825:2022 and BS EN 15502-2-3:2023[footnote 14] are reliable, accurate and reproducible methods that take into account the generally recognised state-of-the-art methods for measurements and calculations, and, therefore, are appropriate to be used for the purposes of compliance and verification of compliance of a hybrid heat pump’s seasonal space heating energy efficiency (depending on which heating system is the supplementary heater). We also propose to accept both separated and combined test methods (as described in BS EN 14825:2022) to calculate the seasonal space heating energy efficiency. The combined method provides the benefit of including any impacts of the control’s decision-making in the calculation while the separated test method allows more combinations of heat pumps and alternative heat sources to be approved to operate together without the need to test all combinations separately.

26. Do you agree that we should set a MEPS at 125% for hybrid heat pumps? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

27. Do you agree that this should be for medium-temperature (55°C flow temperature) hybrid heat pumps? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

28. Do you agree that the implementation of new MEPS for hybrid heat pumps should align with the tier 1 heat pump MEPS proposals, taking effect from mid-2027? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

29. Do you agree that either test methods (combined or separate) should be acceptable for testing the seasonal space heating energy efficiency for hybrids heat pumps? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

30. Do you agree that BS EN 14825:2022 and BS EN 15502-2-3:2023 are appropriate means of calculating the seasonal space heating energy efficiency for a hybrid heat pump despite the fact that they are currently behind a paywall? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

Information required

In addition to stating the calculated seasonal space heating energy efficiency of the hybrid heat pump, we propose that hybrid heat pumps should have similar information requirements as for boilers and heat pumps. However, there are some elements of information requirements as set out in energy labelling (811/2013), Annex V, Tables 7 and 8 and ecodesign (813/2013), Annex II, Tables 1 and 2 which may not be calculable for hybrid heaters tested through the combined method. Therefore, we propose a new table of information requirements to be added to energy labelling (811/2013) as set out in regulation 30 of the draft SI, and to ecodesign (813/2013) as set out in regulation 18 of the SI, specifically for hybrid heaters as per Table 1 below. This includes small changes in information requirements to reflect the operation of hybrid heat pumps and align with the latest British Standards Institute (BSI) testing standards on:

- which is the primary (vs supplementary) heat source

- what standard is used for testing the system

- the rated heat output of heat pump (Php) and boiler (Pfb), which correspond to Prated and Psup (or vice vera)

- switch temperature boiler off (Tfb,off), rather than bivalent temperature (Tbiv)

- switch temperature heat pump on (Thp,on), rather than operational limit temperature (TOL)

Table 1: Information requirements for hybrid heaters

Model(s): [information identifying the model(s) to which the information relates]

Primary heat source: [heat pump/fuel boiler]

Testing Standard used:

Air-to-water heat pump: [yes/no]

Water-to-water heat pump: [yes/no]

Brine-to-water heat pump: [yes/no]

Low-temperature heat pump: [yes/no]

Heat pump combination heater: [yes/no]

B1 boiler: [yes/no]

Boiler combination heater: [yes/no]

| Item | Symbol | Value | Unit |

|---|---|---|---|

| Rated heat output of heat pump (at temperature Thp,on) | Php | x | kW |

| Rated heat output of boiler (at temperature Tfb,off) | Pfb | x | kW |

| Seasonal space heating energy efficiency | ƞs | x | % |

Declared hybrid heat pump capacity for heating for part load at indoor temperature 20 °C and outdoor temperature Tj:

| Item | Symbol | Value | Unit |

|---|---|---|---|

| Tj = – 7 °C | Pdh | x,x | kW |

| Tj = + 2 °C | Pdh | x,x | kW |

| Tj = + 7 °C | Pdh | x,x | kW |

| Tj = + 12 °C | Pdh | x,x | kW |

| Switch temperature boiler off | Tfb,off | x | °C |

| Switch temperature heat pump on | Thp,on | x | °C |

| Cycling interval capacity for heating | Pcych | x,x | kW |

| Degradation co-efficient(b) | Cdh | x,x | — |

Declared coefficient of performance or primary energy ratio for hybrid heat pump for part load at indoor temperature 20 °C and outdoor temperature Tj:

| Item | Symbol | Value | Unit |

|---|---|---|---|

| Tj = – 7 °C | COPd or PERd | x,xx or x,x | – or % |

| Tj = + 2 °C | COPd or PERd | x,xx or x,x | – or % |

| Tj = + 7 °C | COPd or PERd | x,xx or x,x | – or % |

| Tj = + 12 °C | COPd or PERd | x,xx or x,x | – or % |

| Cycling interval efficiency | COPcyc or PERcyc | x,xx or x,x | – or % |

| Heating water operating limit temperature | WTOL | x | °C |

Power consumption in modes other than active mode:

| Item | Symbol | Value | Unit |

|---|---|---|---|

| Off mode | POFF | x,xxx | kW |

| Thermostat-off mode | PTO | x,xxx | kW |

| Standby mode | PSB | x,xxx | kW |

| Crankcase heater mode | PCK | x,xxx | kW |

Other items:

Capacity control: fixed/variable

| Item | Symbol | Value | Unit |

|---|---|---|---|

| Sound power level, indoors/outdoors | LWA | x/x | dB |

| For air-to-water heat pumps: Rated air flow rate, outdoors | — | x | m3/h |

| For water-/brine-to-water heat pumps: Rated brine or water flow rate, outdoor heat exchanger | — | x | m3/h |

| Emissions of nitrogen oxides | NOx | x | mg/kWh |

For hybrid heat pump combination heater:

| Item | Symbol | Value | Unit |

|---|---|---|---|

| Declared load profile | x | — | — |

| Daily electricity consumption | Qelec | x,xxx | kWh |

| Water heating energy efficiency | ƞwh | x | % |

| Daily fuel consumption | Qfuel | x,xxx | kWh |

Contact details:

Name and address of the manufacturer or its authorised representative.

31. Do you agree with the information requirements for hybrid heat pumps as per Table 1 (regulation18(6) Table 2A of the Draft SI)? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

32. Are there any elements missing from Table 1 (regulation18(6) Table 2A of the Draft SI) that should be added? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

33. Are there any elements in Table 1 (regulation18(6) Table 2A of the Draft SI) that should be removed? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

We also propose to update the information requirements for the product brochure and other literature provided with the product to clarify the information requirements for hybrid heat pumps. The current product fiche is found in the energy labelling legislation 811/2013, Annex IV and 813/2013, Annex II.

The role of hybrid heat pumps in heat decarbonisation

The Energy-related Products Policy Framework, published in November 2021, referenced the possibility of phasing out the installation of standalone fossil fuel boilers by setting minimum efficiency requirements for all space heaters of more than 100%. Similar proposals were also made by the European Commission in 2023. Only a small number of respondents to the consultation on Improving Boiler Standards and Efficiency commented on this, with an even split of views.

On consideration of the responses to previous consultations received, the potential level of disruption caused by this policy, the range of alternative technologies to decarbonise heat, and what we currently understand to be the relative risks and benefits of widespread deployment of hybrid heat pumps, the government is not currently proposing to implement a minimum efficiency for all space heaters of more than 100%. However, we are keen to gather views, both on to what extent we should enable and encourage hybrid heat pump installations and whether we should reconsider setting a minimum efficiency for all space heaters of more than 100%.

34. On the balance of pros and cons, should we encourage and enable hybrid heat pumps to play a significant, and potentially widespread, role in heat decarbonisation? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

35. Do you agree that we should not currently be looking to introduce mandating a minimum efficiency of more than 100%, which would, in effect, phase out installation of standalone fossil fuel boilers? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

Part 2: Reducing fossil fuel demand

Despite the range of government policies aimed at growing the clean heat market, it is estimated that there will still be over 10 million boiler installations over the next decade. We want to ensure that consumers purchasing these new fossil fuel boilers can benefit from raised in-home performance.

Despite being a mature technology there is more that can be done to ensure that condensing boilers operate as efficiently as possible while ensuring consumer comfort and control. The government aims to ensure households that still use fossil fuel system get energy bills as low as possible. The more efficient the operation of the fossil fuel system the lower consumer bills and the less carbon will be emitted.

The new energy efficiency proposals for gas boilers are expected to deliver average savings of over £30 per year over the 15-year life of the boilers once the full requirements are introduced. In advance of this, the first tranche of proposals expect to see gas boiler households benefit in a £19 yearly saving. These changes quickly offset the increased capital costs of approximately £50.

The significant number of installations means the average anticipated efficiency of improvement could translate into carbon savings which can contribute to legally binding carbon budgets. The boiler and temperature control proposals in this consultation are expected to save 1.9 MtCO2e in Carbon Budget 5 and 3.5 MtCO2e in Carbon Budget 6 and to reduce reliance on imported energy.

Boiler Plus Standards

In 2018, changes were made to Approved Document L of the English Building Regulations intended to improve the in-situ efficiency of boilers. The aim was to improve consumer comfort and ensure they benefit from increasingly energy efficient heating systems. These changes became known as the ‘Boiler Plus Standards’[footnote 15]. The standards applied to boiler replacements and installations in existing dwellings.

According to these standards, when replacing any type of oil and gas boiler, installers should fit boiler interlock and a time and temperature control. There are additional standards for installations of gas boilers: a MEPS for gas boilers of 92%, and, for combination gas boilers, a standard stating that one of four additional energy efficiency measures:

- Flue Gas Heat Recovery Systems (FGHRS)

- Weather Compensators

- Load Compensators

- Smart controls with automation and optimisation functions

Gas Safe Register certified installers, to ensure they are fulfilling the expectations associated with self-certification of a gas boiler installations, will need to follow the standards above or their installations will need to meet the expected standards in Approved Document L Volume 1 or demonstrate equivalence.

With the exception of FGHRS, these measures are types of heating control that are intended to reduce gas consumption either by reducing the boiler’s operating time/periods or helping the boiler operate using lower flow temperatures.

Boiler Plus Review

The Boiler Plus Review (2021) was an initial policy review into the standards. It was intended to check the levels of compliance with the Boiler Plus Standards as well as understanding how the standards impacted manufacturers, installers and consumers. The review was also an opportunity to assess if it was appropriate for the aspects of the standards which applied only to combination gas boilers to be applied to all gas boiler types.

The review found the standards had been successful in removing the lowest tested efficiency boilers from the market. There had also been a significant increase in the additional energy measures being installed with gas combination boilers, in particular smart controls.

The review did, however, also highlight several barriers to the delivery of the policy objectives and suggested ways in which policy could develop further. For example, there were concerns of potential non-compliance due to the lack of monitoring around the installation of additional energy measures with gas combination boilers. A consumer engagement gap was also raised due to limited awareness of temperature control functions and of the Boiler Plus standards. As the functions of temperature controls vary, so do the benefits to consumers. These benefits can be further impacted due to the operational protocols that are in place within both the boiler and the control, as these can affect the control’s ability to communicate with and adjust the boiler output. The proposals we set out in the following chapters have taken account of these findings.

Estimated savings

The previous government’s response to the Improving Boiler Standards and Efficiency consultation (2024), committed to several policies including technical improvements to gas boilers to increase system efficiency. We recognise the benefits of these policies, and we are proceeding to consult on their implementation.

It is estimated that the total package of policy proposals for gas boilers (outlined in Chapter 5) and the proposals for controls (outlined in Chapter 6) will provide around a £30 bill saving per year for the average household. The proposals are also expected to deliver savings for oil boiler users. These policies will enable fossil fuel boilers to operate closer to their lab-tested efficiency levels.

Proposals

In Part 2 we are consulting on the regulatory implementation of the following measures:

- all gas combination boilers (≤45 kW) to be able to modulate their maximum output down to 15% without on/off cycling by mid-2028

- all oil combination boilers (≤45 kW) to be capable of modulating their heat output down to 30% of their maximum heat output without on/off cycling, by mid-2028

- all gas combination boilers to be supplied with a 60 degrees Celsius (°C) low flow temperature factory default setting by mid-2026

- raising GB requirements so that temperature control Classes I-III are no longer sufficient by mid-2026

- introduce the definition of open protocols into the regulations

- all temperature controls and gas combination boilers to use open protocols by mid-2026

- boilers and temperature controls must, when placed on the market, be accompanied by information about which open protocols they can use

- formally introduce temperature control Classes definitions into the regulations

- all oil combination boilers to use open protocols by mid-2028

Chapter 5: Fossil fuel boilers

Introduction

Historically, government regulation has been important in driving adoption rates for new, more efficient technologies in the boiler market, spurring innovation and technological development.

Previous changes to minimum boiler efficiency for gas boilers have largely focused on raising minimum tested efficiency and sought to ensure that gas boilers are operating as efficiently as possible in the home to reduce the gap between tested and advertised efficiency levels. This was achieved through the use of additional technology, such as heating controls, and installations practices. However, we still believe there is a performance gap between boilers under test conditions and in-home boiler efficiency which these policies seek to address.

This chapter will consult on measures that are expected to further improve the energy efficiency performance of a gas or an oil boiler in the home, including by mitigating for boiler oversizing and better providing for low-temperature operation of systems in the home.

Context

Updates to Approved Document L of the Building Regulations in 2021 included standards in sizing all parts of the heating system including pipework and emitters to meet a property’s heat demand year around, at a flow temperature of 55°C or lower. It also set standards gas combination boilers to be able to modulate down to the typical heating load of the dwelling.

We recognise the benefits of low-temperature systems for consumers including bill savings, increased system efficiency and reduced carbon emissions. The department is working to implement mandatory low-temperature training for all gas boiler installers to ensure that all consumers can benefit from this.

Wider combination boiler modulation to tackle oversizing

Combination boilers are the most common boiler type sold on the UK market, making up around 80% of all gas boiler sales and a large portion of oil boilers. These boilers tend to be attractive to consumers as they can meet hot water demand instantly and do not require a hot water tank, saving on space.

Correct boiler sizing is a significant factor in ensuring that household energy demands are met for space heating and domestic hot water. However, the anticipated hot water demand can heavily influence the sizing of the boiler and can result in a boiler that is significantly oversized when compared to the space heating demand of the home.

The average property in the England has a space heating demand of 6 kW, whereas the most commonly installed gas combination boilers have a maximum space heating output over 24 kW.[footnote 16] As a result, system/heat only boilers, which are often far smaller in a heat output and yet can provide sufficient hot water with this smaller output, are often recommended for dwellings with a larger hot water demand.

Space heating demand is also calculated by considering winter temperatures, so the system can meet peak demand. But this means the system is oversized for requirements in milder temperatures in the shoulder seasons.

If a boiler is oversized, then boiler cycling is more likely to occur. Cycling is where a boiler repeatedly turns itself on and off to regulate its output to maintain the set temperature. This can cause wear and tear, reducing the lifespan of the boiler and its efficiency.

Updated Buildings Regulations in 2021 state that heating systems should not be ‘significantly oversized’ and “when a gas combination boiler is used, the boiler type selected should be selected to modulate down to the typical heating load of the dwelling”.[footnote 17]

Wide boiler modulation can help address the impacts of boiler oversizing. A modulation boiler can turn down its output to meet heat demand rather than needing to turn the system on and off continuously. For example, if a 30 kW boiler only requires 10 kW of heat, then it can modulate its output down to only use the 10 kW that is required. By turning down its output, the boiler is only using the energy that is necessary to meet heating demand and is doing so without on-off cycling.

Noting the above, and with consideration of stakeholder views gathered through the Improving Boiler Standards and Efficiency consultation, the government is proposing that from mid-2028 all new gas combination boilers (≤45 kW) placed on the GB market should be able to modulate down to at least 15% of their maximum output without on/off cycling. By maximum output, the regulations mean the maximum kW output of the boiler i.e. for a 30 kW even if the heating output is capped at 24 kW the maximum output is 30 kW. However, if this requirement should be focused solely on the maximum heating output of gas combination boilers, we would welcome views. The latter approach focusing on heating output has been taken with oil combination boilers.

Please review regulation 12; regulation 13(3); regulation 18(3), (4) of the draft SI.

36. Do you agree that all new gas combination boilers (≤45 kW) placed on the GB market should be able to modulate their maximum output down to 15% without on/off cycling by mid-2028? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

Larger boilers, due to their higher levels of absolute output, may be able to modulate to lower proportions of their total output than their smaller counterparts. It is for this reason, that the government is considering an extension to the above modulation requirement for all gas combination boilers placed on the GB market, such that in the future all larger gas combination boilers, 45 kW ≥ 32 kW, must be able to modulate their maximum output down to 10% without on/off cycling.

37. Do you agree that the government should consider introducing an extension for the modulation requirements such that larger domestic-scale gas combination boilers (45 ≥ 32 kW) placed on the GB market should be able to modulate their maximum output down to 10% without on/off cycling? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer. If you support an increased modulation requirement for larger domestic-scale combination boilers, please suggest a date for when this should come into force.

Oil boilers can also utilise modulation functions instead of on/off cycling. Whilst modulating oil boilers are not prevalent in the current market, newer models are being placed on the market that are capable of modulation. This now means more off-gas grid consumers can now benefit from more efficient heating systems. Given the early stages of market maturity, we are proposing that all combination oil boilers (≤45 kW) be capable of modulating their heat output down to 30% of their maximum output without on/off cycling by 2028.

Please review regulation 12; regulation 13(3); regulation 18(3), (4) of the draft SI.

38. Do you agree that all combination oil boilers (≤45 kW) should be capable of modulating their heat output down to 30% of their maximum heat output without on/off cycling, by mid-2028? Yes/No/Don’t know. Please provide evidence or reasoning to support your answer.

Gas Combination boiler flow temperatures: Default low flow temperature factory settings

By operating at lower flow temperatures, heating systems can run more efficiently, for example, by allowing boilers to run in condensing mode. This enables the boiler to recover latent heat that would otherwise be lost, thereby using less fuel to meet heat demand. Lowering the boiler’s flow temperature will improve its efficiency and ensure that it is performing to the advertised performance.

In fact, lowering a combination boiler’s flow temperature could save a consumer over £60 a year. Previously issued guidance recommends lowering the flow temperature to 60 degrees Celsius (°C) or 65 degrees Celsius (°C) for those over 65 years old or with pre-existing health conditions[footnote 18].

Previous updates to Part L within the Building Regulations have set standards for new or replacement wet central heating systems to be designed to operate at a maximum flow temperature of 55 degrees Celsius (°C) where possible.

Beyond this consultation, we are working with industry to implement low-temperature training for gas boiler installers to meet these standards within Building Regulations. To be registered with a government authorised competent person scheme (CPS), organisations and individuals need to demonstrate that they meet the relevant Mandatory Technical Competence (MTC) criteria. These criteria define the competence requirements for CPS installers, allowing approved persons to self-certify the compliance of controlled work in buildings that are subject to the regulations. A person operating under a CPS operator has a duty to comply with all aspects of the regulations not just the core aspects of the work being undertaken. Updates to the MTC criteria will ensure that low-temperature training becomes a mandatory requirement for gas boiler installers.

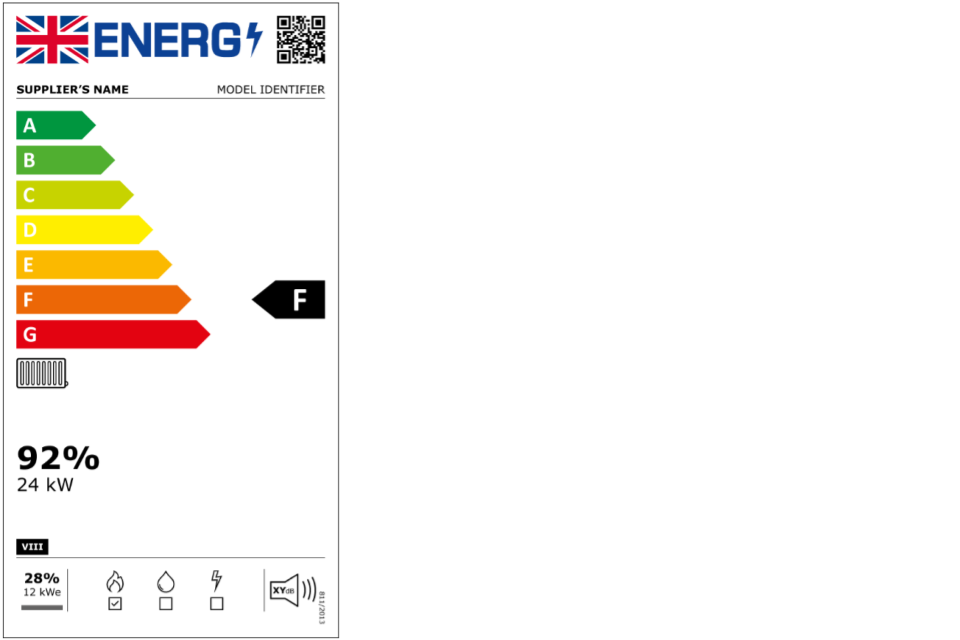

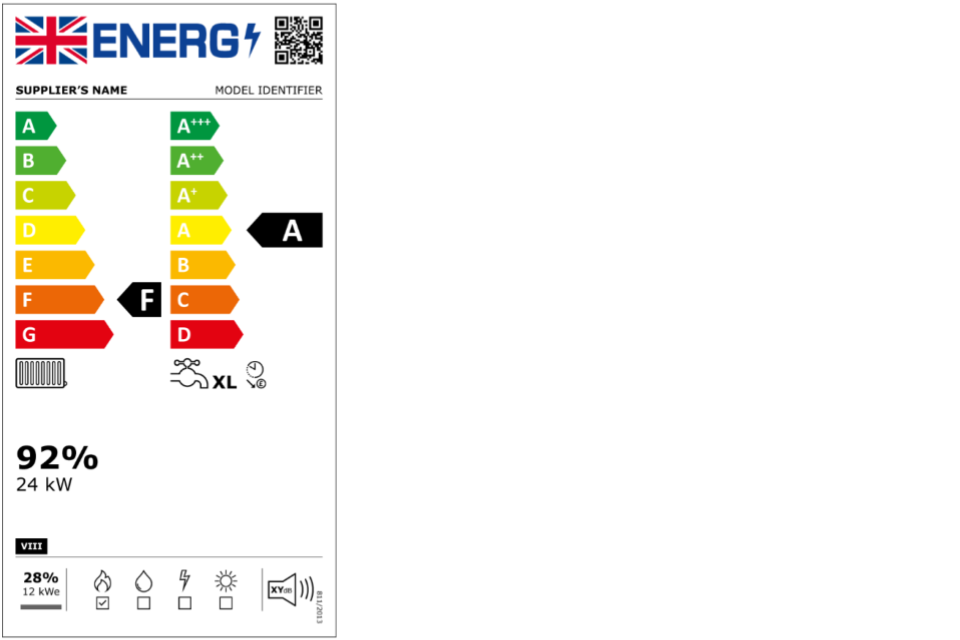

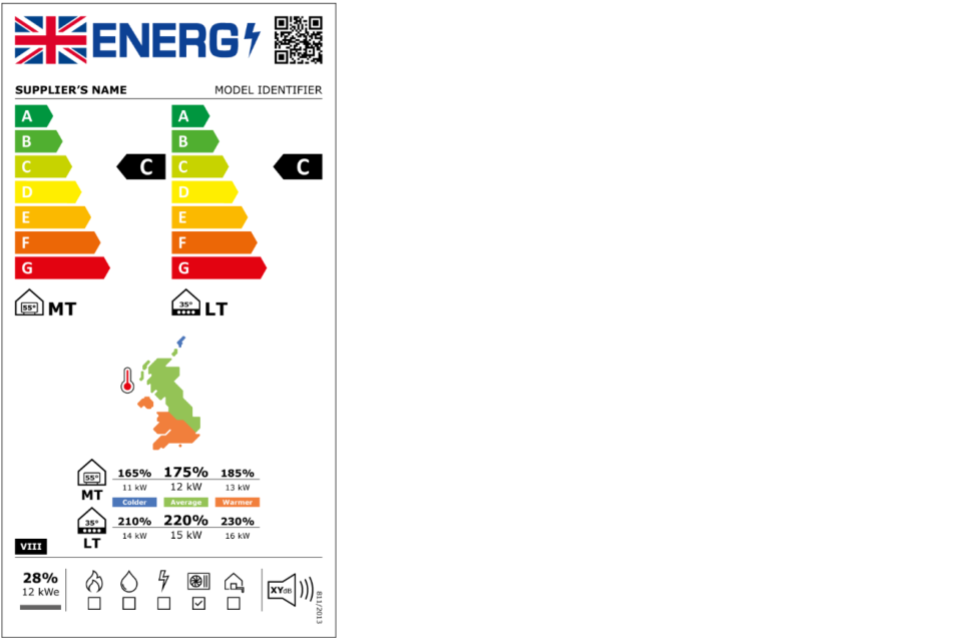

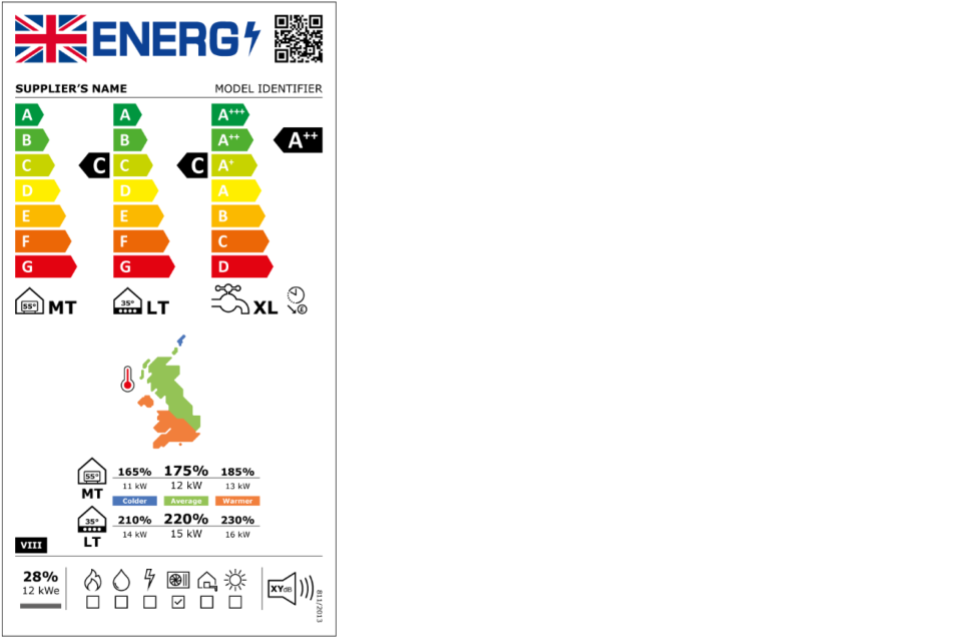

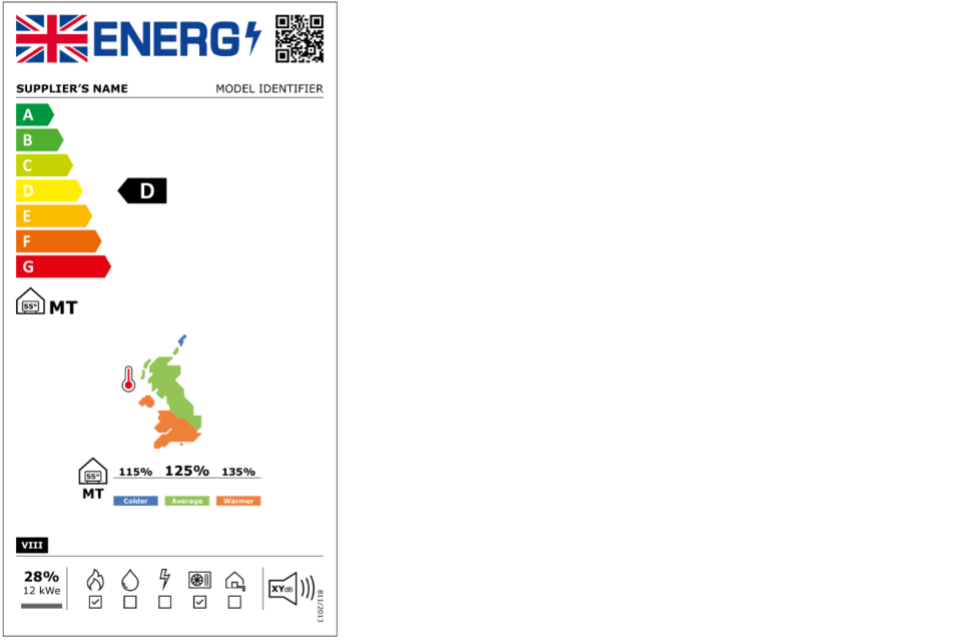

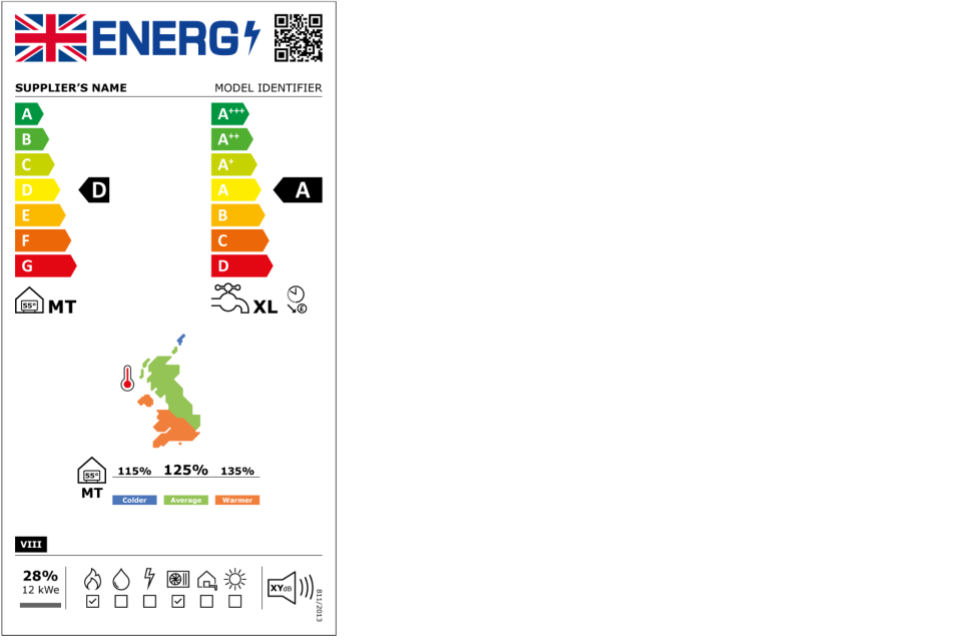

The current standards in Approved Document L1 are for when full heating systems are replaced. We acknowledge that a flow temperature of 55 degrees Celsius (°C) would not be suitable for all households, where it is only the boiler being replaced. The government is therefore, proposing that all combination boilers should be supplied with a default low-temperature factory setting at 60 degrees Celsius (°C) by 2026. We note that for those over 65 or with pre-existing health conditions, a slightly higher flow temperature of 65°C may be more suitable to ensure a home warms more quickly, as set out in previous guidance.