From monitoring climate change to avoiding space debris - pioneering space technology gets government cash boost

5 UK organisations have been awarded a total of £300,000 from the UK Space Agency to speed up the development of innovative space technology

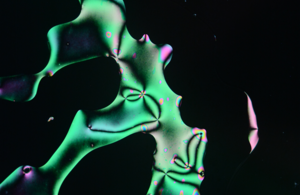

Credit: Leeds Uni

Recipients include the University of Leeds, which will develop 3D printing methods and liquid-crystal technology, similar to that in our television screens at home, to develop far-infrared sensors for studying climate change and star formation.

Another project, led by Rocket Engineering in London, will create a compact propulsion system the size of a house brick for use in nano and small satellites. The engines use electromagnets to enable the satellites to move for in-orbit spacecraft servicing or space debris mitigation.

The funding comes from the UK Space Agency’s National Space Technology Programme (NSTP), which supports development of space technologies, encourages collaboration between industry and academia, and encourages new entrants to the space sector.

Science Minister Amanda Solloway said:

This investment will help UK space businesses fast-track innovative technologies with real scientific and commercial potential, supporting our aim for the UK to secure 10 percent of the global space market by 2030.

From observing climate change from space to protecting our satellites from hazardous space debris, these technologies could expand our reach in space and improve life here on Earth.

Since launching in 2011, NSTP has supported 300 projects. Previous successful applicants include Belstead Research Ltd, who improved drag sail methods for removing space debris, and a collaboration between the University of Bristol and Rutherford Appleton Laboratory to track and analyse volcanic ash clouds, which can damage jet engines.

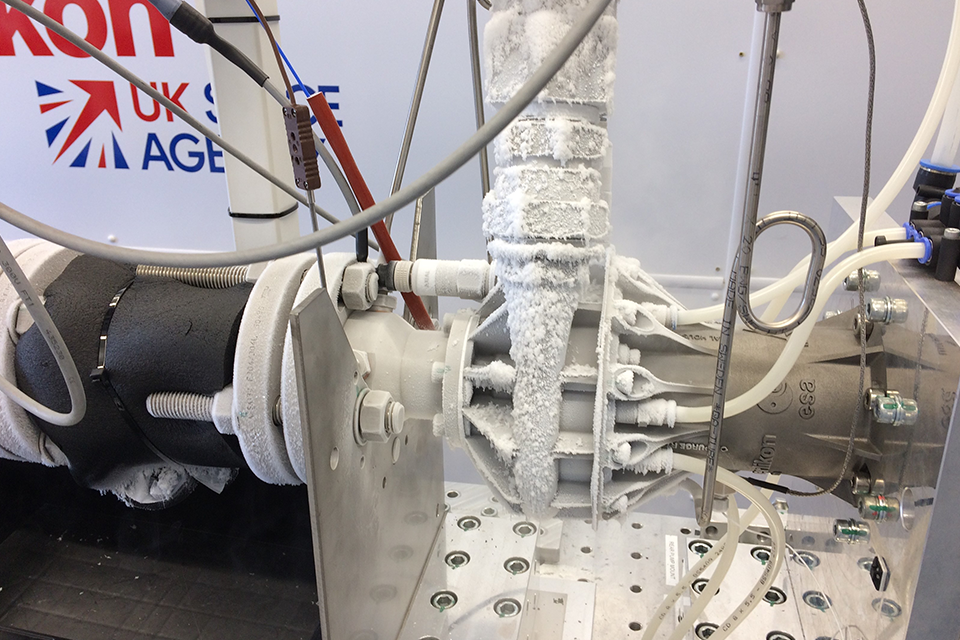

Cryogenic testing of additive manufactured propellant pump. Credit: LENA Space

Charles McCausland, Head of Major Projects and Technology Development, UK Space Agency, said:

The UK Space Agency has a strong track record of backing early-stage technologies with future potential, and these five projects promise to pave the way for further space innovation.

As the UK extends its ambitions for the space sector, early support of this kind could prove decisive in helping us get ahead in an increasingly competitive global environment.

The UK has a thriving space industry that generates an income of £14.8 billion each year. The UK Space Agency works closely with industry and academia to fund new technologies, boost skills, promote growth and inspire careers in the space sector.

The announcement comes during British Science Week (5 - 14 March), a 10-day programme of thousands of events running throughout the whole of the UK with the aim of celebrating science, engineering, technology and maths, coordinated by the British Science Association and funded by the UK Research and Innovation (UKRI).

Further details on the projects

LENA Space, Modular Propulsion Engine (MPE) Design Programme, £74,080

LENA Space, a small company based near Salisbury, is developing a rocket engine for launch vehicles. Called the Modular Propulsion Engine (MPE), the overall development plan is for an off-the-shelf, flight qualified propulsion system to support small launch vehicle programmes. The Pathfinder project will involve detailed design work on the MPE, particularly integrating several previously developed LENA subsystems - including pintle injector, electric drive cryogenic pumps and AM manufactured nozzles - into a single engine.

The University of Leeds, Advanced manufacturing techniques for supra-terahertz optical components, £74,969

Important gases in our atmosphere, and the clouds between stars are only visible in the terahertz (far-infrared) part of the spectrum — observing them is key to understanding how planets form, and how our climate is changing. Researchers at the University of Leeds and Rutherford–Appleton Laboratories are developing new ways to manufacture specialised terahertz components. They will develop liquid-crystal technology, similar to that in television screens, to produce smart lenses and shutters, and 3D-printing methods to produce ultra-thin lenses and light-filters. This will underpin the first terahertz sensors suitable for use in satellites or compact lab-based instruments.

Archer Technicoat Ltd (ATL), Nb-alloy Additive Manufacture and Iridium coating (NbAMIC), £72,778

This project aims to develop new spacecraft propulsion technologies that reduce costs and increase current methods’ efficiency. The Oxfordshire-based company will minimise material wastage and increase temperature capabilities by combining 3D-printing, special coating techniques, and an innovative material combination to improve current industry standards in thrust chamber technology. This project is the next step in creating a scalable family of efficiently priced bi- and green-propellant thrusters.

Project is being led by Archer Technicoat Ltd (ATL) with Birmingham University’s AMPLab as project partners.

Rocket Engineering, SuperMagdrive, £64,200

By using new materials and cooling systems, SuperMagdrive, which is the size of a can of coffee, will increase magnetic field density, allowing spacecraft to manoeuvre more efficiently in orbit. The compact propulsion system is designed for nano and small satellites and aims to target spacecraft customers interested in space debris mitigation and on-orbit spacecraft servicing.

Magdrive is partnered with Rocket Engineering Limited (providing systems engineering and project management expertise) and is supported by Oxford University’s Department of Materials.

Spottitt, Remote Monitoring of UK Waste & Mineral Sites, £50,296

The Oxfordshire-based project will explore the technical and commercial viability of a low cost, fully automated monitoring service for waste and mineral sites using satellite imagery. Current processes rely almost entirely on physical site visits to monitor activity and changes. Satellite monitoring offers a more cost-effective and accurate alternative which can ensure activities are more frequently monitored, thus reducing the risk of long-term environmental damage. The project will first monitor waste and mineral sites in the UK with a look to ultimately roll out the system globally.

The project is being delivered by a small but experienced team from Spottitt Ltd. in collaboration with partners Oxfordshire County Council.