Sellafield construction project brings in new digital experience

One of our largest major projects is successfully using digital modelling to accelerate project delivery.

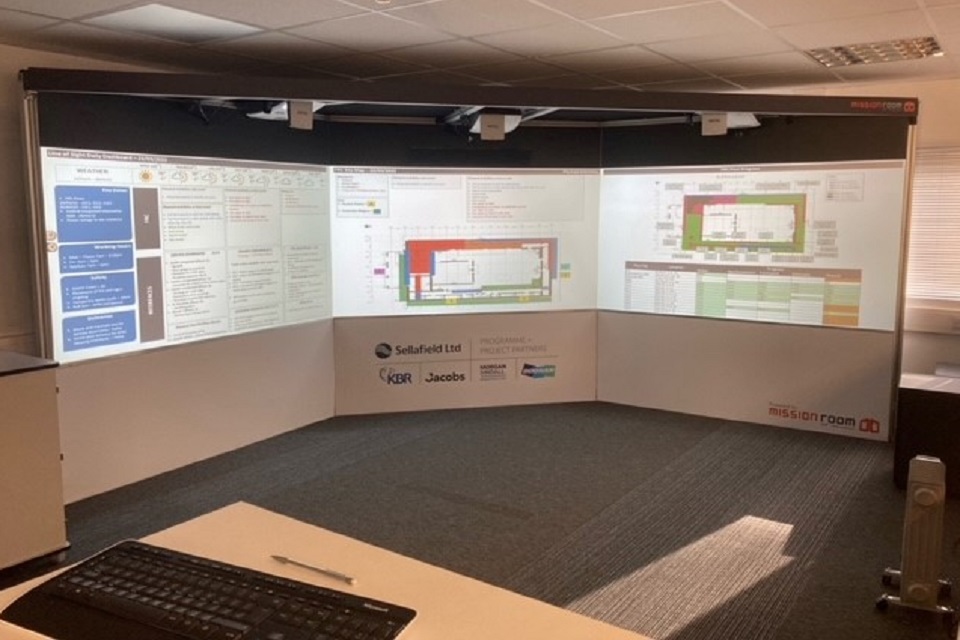

The ‘BIM cave’ in the project’s open plan office area.

The construction site for our Sellafield Product and Residue Store Retreatment Plant (SRP) has brought in an immersive digital experience called BIM – which stands for Building Information Modelling.

BIM has been used on our projects for a while now, creating interactive 3D plans to guide construction work. The new system provides a ‘BIM cave’ in the project’s open plan office area.

The “cave” provides an interactive touchscreen and immersive experience and it’s already been used to enhance work on the Sellafield site.

In a first for Sellafield, the room is on the construction site for the new facility, allowing easy access for the construction team and allowing them to get inside the plans for the building and check them for potential problems.

This means that when work starts, they can be more sure than ever that there won’t be any hold-ups and resolve issues in advance.

Steve Harnwell, head of Sellafield Product and Residue Store Retreatment plant, Sellafield Ltd said:

The BIM cave allows 3D modelling and 4D planning to be executed ‘live’ on the site and enhances the project’s daily ‘line of sight’ planning by allowing people to visualise the plan and interfaces.

This leading step is already resolving interface clashes and provides a better understanding for our workforce and supply chain. This is another advancement for deployment of BIM on Sellafield projects.

Louis Twentyman is an engineering intern currently working on the SRP project and for the past few weeks he’s been using this newest piece of tech.

Louis said:

The BIM cave allows us to interrogate the design and look for potential conflicts, safety issues and scope review. It’s also a great visualisation tool for the team on site, as we can now work with them to catch issues with the design and show it on a larger scale rather than a single computer screen.

It’s early days for the room itself but the BIM model has allowed us to bring forward the construction of the services building by at least 10 months already.

The room should allow us to avoid additional cost and delays by basically seeing into the future before it happens, to catch potential clashes and safety issues as well as develop new systems to complete the work.

Hopefully the ideas we have planned will allow us to save more time and costs.

It’s had an enthusiastic reception and lots of ideas put forward on how to use it, we’re excited for what the future holds.

More information on the Sellafield Product and Residue Store Retreatment Plant