Successful start for Sellafield repackaging mission

One of the most important risk reduction tasks in the UK nuclear industry has achieved its first milestone.

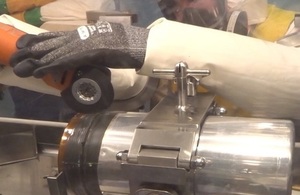

An operator working with a sealed glovebox while wearing several layers of protective gloves.

Experts at Sellafield have opened and repacked a historic plutonium can for the first time.

The work is part of a £1 billion programme to address an identified degradation risk in a small proportion of the canisters, which date from about 50 years ago.

It’s painstaking and highly skilled work which requires operators to deftly manoeuvre the package inside a sealed glovebox.

The material was originally placed in an inner can which was wrapped in a plastic casing and then placed into an ‘overpack’ can – like a Russian doll.

But in a small proportion of the packages, the outer can has shown sign of degradation.

The operators’ task is to take the plastic-coated can out of the ‘overpack’, clean off as much plastic as possible and then reseal it in a modern and more robust outer can.

This is done in a sealed glovebox while the operator wears several layers of protective gloves.

Successful start for Sellafield repackaging mission

James Millington, head of special nuclear materials at Sellafield Ltd, said:

Our teams have practised and practised the techniques using mock-up gloveboxes, so I’m delighted to see that all the preparation has paid off.

Safely getting the first package into the new outer can represents one of the most significant risk reduction milestones we’ve delivered in recent years.

Completion of the first successful repackaging kicks off a 5 year work programme.

In parallel, a new purpose-built repackaging plant is under construction which is scheduled to begin operations in the 2020s.

This will enhance the repackaging process by removing impurities in the plutonium which contribute to the degrading process.