Tech “brings the site home”

Finding solutions to put projects back on track has been helped by engaging with our partners and supply chain.

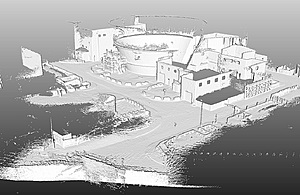

The scanned image of the reactor site

When it comes to decommissioning our legacy facilities, having the right information is vital. We have drawings and data sheets, but often these are out of date and could be misleading.

Site walk-arounds and up-to-date measurements are vital, but what if you can’t access the site you’re working on?

That was the problem facing the team working on our iconic “golf ball” facility, the Windscale Advanced Gas-cooled Reactor.

They were due to have just such a walk-around at the end of March, but had to cancel it when the nationwide lockdown hit. With the team needing accurate information to work from home, they hit on a novel solution to getting it.

A full scanning team couldn’t gain access to the site, but there were people going in for routine maintenance. The question was – could they do the work and get the detail needed?

And the answer was – yes, with partners from our Decommissioning Delivery Partnership (DDP) coming together to develop a solution.

Darren Grears from Atkins Global explained:

We decided to capture data using 2 devices – a handheld laser scanner and a 360-degree camera.

The scanner can get information up to about 10mm accuracy and is capable of scanning a 3 storey car park in less than 30 minutes. The camera can capture images to simulate a walk-around.

Working with specially-developed user guides, a maintenance team completed the scans and video during an inspection in March, taking 116 images and performing 2 laser scans of the entire building in under 2 hours.

The scans and footage gathered will now be used to guide the removal, cleaning and painting of cladding from the building, which will extend its life and ensure it is safe.

Darren added:

This is about ‘bringing the site home’. Before we can do any work, we need to identify the location of services and assets, look at potential areas for the temporary work enclosure, determine distances between adjacent buildings, scope out space for crane access and generally make sure the access is sufficient.

This will all feed into the concept design for the project and the type of temporary works enclosure required.

DDP Programme Manager Simon Martin said:

This has been a great example of people coming together to find a solution in a time of change and uncertainty. By engaging with our partners in the supply chain we were able to find a solution which has put the project back on track.