Tungsten x-ray breakthrough advances fusion roadmap

A new paper reveals how tungsten components have now been successfully scanned with x-rays to help detect defects and accurately judge its lifespan.

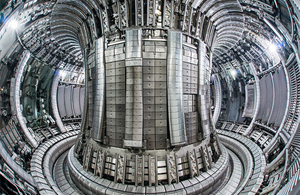

JET, the world's largest fusion energy machine. Based on the same process that powers our sun and the stars, fusion has long been considered the ultimate energy source.

Tungsten is the strongest of any natural metal. Only diamonds can lay a scratch on its surface.

It is extremely durable and can manage intense conditions. This unique quality makes it the perfect material to line the inside of a fusion energy machine, where temperatures reach 10 times hotter than the core of the sun. That is 150 million degrees Celsius, and the hottest place in our solar system.

Despite tungsten’s durability, withstanding such an intense in-vessel neutron bombardment from the fusion process could eventually compromise reliability and lead to wear out, especially in future powerplants operating around the clock. Until now, engineers and scientists had no dependable way of detecting potential structural damage – normal 3D x-ray scans are unable to penetrate due to tungsten’s incredible density.

However, a new paper published by scientists from the UK Atomic Energy Authority (UKAEA) reveals for the first time how tungsten components have now been successfully scanned with x-rays to help detect defects and accurately judge its lifespan.

This is a major step forward on fusion’s roadmap to commercial power, because structural analysis and longevity is a significant hurdle to delivering this form of safe, sustainable, low carbon energy for humanity.

Heather Lewtas, UKAEA’s Head of Innovation and co-author of the paper ‘Are tungsten-based fusion components truly invisible to x-ray inspection?,’ explains the significance of their research carried out in Culham, Oxford.

She said: “Fusion promises to be a safe, low carbon and sustainable part of the world’s future energy supply. Its predictability is one of its main strengths, but it is therefore crucial that powerplants are not taken out of service for unnecessary maintenance.

“This breakthrough study gives us confidence we will be able to assess the condition of our large and small tungsten components, which have to repeatedly withstand some of the most challenging conditions on the planet.

“The insight will allow us to assess the lifespan of our inner-vessel wall and reduce future powerplant downtime to a minimum. It is a major step forward and we are extremely proud to demonstrate this technology for the first time.”

The tungsten x-ray pilot study was led by scientist Triestino Minniti and completed under the UKAEA Fusion Technology Facilities programme, using emerging techniques.

Putting fusion electricity on the grid economically and reliably requires technological solutions to several challenges. UKAEA is undertaking cutting edge research in each category of innovation through its world-leading facilities.

Heather adds: “It is clear we must make significant changes to address the effects of climate change, and fusion offers so much potential. It has the potential to provide ‘baseload’ power and could help sustain net zero in the second half of the century.

“The ground-breaking research and innovation taking place in the UK is moving us closer, step-by-step, on this exciting roadmap to commercial power.”

What is fusion energy?

Based on the same process that powers our sun and the stars, fusion has long been considered the ultimate energy source. Fusion is rightfully difficult, but here are the basics:

When a mix of two forms of hydrogen (deuterium and tritium) are heated to extreme temperatures (10 times hotter than the core of the sun) they fuse together to create helium and release vast amounts of energy in the form of heat.

This superheated material forms a plasma, the fourth state of matter found in lightning and neon signs.

There is more than one way of achieving fusion. At UKAEA, they hold this hot plasma using strong magnets in a doughnut-shaped machine called a tokamak.

The energy created from fusion can generate electricity similar to existing power stations, namely by boiling water into steam to run a steam turbine.