Train damaged by collision with an object at Highdyke, Lincolnshire, 19 December 2023

Published 17 April 2024

1. Important safety messages

This accident demonstrates the importance of:

- persons in charge ensuring that any equipment that can affect the safety of the line has been removed from the track before it is handed back for the passage of trains

- planners, responsible managers and persons in charge ensuring that the planning of work on or near the line considers the risk associated with the equipment to be used, and that this is reflected in a safe work pack that is accurate, appropriate and specific to the task being carried out.

2. Summary of the accident

At around 06:03 hrs, a passenger train struck parts of a portable road-rail vehicle access point (RRAP) which had been left on the track at Ponton Yard, near to Highdyke, on the East Coast Main Line (ECML).

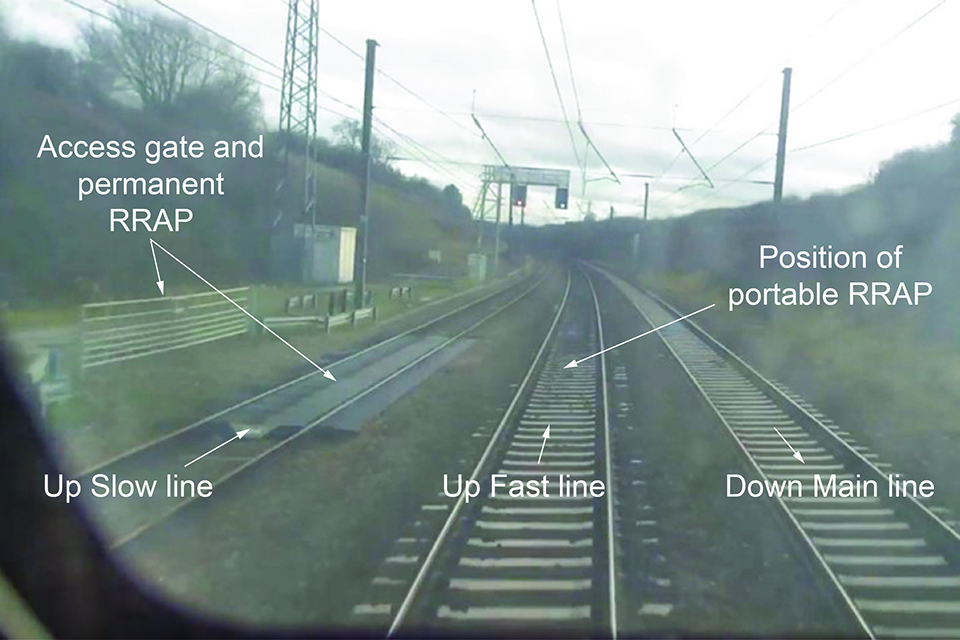

Road-rail vehicle access point at Ponton Yard near Highdyke, looking north towards Grantham.

The portable RRAP had been put in place during maintenance work that occurred the preceding night. It was used as part of an attempted on-tracking of a road-rail vehicle and was unintentionally left on the track when the line was handed back following this work.

No one was injured as a result of the collision and the train did not derail. The collision caused damage to equipment on the underside of the train, which meant that it was unable to continue its journey. The train was unavailable for service for a number of days due to repairs being required following the accident.

3. Cause of the accident

The accident occurred because a portable RRAP was unintentionally left on the track after a possession was given up, following routine inspection and maintenance of overhead line equipment (OHLE). The passage of the train disturbed light-weight parts of the portable RRAP which resulted in multiple damaging impacts to the train’s underside.

The planned inspection and maintenance was one of a number of activities in a larger track possession on the ECML south of Grantham. This was managed by a person in charge of possession (PICOP), based at Grantham North Junction (106 miles 750 yards, measured from a datum at London King’s Cross). Remotely located engineering supervisors (ES) managed two work sites within the possession. They liaised with the controllers of site safety (COSS) who were working within their respective work sites, confirming access and egress requirements to the railway via mobile phone.

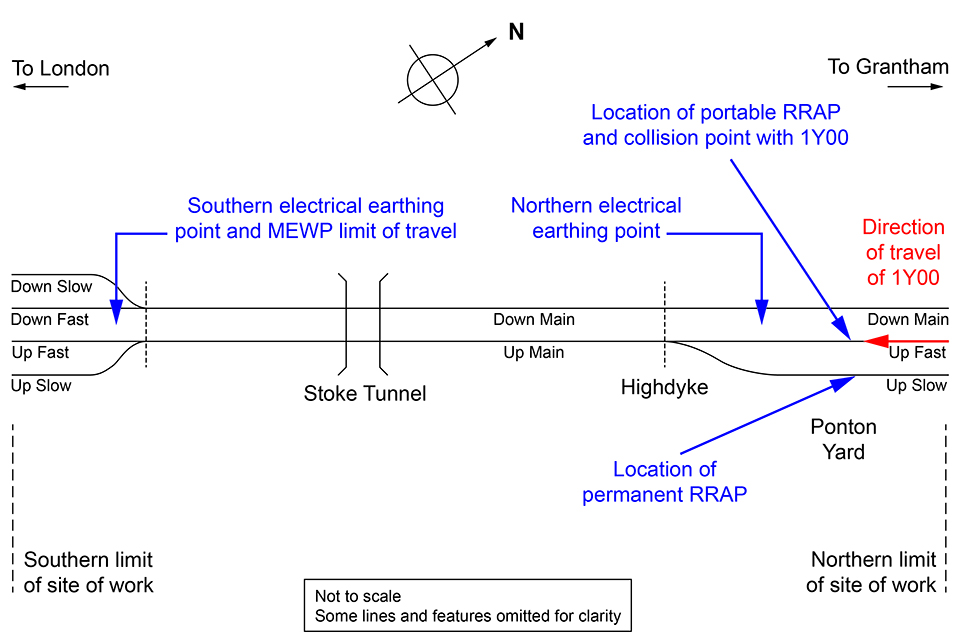

The OHLE inspection and maintenance activity was one of six sites of work within one of the work sites. This site of work had all lines blocked to service trains from south of Stoke (99 miles 550 yards), to near Grantham South Junction (102 miles 110 yards) from 01:05 hrs to 05:35 hrs.

Line map of the site of work.

The inspection and maintenance required a mobile elevated work platform (MEWP) road-rail vehicle so that the OHLE could be examined closely. The MEWP was to access the track at Ponton Yard which is within the northern part of the site of work (101 miles 75 yards).

A Network Rail road-rail vehicle with a mobile elevated work platform and basket as used on the East Coast Main Line for overhead line equipment inspections.

Ponton Yard has a track access point with a permanent RRAP located on the Up Slow line. There was no permanent RRAP on the fast and main lines where the inspection work was to be carried out. The exact method of putting the MEWP on to the track and the equipment to be used was not specified in the safe work pack, although an accompanying work plan stated that a ‘suitable RRAP/temporary RRAP/level crossing’ was to be used. On the way to the site of work, the team assigned to the task discussed the use of a portable RRAP to put the MEWP directly on to the Up Fast line instead of using the permanent RRAP on the Up Slow line. This would negate the need to move a set of points at Highdyke, approximately 500 metres to the south of Ponton Yard, to join the Up Main line.

Image captured of Ponton Yard access point from a train travelling south on the Up Fast line. From left to right can be seen the access gate, the permanent road-rail access point on the Up Slow line, the Up Fast line and the Down Main line. (Image courtesy of Network Rail.)

The portable RRAP consisted of two metal ramps that would be placed outside of the running rails and two locally modified lightweight high-density foam ramps that would be placed between the running rails. The foam ramps were created from a pre-existing commercially available kit. A wide ramp from the kit had been sawn in half to create two smaller ramps that could be spaced to better accommodate the track width of the MEWP’s road wheels.

This local modification to the foam ramp had not been approved by Network Rail nationally and its use was specific to the Network Rail Doncaster maintenance delivery unit. The MEWP would be driven over each of the ramps in turn until the centre of the vehicle was located over the two running rails. The MEWP would then use an in-built turntable to lift itself and rotate through 90 degrees to align with the direction of travel on the track.

The team carrying out the OHLE work consisted of four people. All were Network Rail employees based at the Doncaster maintenance delivery unit. They were divided into two groups. Group 1 consisted of two staff. These were team leader (PIC-1) (who was also the person in charge (PIC) of the group, the group’s COSS, and the machine controller for the MEWP), and an OHLE technician operating the MEWP (Tech-1). Group 2 also consisted of two staff. These were the PIC for the group (PIC-2), who was also the group’s COSS (and who was working under the mentorship of PIC-1), and a further OHLE technician (Tech-2).

After the team arrived at Ponton Yard, PIC-1 and PIC-2 gained permission from the ES to enter the site of work and checked that the electrical power to the OHLE was isolated. The team then separated into the two groups.

Group 2 left Ponton Yard to travel to the southern end of the site of work. There they applied an earthing strap to the OHLE. They then returned to Ponton Yard to apply a second earthing strap and tested the function of the straps. At the same time, Group 1 began the process of putting the MEWP on to the track at Ponton Yard.

After final discussion, Group 1 elected to use the portable RRAP. PIC-1 placed the four ramps forming the portable RRAP on the Up Fast line. Tech-1 drove the MEWP across the Up Slow line using the permanent RRAP, and then drove it over the installed portable RRAP and on to the Up Fast line. Once positioned over the Up Fast line, an attempt to manoeuvre the MEWP on to the tracks failed. This was due, in part, to the darkness and heavy rain present at the time.

Group 1 then decided to use the permanent RRAP on the Up Slow line instead and the MEWP was moved off the Up Fast line and successfully placed on the Up Slow line using it. The portable RRAP was left in position on the Up Fast line with the intention of it being used later in the night to remove the MEWP from the tracks.

Doncaster signal box was then contacted by PIC-1 and Highdyke points were set by the signaller to allow the MEWP to travel south beyond Ponton Yard and traverse on to the Up Main line. When Group 2 returned to Ponton Yard, PIC-2 confirmed with PIC-1 that OHLE electrical power had been isolated and was safe to approach. The MEWP then began travelling south along the Up Slow line, moving on to the Up Main line to the start point of the inspection.

While travelling, the MEWP experienced problems with its hydraulic system. When the MEWP reached the southern end of the site of work, the inspection basket (needed to inspect the OHLE) would not deploy when commanded. The team became concerned that the MEWP would become immobile and block the ECML. The inspection using the basket was therefore cancelled and Group 2 were asked to perform an OHLE inspection on foot from track level instead. The MEWP was taken back through the set of points at Highdyke and along the Up Slow line to Ponton Yard.

Once back at Ponton Yard, Group 1 removed the MEWP from the Up Slow line using the permanent RRAP. Tech-1 drove the MEWP by road back to the Doncaster delivery unit depot, with PIC-1 remaining on-site at Ponton Yard to wait for Group 2.

Group 2 completed their inspection and returned to Ponton Yard. PIC-1 secured the permanent RRAP access gates and confirmed with the ES that both groups had completed their tasks and were clear of the site of work. As stated in Network Rail standard NR/L2/OHS/019 issue 12, dated June 2023, PIC-1 was responsible for ensuring that all equipment used by Group 1 that could affect safety had been removed from the track before it was handed back for the passage of trains. Despite this, the portable RRAP which Group 1 had used remained in place on the Up Fast line.

After receiving similar confirmation from all the other sites of work within their work site, the ES in turn confirmed with the PICOP that the line was safe and clear. The possession was subsequently given up and the normal working of trains resumed.

Train 1Y00, the 05:06 hrs from Doncaster to London King’s Cross (operated by LNER), was the first train movement of the day over the site of work. Data from the on-train recorder showed that, having made a station stop at Grantham, the train was accelerating as it approached Ponton Yard and that it had reached a speed of around 92 mph (148 km/h). This was within the maximum permissible line speed for this location of 115 mph (185 km/h).

The driver in the leading vehicle did not see or hear anything as the train struck the portable RRAP. Another member of staff travelling as a passenger further along the train heard noises underneath which concerned them, and they began to make their way to the cab to warn the driver.

Remains of the portable RRAP found on track. Still in situ metal ramps (left). Displaced foam ramp (right). (Images courtesy of Network Rail.)

The high-density foam ramps damaged multiple underfloor panels along the length of the train during the collision. This included removing sections of drive motor casing, and dislodging a gearbox temperature sensor on the locomotive that was at the rear of the train. This latter damage triggered emergency braking on the train, bringing it to a halt. Train 1Y00 was subsequently recovered using a standby locomotive. The passengers were detrained at Grantham, before train 1Y00 was taken to Leeds Neville Hill depot.

PIC-1 was an experienced member of staff who held the correct competencies for the duties they were undertaking. However, on this occasion, the problems with the MEWP meant that PIC-1 was subject to distractions beyond those normally encountered during a standard OHLE inspection. These distractions may have led PIC-1 to forget that the portable RRAP remained in place on the Up Fast line when they spoke with the ES and confirmed that the line was safe for trains.

The planning process required by Network Rail for work on or near the line requires the responsible manager and planner to identify the equipment needed to complete the work and for this to be documented in the safe work pack which the PIC will then verify and implement. In this case the use of the temporary RRAP had not been considered during planning. This meant that there was no consideration about whether its use was necessary, what risks it might present, or how these could be controlled. It also meant that an accurate and complete safe work pack was not provided to PIC-1 for the inspection.

4. Previous similar occurrences

Several incidents involving railway lines being left in an unsafe condition after maintenance work have previously been identified by the RAIB.

RAIB undertook an investigation into one such event which occurred on 21 October 2021 when a passenger train travelling at 123 mph (198 km/h) struck a hand trolley on the track near Challow, Oxfordshire (RAIB report 11/2022). In this case, the checks undertaken before handing back the railway for normal operation had not identified the hand trolley’s presence. RAIB found that there were weaknesses in the process which formed part of these checks, and these were compounded by the maintenance team not following the process on the night concerned.

Other similar incidents were summarised in urgent safety advice issued by RAIB in 2018 (Urgent Safety Advice 02/2018). These incidents included:

- a collision at Cradlehall on 25 February 2018 (RAIB safety digest 05/2018), where a section of track was left over a running rail and was subsequently hit by the first train of the day

- a near miss at Kirkham on 15 May 2017 (RAIB safety digest 11/2017), where a large tubular pile had been left on the line, and was encountered by an on-track machine.