Derailment of a passenger train near Clogwyn y Gwin South foot crossing, Welsh Highland Railway, 10 June 2018

Published 25 July 2018

1. Important Safety Message

This derailment demonstrates the importance of heritage railways ensuring that specific and appropriate inspections and checks are built into the vehicle maintenance and overhaul regimes to monitor the integrity of all safety critical components which could cause derailment in the event of failure, and also to ensure that such components are reassembled correctly after overhaul. This is of particular importance on narrow gauge lines and railways that operate in mountainous areas.

2. Summary of the accident

At approximately 12:15 hrs on 10 June 2018, a passenger train, travelling from Porthmadog to Caernarfon on the Welsh Highland Railway, became derailed close to Clogwyn y Gwin South footpath crossing. The crossing is approximately 0.75 miles (1.2 km) north of Rhyd Ddu station.

The train was travelling at around the maximum permitted speed at this location of 10 mph (16 km/h). The leading wheelset of the locomotive derailed on a right-hand curve. The driver immediately applied the train’s brake and the train came to a stop in a distance of about 30 metres.

The train was hauled by a ‘Garratt’ steam locomotive, number 143, and comprised nine coaches. There were 74 passengers and 7 members of staff on board the train.

Locomotive 143 at Rhyd Ddu station travelling in same direction (right to left of photograph) as at the time of derailment

No injuries were reported amongst the passengers or crew. Due to the inaccessible nature of the location, the coaches of the train (which had not derailed) were recovered from the location by a second locomotive after a delay of approximately two hours.

Minor damage was caused to the track at the site of the accident. The locomotive also suffered some damage, and was removed from site later on 10 June 2018.

3. Cause of the derailment

The accident occurred as a result of the failure of a suspension component on locomotive 143, resulting in the complete unloading of the left leading wheel.

The derailed leading wheelset. The leaf spring suspension and associated components had become disarranged as a consequence of the failure (photograph courtesy of Ffestiniog and Welsh Highland Railways).

The undamaged opposite side of the leading wheelset on locomotive 143, taken after the locomotive had been recovered from the derailment site, showing the normal suspension arrangement. The undamaged equalising beam is arrowed.

The component which failed was a hook which formed the end of a suspension equalising beam. This type of locomotive is fitted with equalising beams on each side which connect the springs on each wheelset. Such beams are designed to ensure that the weight carried by each wheelset in response to track irregularities is evenly distributed between a locomotive’s wheels, as far as possible. The equalising beams are connected to each leaf spring by means of spring hangers.

The equalising beam with the detached hook end

The hook that failed had connected the equalising beam to a spring hanger. The spring hanger is connected to the leaf spring and transfers vertical load to the leading wheelset. There is one set of such suspension equipment on each side of the wheelset.

When the hook failed, the leading left wheel lost vertical load. Because the train was traversing a right-hand curve at the time, the loss of vertical load allowed the flange of the left wheel to climb onto and across the left-hand rail into derailment.

A visual examination of the failed component showed the presence of ‘beach’ marks on the fracture faces. These visible marks indicate progressive crack growth through a fatigue mechanism as a result of cyclic loads. The marks represent successive positions of the advancing crack front. A crack had grown until the remaining cross section of the hook was no longer able to carry the loading on it, at which point brittle fracture occurred. Although there is no means of knowing exactly when the cracking started, the ‘beach’ marks and the contamination of the fracture surface by oil and grease indicated that the crack could have been growing for a considerable period of time, possibly back to the last overhaul or even earlier.

The locomotive is subject to daily visual checks by the crew, and periodic examinations by workshop staff. However, the configuration of the hook and the spring hangers is such that it is difficult to observe any incipient cracks growing in situ.

The locomotive was subject to a full overhaul during 2015 when the equalising beams were examined. WHR believes that the failed component may have been subject to non-destructive testing during this overhaul, but there are no records of this. WHR has reported to RAIB that it was not aware of a pre-existing crack or any previous similar failures.

Examination of the locomotive post-derailment also found that two suspension components had been erroneously interchanged during the re-assembly of the locomotive during the 2015 overhaul.

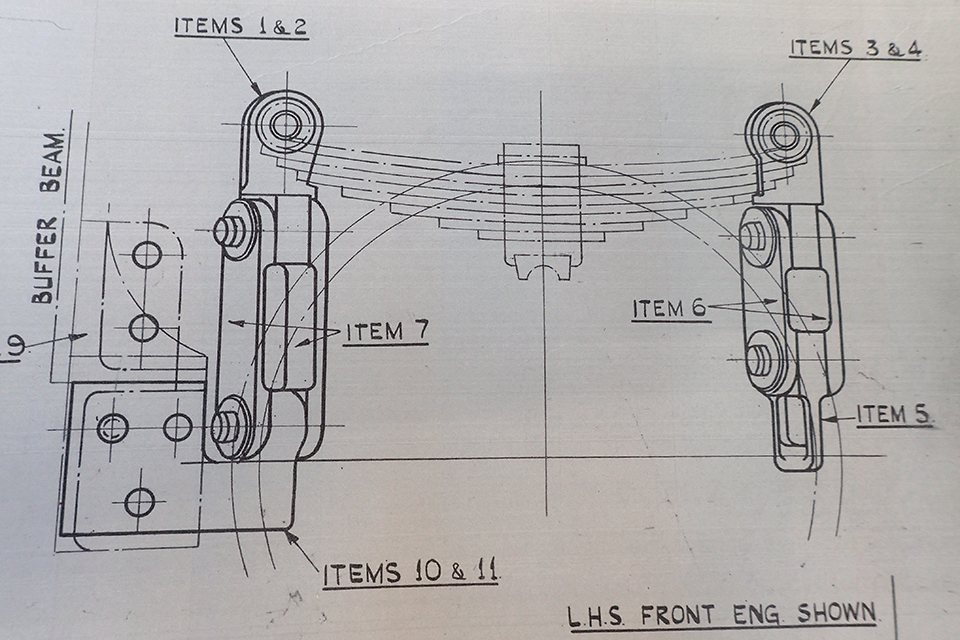

Extract from a drawing of the locomotive leading wheel suspension arrangement. The equalising beam which failed is not shown; the equalising beam hook engages with item 5 in the drawing (drawing courtesy of the Ffestiniog and Welsh Highland Railway)

The locomotive left side (in the direction of travel at the time of the derailment) assembly uses items 1 and 3, as shown in the above drawing (items 2 and 4 are mirror images, and used on the right side of the locomotive). The hole accommodating the pin which secures items 1 and 3 to the drop links (items 6 and 7) is at different angle on item 1 compared to item 3. Locomotive 143 was found, during post-derailment examination, to have items 1 and 3 transposed at the location of the failure. The effect of this incorrect assembly would have been to impart additional loading to the end of the equalising beam in the area which failed. This may have contributed to the failure.

Although this derailment had relatively minor consequences, there are many areas on the Welsh Highland Railway where the railway operates close to steep embankments. In slightly different circumstances a similar derailment could lead to a significantly more serious outcome.

You can print this safety digest.