Collision between a train and an object left on the track at Kings Langley, Hertfordshire, 25 April 2024

Published 24 July 2024

1. Important safety messages

This accident demonstrates the importance of:

- persons in charge (PICs) ensuring that any equipment that can affect the safety of the line has been removed from the track before it is handed back for the passage of trains

- planners, responsible managers and PICs ensuring that the planning of work on or near the line considers the risks associated with the equipment to be used, and that this is reflected in planning documents describing measures to mitigate such risks

- employers ensuring that workers are competent to use the required equipment

- equipment only being used in accordance with the manufacturer’s instructions or relevant standard operating procedures.

2. Summary of the accident

At around 06:43 hrs on 25 April 2024, a train travelling between Wolverhampton and London struck part of a temporary road-rail vehicle access point (RRAP) which had been left on the track near to Kings Langley on the West Coast Main Line (WCML). The temporary RRAP had been used during the previous night as part of work on overhead line equipment (OHLE).

Track ballast and debris from this collision struck a second train which was travelling in the opposite direction on an adjacent line. Ballast and debris also landed on the platforms at Kings Langley station, which were at that time unoccupied.

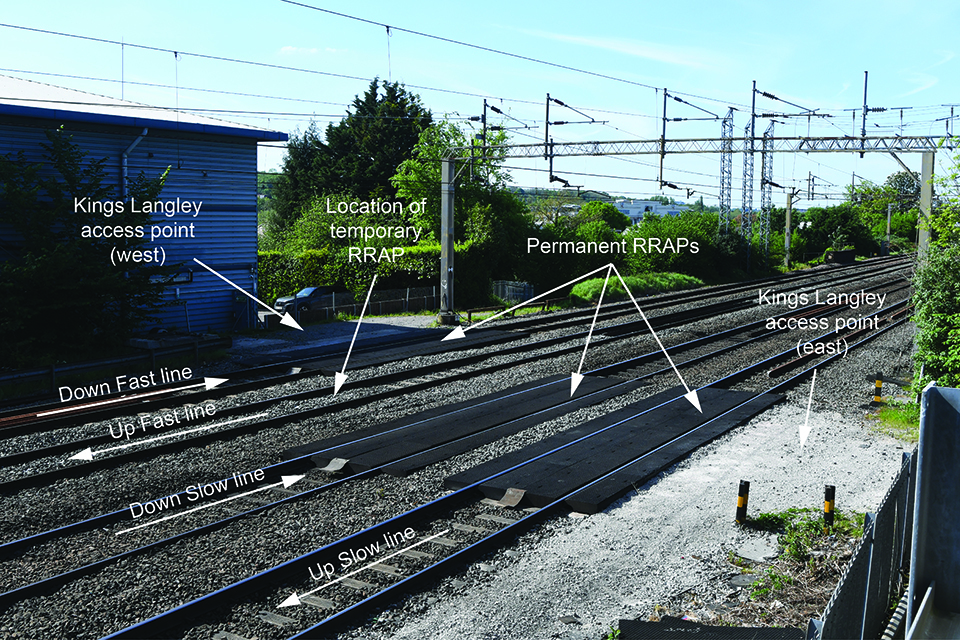

Location of the collision near Kings Langley access point, looking south towards the station.

No one was injured as a result of the collision and neither train derailed. The damage caused to both trains meant they were unable to continue in service.

3. Cause of the accident

The accident occurred because part of a temporary RRAP was unintentionally left on the track after an engineering possession was given up. This became lodged under a passing train, displacing ballast and causing a brake pad to come loose. The brake pad and ballast hit another train passing in the opposite direction, with some debris landing on Kings Langley station platform.

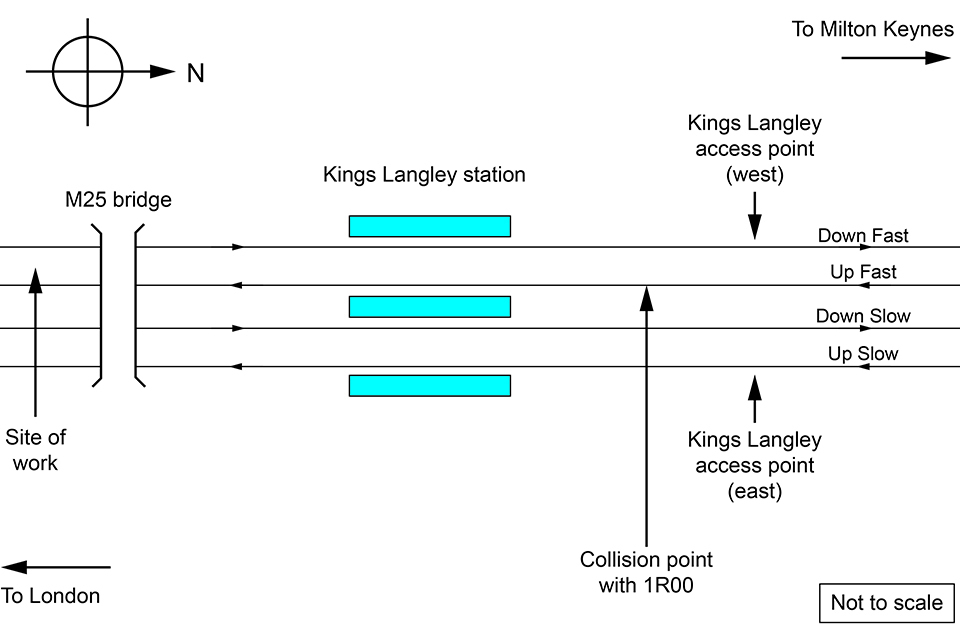

The OHLE work at Kings Langley was done within a planned possession (meaning the lines were blocked to the passage of trains) on the WCML. This possession was around 20 miles long, from Willesden North Junction (15 miles 352 yards south of Kings Langley) to Bourne End Junction (4 miles 1012 yards to the north of Kings Langley). The possession was managed by a person in charge of possession (PICOP), based at the former Watford Junction signal box. A mobile engineering supervisor (ES) managed the relevant work site in the possession, liaising with controllers of site safety (COSS) who were working within their respective sites of work.

The Down and Up Fast lines at Kings Langley were under possession between 22:30 hrs on 24 April to 06:00 hrs on 25 April. Additional protection was to be provided by a possession of the Down Slow line from 00:45 hrs to 05:20 hrs on 25 April. No work was to take place on the Down Slow line, but the blockage of that line would give road-rail vehicles additional room to manoeuvre when on-tracking onto the adjacent Up Fast line. The Up Slow line remained open throughout, with a site warden being appointed to prevent track workers getting too close to the open line.

Line map of the access point and site of work.

The rectification work needed the use of two road-rail vehicles known as mobile elevated work platforms (MEWPs) which were required to operate side by side. The MEWPs were to access the track at Kings Langley access point at the northern end of the site of work. This access point has access gates on the both the eastern and western sides of the railway. On this occasion, only the western access gate was useable due to the Up Slow line remaining open throughout the possession.

A pair of road-rail vehicles with mobile elevated work platforms as used on the WCML for OHLE equipment work.

Kings Langley access point has a permanent RRAP on three of the four running lines. The permanent RRAP from the Up Fast line had been previously removed and stored near to the eastern access gate. The first MEWP was to be on-tracked using the permanent RRAP on the Down Fast line, accessed from the western gate. The second MEWP was to be on-tracked on the Up Fast line, which was also accessed from the western gate. The ‘on track plant’ work plan identified the missing RRAP and stated that a temporary RRAP was to be installed on the Up Fast line. The plan did not specify what type of temporary RRAP was to be used, how it was to be used, any restrictions which would apply to its use, or identify any risks associated with its use.

Kings Langley access point from the eastern access side.

The temporary RRAP used consisted of four separate kits. Each kit contained five pieces made of a high-density foam material (two ramp pieces, which were to be placed outside of the running rails, with a further three pieces placed between the running rails). Each kit provides approximately 2 metres of usable RRAP length, totalling 8 metres with all four kits placed end-to-end. The maximum weight of each piece of the kit is 25 kg and they are manually lifted into place by two workers. The RRAP must be installed on track where the ballast is below the level of the sleepers. No training or guidance was provided to the staff involved as to how to install the kits.

High density foam temporary RRAP kit installation demonstration (courtesy of VP plc).

The team carrying out the OHLE work consisted of 11 people (including the site warden). They were a mix of Network Rail employees based at the Stonebridge maintenance delivery unit and contracting staff who were well known to the Network Rail staff. The team was led by an experienced member of staff who was acting as the person in charge (PIC) and therefore responsible for all aspects of safety on site (including acting as the COSS for the team). Each MEWP had an associated machine operator and a machine controller. Four team members were assigned to work from the MEWP baskets and a maintenance-manager-in-charge tracked progress of the work.

The team initially assembled at the car park near the access point on the eastern side of the tracks. Once authority to start work was given by the ES to the PIC at 23:39 hrs on 24 April, the team moved around to the access point on the western side of the tracks to access the fast lines.

As the Down Slow line was not blocked at this time, there was not enough room for a MEWP to be safely on-tracked to the Up Fast line. However, the MEWP for the Down Fast line could be on-tracked using the permanent RRAP, and this was the first task undertaken. Workers not involved in the on-tracking of the first MEWP onto the Down Fast line assisted with moving and installing the 20 pieces of the four temporary RRAP kits on to the Up Fast line for later use. The kits had previously been delivered to the access point on the western side of the tracks.

The team had trouble installing the temporary RRAP due to the high level of ballast present on the Up Fast line, which was outside the RRAP manufacturer’s installation guidelines. The team’s only available method of moving the ballast was by using their hands and feet, as no shovels or similar tools were available. As a result, it is probable that the temporary RRAP was installed sitting higher than was allowable, meaning there was insufficient clearance from the underside of any MEWP passing over it.

Confirmation of the possession of the Down Slow line was given by the ES to the PIC at 01:16 hrs on 25 April. The second MEWP then crossed the Down Fast line using the permanent RRAP and was on-tracked on the Up Fast line using the temporary RRAP.

With the two MEWPs now on-tracked onto the Up and Down Fast lines, they travelled together to the site of the OHLE work, approximately one mile to the south of the access point. Closed-circuit television (CCTV) from one of the trains involved in the later collision shows a piece of the temporary RRAP located approximately 40 metres to the south of the location where the RRAP had been installed. This was likely a result of the MEWP on the Up Fast line disturbing the incorrectly installed temporary RRAP and dragging the piece away from the access point as it travelled south. This was not noticed by the workers in either MEWP. A later reconstruction demonstrated that a MEWP of the type involved in the work could drag a piece of RRAP that is sat on ballast above the sleeper level in this manner.

After the OHLE work was complete, the two MEWPs returned north to the Kings Langley access point at approximately 03:00 hrs. The MEWP on the Down Fast line off-tracked using the permanent RRAP and left via the western access point. The MEWP on the Up Fast line derailed on the temporary RRAP while it was being off-tracked, probably due to its earlier incorrect installation. After the MEWP was inspected and confirmed to be undamaged, the machine controller moved sections of the disturbed temporary RRAP around to facilitate its re-railing. Once this was complete, the MEWP was off-tracked and removed from site.

The remaining workers removed the pieces of the temporary RRAP that could be seen in the darkness using head torches. These were loaded onto a flatbed lorry and taken away from the site. The PIC completed a check of the access point for equipment but did not notice the displaced part of the temporary RRAP around 40 metres away, which remained on the Up Fast line. No component counts or other checks were undertaken to ensure that all 20 pieces of the RRAP were accounted for and had been removed from the railway.

Network Rail standard NR/L2/OHS/019, ‘Safety of people at work on or near the line’, issue 12 dated June 2023, makes the PIC responsible for confirming that all equipment used that could affect safety has been removed from the track before it is handed back for the passage of trains. The PIC confirmed with the ES at 03:15 hrs that the group had completed their work, were clear of the site and that the line was safe for the passage for trains.

After receiving similar confirmation from all the other sites of work in the work site, the ES in turn confirmed with the PICOP that the line was safe and clear and handed back the worksite. The possession was subsequently given up and the normal working of trains was resumed.

Train 1R00, the 04:57 hrs service from Wolverhampton to London Euston, operated by Avanti West Coast, was the first movement of the day over the Up Fast line after the possession was given up. This train struck the temporary RRAP piece which remained on the Up Fast line. The train’s on-train data recorder recorded that the train was travelling at a speed of 124 mph (200 km/h) at the point of the collision. The permissible speed for this train on the Up Fast line at the location is 125 mph (201 km/h).

Forward-facing CCTV from the cab of train 1R00. The displaced piece of the temporary RRAP can be seen in between the running rails of the Up Fast line (courtesy of Avanti West Coast).

The RRAP piece became trapped under the rear of train 1R00, disturbing ballast and dislodging a brake pad. The drivers first became aware of an issue when the train’s systems indicated a loss of electrical power. Staff further along the train also reported a loud noise which was followed by the deflation of a secondary suspension airbag on the rearmost coach.

Train 9S44, the 06:16 hrs service from London Euston to Edinburgh Waverley, also operated by Avanti West Coast, was travelling at approximately 107 mph (172 km/h) when it passed train 1R00 on an adjacent line at Kings Langley station. Debris from train 1R00 impacted train 9S44, damaging its windscreen, and the latter was subsequently brought to a halt by its driver. The driver of train 9S44 made the signaller aware of what had happened. The signaller then stopped 1R00 and all other trains in the area.

Forward-facing CCTV from 9S44 as it passes 1R00 through Kings Langley station. A dust cloud and debris is evident from the rear of 1R00 (courtesy of Avanti West Coast).

Ballast and the brake pad from train 1R00 were later found on the platform of Kings Langley station. Train 9S44 was allowed to move forward to Milton Keynes Central station where its passengers were disembarked and it was removed from service. The section of the temporary RRAP was removed from under train 1R00. This train was moved forward to Watford Junction station where its passengers were disembarked and it was also removed from service.

Remains of the temporary RRAP found under train 1R00 (left) and the brake pad found on Kings Langley station platform (right) (courtesy of Network Rail).

The PIC and senior members of the track team were experienced in their roles and held the correct competencies for the duties they were undertaking. They were well informed as to their responsibilities for returning the line in a safe condition. On this occasion, the decision to use a temporary RRAP, its poor fitment to the track, poor lighting conditions and a lack of training in its correct use all contributed to the PIC (and, in turn, the ES) incorrectly confirming that the line was safe for trains.

The planning process required by Network Rail for work on or near the line requires the responsible manager and planners, with involvement of the PIC, to identify the equipment needed to complete the work. This is formally documented, which the PIC will then verify and implement on site. The ‘on track plant’ work plan used in this case did identify the need to use a temporary RRAP but did not detail the specific type to be used, nor cover any risks associated with its use.

The site where the temporary RRAP was to be used was also assessed as being suitable during the planning process. However, the high level of ballast present did not meet the RRAP manufacturer’s recommendations. The lack of training provided to the staff meant that they were not able to assess the temporary RRAP’s unsuitability for use at this site. Although issues arose during its installation, the team continued due to the time pressures of completing the OHLE work and because no alternative arrangement was available.

4. Previous similar occurrences

Several incidents involving railway lines being left in an unsafe condition after maintenance work have previously been identified by RAIB.

RAIB undertook an investigation into one such event which occurred in October 2021, when a passenger train travelling at 123 mph (198 km/h) struck a hand trolley on the track near Challow, Oxfordshire (RAIB report 11/2022). In this case, the checks undertaken before handing back the railway for normal operation had not identified the hand trolley’s presence. RAIB found that there were weaknesses in the process which formed part of these checks, and these were compounded by the maintenance team not following the process on the night concerned.

Similar incidents were summarised in urgent safety advice issued by RAIB in 2018 (Urgent Safety Advice 02/2018). These incidents included:

- A near miss at Kirkham in May 2017 (RAIB safety digest 11/2017), where a large tubular pile had been left on the line, and was encountered by an on-track machine.

- A collision at Cradlehall in February 2018 (RAIB safety digest 05/2018), where a section of rail was left over a running rail and was subsequently hit by the first train of the day.

At Highdyke in December 2023 (RAIB safety digest 02/2024), a similar incident to that at Kings Langley occurred when a temporary RRAP was left on track after OHLE work. The first train of the day collided with the temporary RRAP, causing it to be withdrawn from service. A lack of planning and the absence of any assessment of the risks of using the temporary RRAP were also features of this incident.