Derailment of a freight wagon at Carpenters Road North Junction, near Stratford in East London, 11 June 2019

Published 30 September 2019

1. Important safety messages

This accident highlights:

- the potential for a sub-optimal working environment to increase the likelihood of errors when undertaking maintenance activities

- the importance of checking that securing devices, such as split pins, are correctly fitted following maintenance, and the serious consequences which can result from not doing so

- the importance of the effective positioning of safety straps and loops intended to prevent large components falling onto the track if they become detached from vehicles

2. Summary of the accident

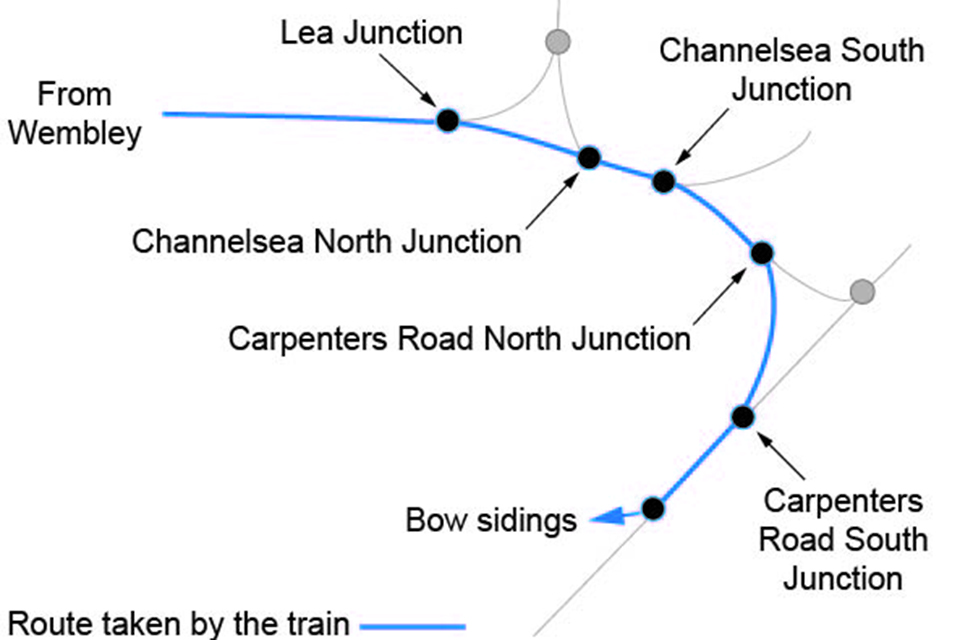

At around 19:08 hrs on 11 June 2019, an empty wagon in a freight train derailed while travelling at approximately 15 mph (24 km/h) around Carpenters Road North Junction (figure 1). It then travelled around 400 metres, causing damage to railway infrastructure, before re-railing at Carpenters Road South Junction. The wagon derailed because it ran over a substantial part of its own brake equipment which had fallen onto the track beneath it (figure 2).

Figure 1: Route taken by the train

Figure 2: Detached brake gear found after the accident (courtesy Network Rail)

The train involved consisted of a diesel-electric locomotive hauling 11 empty JNA type wagons, each comprising a box body with a two-axle bogie at each end (figure 3), and was travelling from Wembley, in north London, to Bow, in east London. It had departed from Wembley at around 18:14 hrs and, at around 19:05 hrs, was stopped by signals on the approach to Channelsea North Junction, to let a passenger train cross its path.

Figure 3: Wagon involved in the accident

Shortly after the train restarted its journey, a component of the braking system on the seventh wagon became partially detached and began bouncing along the track. Shortly after, as the wagon passed through Carpenters Road North Junction, a substantial part of the wagon’s braking system detached. This equipment fell onto the track, where a trailing wheel on the leading bogie ran over it and derailed.

The wagon ran derailed, damaging sleepers and signalling equipment, and breaking a rail, before it re-railed at Carpenters Road South Junction and continued to Bow sidings, a short distance beyond Carpenters Road South Junction. Neither the train driver, nor a manager in the driving cab, noticed anything unusual during the derailment.

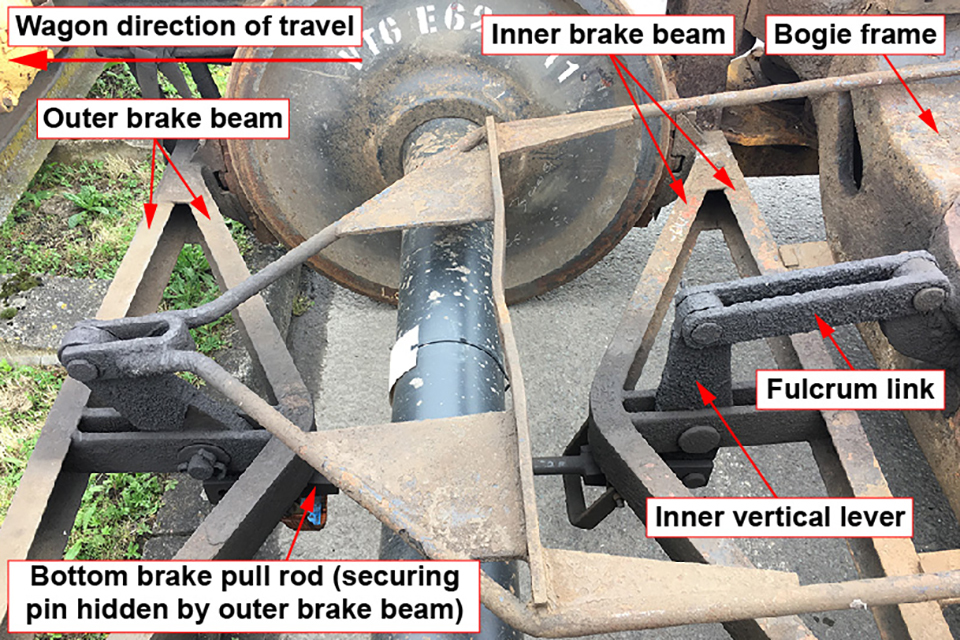

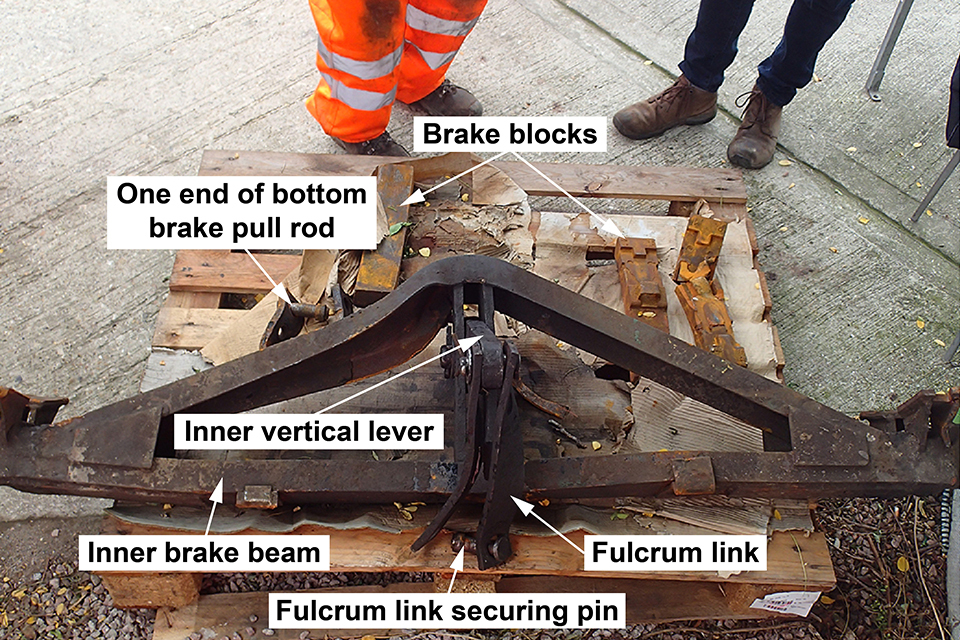

The braking system comprises a system of rods, beams, levers and links (figures 4 and 5) which are connected by securing pins and which transfer force from the brake cylinder onto brake blocks, causing them to be pulled against the wagon wheels when braking is required. Some securing pins require a split pin to be inserted at one end to prevent the securing pin falling out.

Figure 4: Wagon brake components (viewed from above a similar bogie without a wagon body)

Figure 5: Wagon brake components (viewed from below a similar bogie)

The braking components that fell from the leading bogie of the seventh wagon (figure 6) included a bottom brake pull rod, the leading wheel set inner brake beam and some associated components including brake blocks. This bottom brake pull rod had been positioned beneath the leading axle with each end connected to a brake system lever by a securing pin.

Figure 6: Detached wagon brake components

3. Cause of the accident

The most probable cause of the brake components falling from the underside of the wagon was a missing split pin in the securing pin at the leading end of the bottom brake pull rod. The securing pin then worked loose allowing the leading end of the pull rod to drop and bounce along the track until it struck switch and crossing components at Carpenters Road North Junction. This impact pushed the trailing end of the pull rod against the lever attached to the inner brake beam, causing this and associated components to break away from the bogie.

Evidence supporting this sequence of events comprises marks on the track indicative of the bottom brake pull rod bouncing on sleepers, and the deformation of components consistent with the inner end of the bottom brake pull rod exerting significant force on the inner vertical lever and fulcrum link (figure 6).

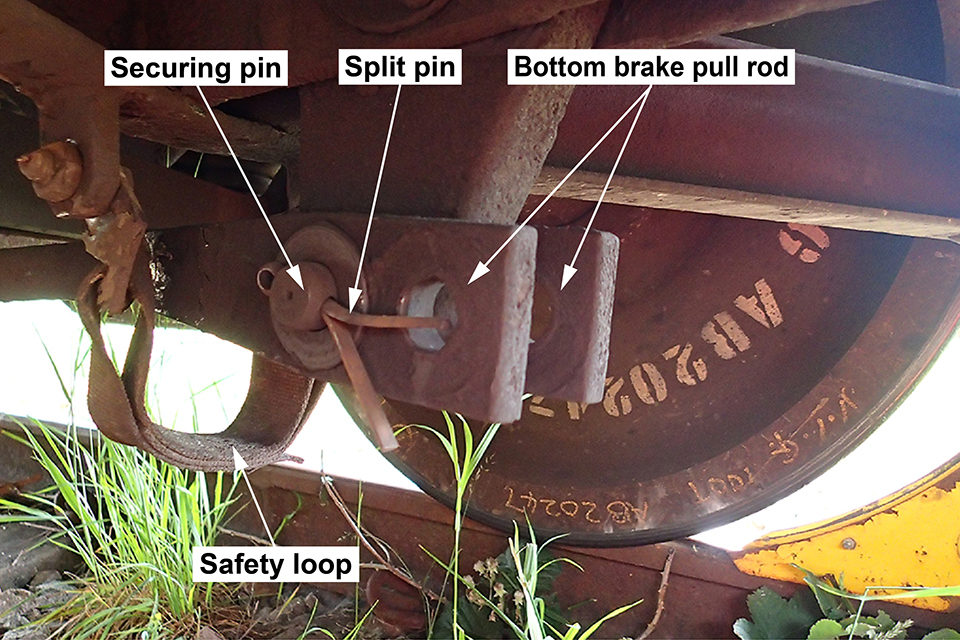

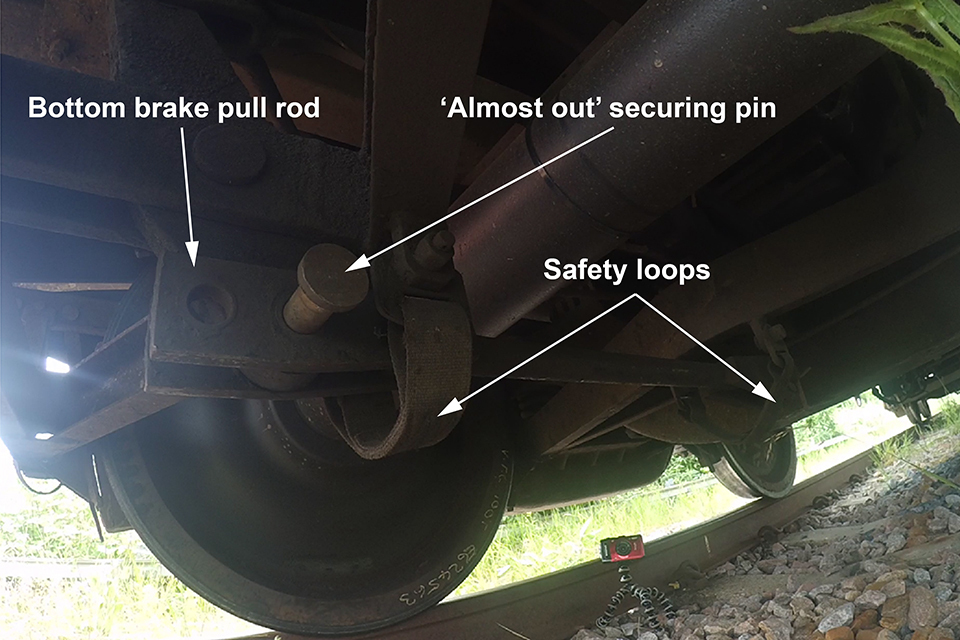

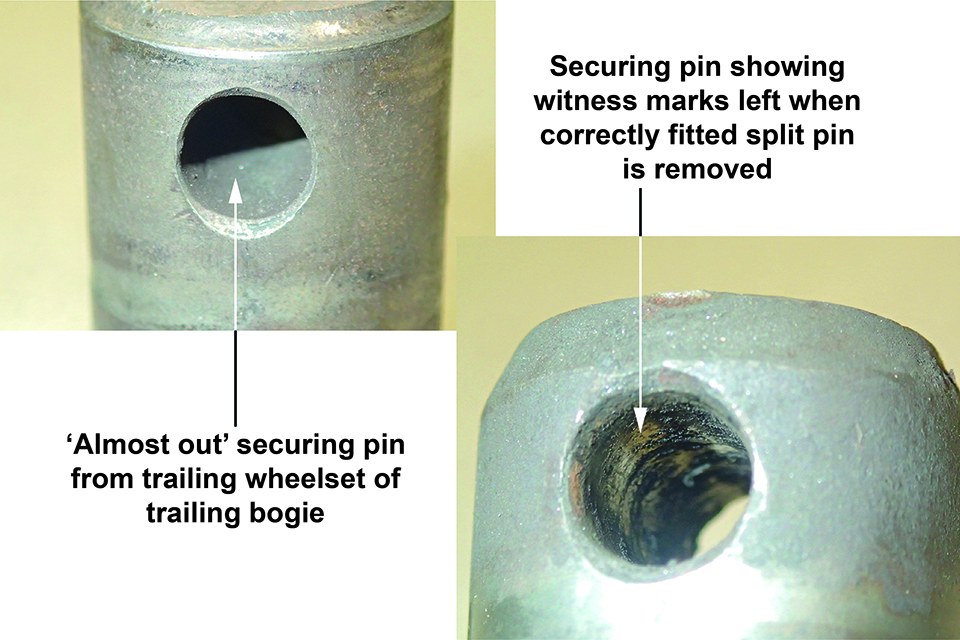

The investigation also found that the split pin was missing from the securing pin at the corresponding position on the bogie at the trailing end of the wagon, which had allowed the securing pin to almost work loose from the outer end of its bottom brake pull rod (figure 7). The absence of witness marks on the inner surface of the hole through which the split pin is inserted suggests that a split pin was never fitted or was not correctly fitted to this particular securing pin (figure 8).

Figure 7: Trailing end bogie showing pin ‘almost out’ on trailing wheelset due to missing split pin at the end furthest from camera

Figure 8: Comparison between ‘almost out’ securing pin (left image) and a securing pin that had been in service with a correctly fitted split pin (right image)

The securing pin at the leading end of the bottom brake pull rod on the leading bogie was not among the broken components found after the accident, so there is no direct evidence to confirm that this split pin was missing. However, no credible alternative sequence of events that is consistent with the evidence has been identified.

The bottom brake pull rod which fell from the wagon, and the bottom brake pull rod with the ‘almost out’ securing pin, were last disconnected from the braking system on 10 April 2019 when the associated wheelsets were replaced. New split pins should have been fitted when the brake pull rods were reconnected, but it is likely that the split pins at the two outer-ends were unintentionally omitted or not fitted correctly (figure 8).

A team of three maintainers were involved in the work on 10 April 2019. None of them could remember, and maintenance documentation does not record, who undertook the reconnection of the bottom brake pull rods and who had checked that the work had been carried out correctly. The work was carried out in a sub-optimal open air location with no pit or other arrangement to facilitate convenient access to the underside of vehicles: research published by RSSB (a not-for-profit body whose members are the companies making up the railway industry) indicates that environmental conditions such as poor lighting, and extremes of temperature or weather, can increase the likelihood of errors.

The wagon owner reports that no missing split pins were identified by a post-accident inspection of 16 similar wagons that had been maintained since January 2019 by the staff involved with the work on 10 April 2019.

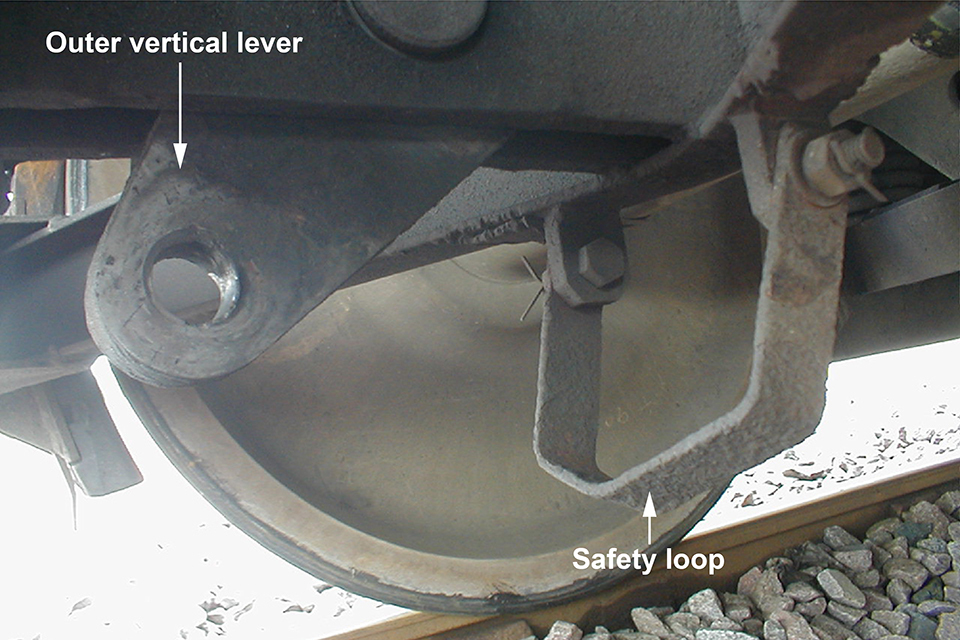

A detached bottom brake pull rod should not lead to an unsafe outcome. A safety loop is fitted underneath both ends of each bottom brake pull rod, which is intended to catch a detached pull rod and so prevent it falling onto the track (figure 7). The safety loops at the ends of the detached bottom brake pull rod show no evidence of significant contact with the detached rod. RAIB detached a bottom brake pull rod from its vertical lever at the other end of the wagon, and found it was successfully caught by the safety loop. However, when the detached rod was pushed back and forth there was sufficient travel for it to pass out of the safety loop and fall to the track. Such movement could be generated when the vehicle is in motion.

The owner of the wagon involved in the accident reported to RAIB that it is redesigning the arrangement of the safety loops to bring them closer together and so prevent a detached bottom pull rod falling past the safety loops. It is also intending to introduce a process to give an individual the responsibility for checking/inspecting the work which has been carried out either by themselves or others.

4. Previous similar occurrences

On 12 July 2001, it was reported through the GB rail industry’s ‘safety related defects on rail vehicles’ reporting system (the NIR system) that a bottom brake pull rod, fitted to the same type of wagon as that involved in this accident, had become detached and that the safety loop failed to catch it when it fell from the underside of the wagon (figure 9). Photographic evidence indicates no significant contact between the detached lower brake pull rod and the safety loop. The NIR system does not record the details of any actions that were subsequently taken by the owners of the wagon type.

Figure 9: Photograph of underside of wagon involved in July 2001 incident

On 23 February 2011, a wagon within a freight train derailed at Dalchalm level crossing, Highland, Scotland (RAIB Bulletin 03/2011). Damage was caused to the road surface at two level crossings, to the track and to signalling equipment. The wagon derailed because part of its braking system detached, fell onto the track and was run over by the wagon’s wheels. The RAIB’s examination determined that the failure of a split pin seems to have been the most likely initiating event, as it could be subject to wear just under the pin head, probably due to the degree of free movement inherent in the hanger pin assembly design.

Extensive damage was caused to railway infrastructure in 2017 by a train travelling between Ferryside and Llangennech, probably because split pins were not fitted when wagon brake blocks were replaced at an outdoor location (RAIB Report 17/2018. These missing pins were the probable cause of a catastrophic brake system failure which caused a wheelset to lock up, resulting in severe wheel flats and then, when the wheelset began to rotate again, significant damage to infrastructure. The RAIB observed that the pins were probably omitted when work was undertaken at a suboptimal outdoor location, and made a recommendation to the owner of the wagon involved, relating to improving the working environment for wagon maintenance activities at the location where the wagon’s brake blocks were changed.