Near miss between a tamper and steel pile near Kirkham, Lancashire, 15 May 2017

Published 8 August 2017

1. Important safety messages

This incident demonstrates the importance of:

- having a formal, well briefed process for checking that a site of work is clear of materials and equipment at the end of work, including identification of the person with responsibility for the checking

- where possible, not placing objects capable of endangering trains in locations where such equipment could present a threat to railway safety were they to be forgotten

- good lighting at a site of work to illuminate any materials or equipment remaining on the track at the end of work

2. Summary of the incident

At around 05:14 hrs on Monday 15 May 2017 a tamper, which was travelling to leave an engineering possession, encountered a large tubular steel pile obstructing the track near Kirkham North Junction, north-west of Preston. The driver stopped his tamper a reported 15 metres short of the pile. The pile, measuring 610 mm diameter and 5 metres long, and weighing around 1 tonne, had been left on the track on completion of earlier engineering works. The work site had however, been given up and declared safe for the passage of trains.

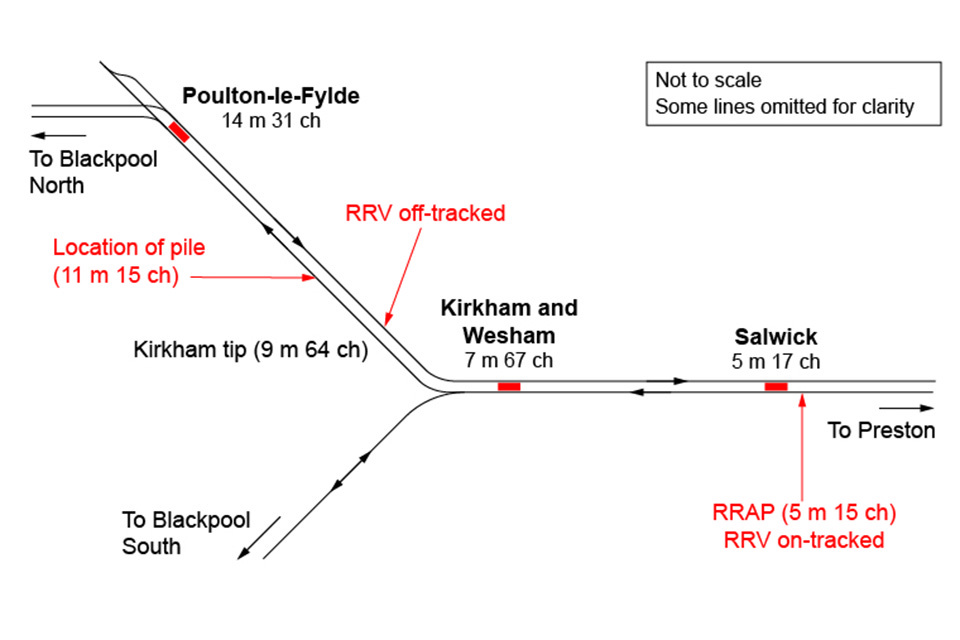

Schematic diagram showing locations of the metal pile and the road rail access points at Salwick and Kirkham tip

3. Cause of the incident

The tamper encountered the pile because it had been temporarily placed on the track earlier. No one had identified that it remained there when the track was handed back and declared safe for the passage of trains once the work was complete. The lack of a clear process for ensuring that the track was clear of obstructions was a factor, which may have been exacerbated by time pressures.

J Murphy was sub-contracted to VolkerRail to install piled foundations for structures to support overhead line equipment, as part of the electrification of the railway from Preston to Blackpool North.

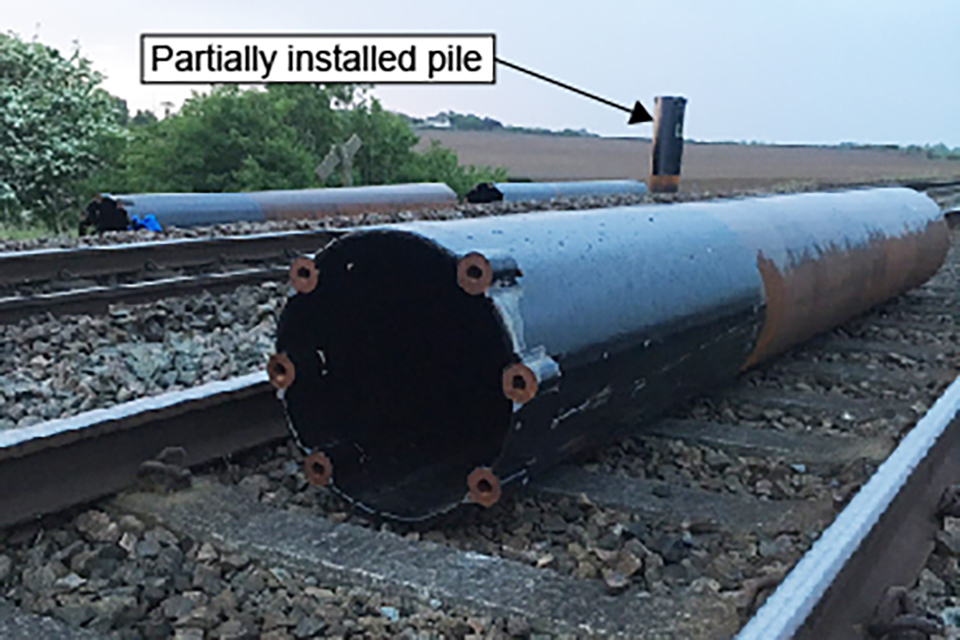

The pile lying in the four foot as found by the tamper driver (image courtesy of Network Rail). The partially installed pile is standing in the cess

On 14/15 May a planned possession of the lines from Preston Fylde Junction to Blackpool North was taken by the person in charge of the possession (PICOP) at 23:10 hrs and was due to be handed back at 06:10 hrs. The time available for piling work was restricted to allow the passage of a tamper at the start and end of the possession.

The tamper travelled from the Preston end of the possession and, once it had reached its site of work (which was beyond the area where the piling was to take place), the engineering supervisor (ES) authorised J Murphy staff to start work at 00:25 hrs. The ES required the site of work to be clear by 04:40 hrs to allow sufficient time at the end of the possession for the return passage of the tamper.

The piling work involved the use of a road-rail vehicle (RRV) fitted with a special piling attachment. Piles had already been positioned in the cess (the area between the track and the boundary fence) in readiness for installation and trial holes dug at marked locations to confirm the location of underground services.

At 01:20 hrs the RRV was on-tracked by the machine operator and crane controller at a Road Rail Access Point (RRAP) at Salwick. They then travelled 4 miles and 45 chains to the first installation site at 9 miles and 60 chains, close to Kirkham and Wesham Tip, arriving at 03:10 hrs. There they met, as planned, two other J Murphy employees, including the supervisor for the installation work.

Piling operations commenced with one pile being successfully installed. A second pile was not installed because a survey of the site revealed the unexpected presence of buried electrical cables. The team then moved to another site at 11 miles and 11 chains but were unable to install a pile at that location because the supervisor did not have the necessary information about the trial hole.

The RRV then moved around 50 metres to a third location with the pile intended for the second position still attached. The crane controller reportedly instructed the machine operator to put down the pile that was clamped in the piling attachment so that the correct pile for that location could be picked up and installed. The RRV operator drove around 20 metres beyond the installation site and put the pile down in between the rails (an area known as the ‘four foot’) of the adjacent line at approximately 11 miles and 15 chains. He then picked up the correct pile for the location and, at around 04:00 hrs, began to install it.

The installation did not go well and, with the deadline for handing back the work site approaching, work was stopped at around 04:20 hrs with the pile partially installed and deemed safe. The RRV returned to the RRAP at Kirkham and Wesham Tip and off-tracked. At 04:31 hrs the crane controller telephoned the ES to confirm that the machine was clear of the line. Meanwhile, the supervisor and colleague walked from the site of work to a nearby access point and at 04:32 hrs confirmed to the ES by telephone that the work group was clear of the track.

Sunrise began that day at 05:11 hrs with full daylight occurring at 05:15 hrs.

At 05:10 hrs the ES handed the work site back to the PICOP and signed the work site certificate as ‘Work completed, portion of line clear and safe for trains to run’.

The PICOP then authorised the tamper driver to travel to the exit of the possession at the Preston end. Approximately five minutes later and while travelling at a reported speed of 15 mph (24 km/h) the driver saw an object obstructing the line and managed to brake to a stand before colliding with it.

An emergency work site was granted and the RRV returned to the site to remove the pile. The line was reopened to normal traffic at 06:40 hrs.

The Rule Book requires that, on completion of work, those responsible for safe systems of work within possessions contact the ES to advise that the work group are clear of the line. It also requires that the ES advises the PICOP when they no longer need to be on or near the line and that they are satisfied that there are no engineering trains or on-track plant left in the work site. However, the Rule Book does not clearly specify who is responsible for physically checking that the line is clear of obstructions. Although the Work Package Plan (WPP) produced by Volker Rail for the work stated that upon completion of works ‘any plant and redundant materials should be removed from site’, it also did not specify who was responsible for this.

Better lighting of the site of work might have reduced the likelihood of the pile being forgotten. The WPP had identified risks with working at night and specified the use of tower lighting at worksites to illuminate work areas. However, the piling operation was lit only by lights on the RRV. This meant that staff were unlikely to be able to see the pile left in the four foot of the down main line when they left the site.

4. Previous similar occurrences

RAIB report 20/2016 describes a collision between a train and an excavator bucket that had been left on the line at Knockmore Junction in Northern Ireland. The RAIB recommended that the infrastructure owner introduce a process to ensure that the engineering supervisor or other designated individual(s) are assigned responsibility for carrying out a visual inspection (or implementing equivalent checks) to confirm that track within a worksite is in a safe condition after engineering activities are completed and before the worksite is given up. The assignment of responsibility should be pre-planned (where possible before work commences), documented and practical.

RAIB report 12/2015 describes an incident where a train struck the insecure doors of a location cabinet in a tunnel. It contained similar recommendations about adopting a more rigorous process for the handing back of the railway for the passage of trains after engineering works.

RAIB bulletin 03/2015 describes an incident where a train struck a wooden sleeper that had fallen onto the track from a trailer being drawn by a road rail vehicle. The RAIB identified two learning points. One was a reminder to staff who plan work involving the lifting and transporting of loads on trailers, that control measures should be specified in the authorised work plan. The second reinforced the need to clarify the responsibilities for ensuring the safety of the line at the conclusion of engineering work.

You can print this safety digest