Near miss with track workers at Dundee, 10 July 2018

Published 19 October 2018

1. Important safety messages

This incident demonstrates:

- that the processes and documentation surrounding safe system of work planning can be vulnerable to misunderstanding, particularly in areas where duplicate mileages on adjacent or nearby routes can cause confusion

- the need for the person in charge of the work activity to be actively involved in the planning process in order to minimise the chance of such misunderstandings occurring

2. Summary of the incident

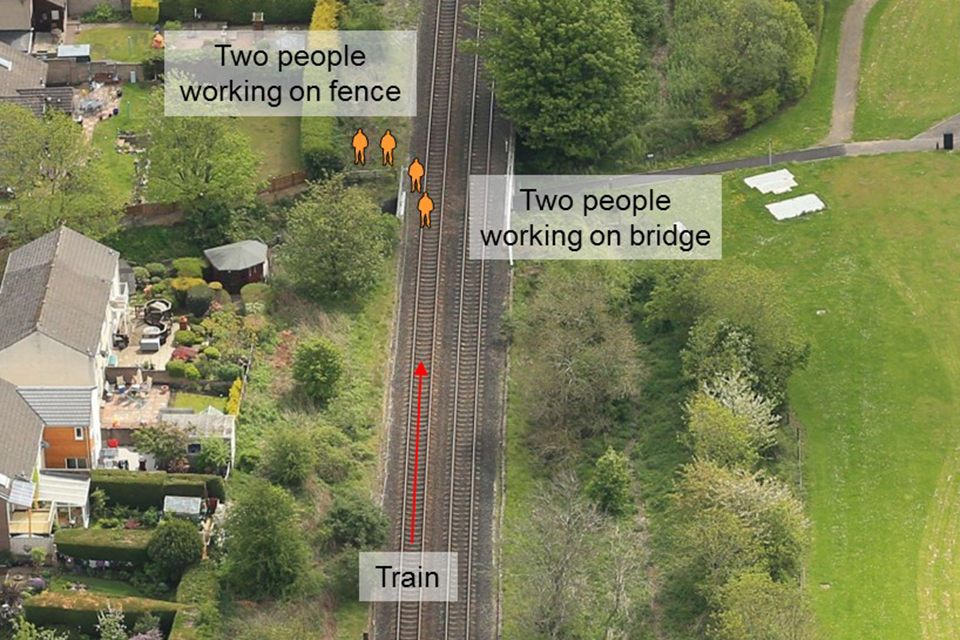

At around 00:30 hrs on Tuesday 10 July 2018, four track workers were involved in a near miss with a train about two miles west of Dundee. The track workers were working on a bridge over a footpath when the train, travelling at 72 mph (115 km/h), approached them. Two of the track workers were on the bridge at the time (the other two were working on a fence just off the railway line); one of these climbed through the bridge handrail to get clear of the train, while the other pulled himself towards the handrail, with very little space available between him and the train.

The train involved was the 22:48 hrs service from Glasgow to Dundee. On approaching the track workers, the train driver sounded the horn and made a full brake application, reducing the train’s speed to about 32 mph (51 km/h). He then reported the incident to the signaller at Longforgan.

Nobody was injured, but the train struck a portable generator being used by the track workers.

Aerial view of the location showing the bridge, the direction of the train, and the approximate locations of the four track workers at the time of the incident (adapted from an image provided by Network Rail)

3. Cause of the incident

The incident occurred due to a number of people not realising that the location of the work, and the location where protection of the work from moving trains had been planned, were different. Lines had been blocked to allow the work to be carried out, but this blockage was actually about two miles east, rather than west, of Dundee station. Crucially, railway mileages increase both to the east and west of Dundee, from zero datum points either side of Dundee station. Therefore, the mileage at the site of the work appeared to be consistent with that for the blockage; however, these mileages referred to different sections of line. This confusion arose at several points in the planning process.

The process involved several people, all of whom worked for AMCO (a construction and engineering company which had a contract with Network Rail (Scotland) to carry out minor infrastructure works). It began when a track access request was raised by a senior supervisor in AMCO’s local office. As well as details of the work itself (repairs to the ironwork of the bridge parapet), the track access request form included reference to the structure number and its location (2 miles 1232 yards from Dundee), the route that it is on (using the Engineer’s Line Reference [ELR] SCM5), and the mileage limits of the protection that would be required to complete the work (2 miles 1100 yards to 2 miles 1350 yards). This form was then given to a planner to arrange the line blockage and to prepare a safe work pack (documentation provided to the person in charge giving information on how risks associated with the work can be managed).

Map showing the location of the bridge, the location of the line blockage, and the mileage values either side of Dundee

According to witness evidence, the planner was very familiar with the railway to the east of Dundee and had worked there many times himself. This was not the case in respect of the lines west of Dundee. Seeing that the track access request referred to Dundee, he concluded that the area for which he needed to plan the line blockage was to the east of Dundee. Although the track access request referenced the ELR relating to track west of Dundee, which the planner transferred on to the safe work pack, he did not notice this discrepancy because the mileages matched his expectation of the location of the bridge work being east of Dundee. The planner also stated that his workload was high (although not exceptionally so) at the time, and that this may have influenced his decision-making.

The safe work pack that the planner produced was a standard format and contained 37 pages, the first 19 of which provided substantive information about the line blockage. Four pages showed maps and diagrams of the area east of Dundee; these are followed by a form used to set up the line blockage with the signaller. The form referenced signals and locations east of Dundee (consistent with the maps and diagrams), but also gave brief details of the work, including the bridge structure number, which implicitly referred to the route west of Dundee. The structure number also appears on pages 1 and 2 of the safe work pack.

Network Rail’s processes for planning track work intend that the person in charge of work on site (PiC) plays an active part in the planning process, checking and accepting or rejecting the safe work pack as appropriate. Witness evidence suggests that this was not routinely happening for the people involved in this incident; on this occasion, there was no face-to-face meeting between the planner and the PiC involved. The safe work pack was passed to the PiC, who received, checked and accepted it about a week before the work was due to take place.

The PiC’s main concern in checking the pack was to confirm that the protecting signals covered the appropriate mileage. He also checked the nature and location of the work, finding out the (correct) location of the bridge from the person who raised the original track access request. Because the mileage of the bridge appeared to match the mileages of the protection, he did not notice the additional detail in the pack that showed the protection was actually east of Dundee.

The process then requires a responsible manager to check and authorise the safe work pack. The responsible manager involved had just resumed his post after being engaged with another project in the business for several weeks. Consequently, he did not have much prior knowledge of this piece of work, and he also had a significant backlog to address. He perceived the work on the bridge to be a routine job, and he also had confidence in the planner and the PiC who had already prepared and checked the safe work pack. Given these constraints and influences, the responsible manager conducted a cursory check of the safe work pack before authorising it.

On the night of the incident, the PiC arrived at the bridge location with the other track workers. He had the safe work pack with him, as well as a 50-page work package plan, which contained additional detail about the work to be carried out. The work package plan contained photographs and a map referring to the location of the bridge; it did not include information about the line blockage. The PiC used the photographs and the structure number to confirm that he was in the correct location when he arrived on site.

At 00:19 hrs on 10 July 2018, the PiC contacted the signaller at Dundee (who controlled the areas covering both the site of work and the line blockage) to set up the line blockage. Together, they went through the line blockage form from the safe work pack. During this conversation, the PiC cited the bridge structure number, while the signaller referred to the locations and signals east of Dundee, as per the form. They also agreed that the use of additional protection, such as detonators or track circuit operating devices, was not required because the work, as planned, did not affect the safety of the line. Based on his reading of the work package plan, the PiC was confident that he was in the correct location for the work and, based on the safe work pack, believed that the line blockage protected him because the mileages in the two documents appeared to be consistent.

After the near miss occurred, the PiC contacted the signaller again to report the incident. The signaller asked the PiC for a landmark to confirm his location, and the PiC reported that he was near the airport (this information was not requested or given in the earlier conversation; such landmarks are not part of the line blockage form). Having received this information, the signaller commented that the PiC was in the wrong place for the line blockage that had been set up.

4. Previous similar occurrence

RAIB report 16/2017 describes a near miss with track workers at Camden Junction South, London, which occurred when a signaller authorised track workers to go onto a line over which he had just routed a train, having overlooked the fact that engineering work was taking place on that line. One of the causal factors of that incident was the layout and formatting of information on paperwork that the signaller used to set up protection for the engineering work. The RAIB made a recommendation to improve the layout and formatting of such paperwork.