Runaway of two coaches at Bitton, Avon Valley Railway, 25 July 2018

Published 22 October 2018

1. Important safety messages

This accident demonstrates the importance of:

- proper securing of stabled vehicles

- planning shunting operations so that no unintended movements occur

- the correct selection and application of chocks

- stabling vehicles where there are suitable mitigations in place to prevent runaways impinging on a running line

- the need for particular care when shunting on a running line in areas with significant gradients

2. Summary of the accident

On 25 July 2018 at around 17:15 hrs, two empty coaches ran away for approximately 40 metres during shunting operations at Bitton station on the Avon Valley Railway. A small diesel engine and another coach had been uncoupled from the two coaches as the first part of a shunting operation to re-form the train for the following day’s operations. The uncoupled coaches began to run away along the platform loop line on which they had been stabled, down a gradient, towards a gated cycle and footpath crossing.

Fortunately the coaches stopped when the flange of the right hand wheel of the leading axle of the first coach became stuck in the converging switch and stock rails of a set of points. At the same time, the leading coach collided with the level crossing gate, bending it and pushing it open over about one third of the width of the crossing.

The level crossing is for pedestrians and cyclists using the Bristol and Bath railway path, a 13 mile (20.9 km) route running between Bath and Bristol city centres. The gates are usually closed against the railway to permit pedestrians and cyclists free access. When a train needs to run over the crossing, a crossing keeper closes the gates across the pathway. The railway path was busy at the time of the accident, and CCTV evidence shows that two cyclists and one pedestrian passed over it in the twenty seconds before the coaches struck the gate.

The stopping position of the leading coach (photograph courtesy of the Avon Valley Railway)

3. Cause of the accident

The accident happened because the two coaches were not properly secured after they were uncoupled from the locomotive, which had its parking (hand) brake applied, and the third coach. The coaches, of the British Railways Mark 1 design dating from the 1950s, were equipped with vacuum brakes, but these are only effective once vacuum has been created in the actuating cylinders and reservoirs. The brakes are applied when vacuum in the pipes connecting the vehicles is destroyed, or if the pipes are disconnected. When coaches are stabled, the vacuum in the cylinders and reservoirs will leak away over time, making the brakes on the vehicles ineffective. None of these coaches was fitted with a handbrake.

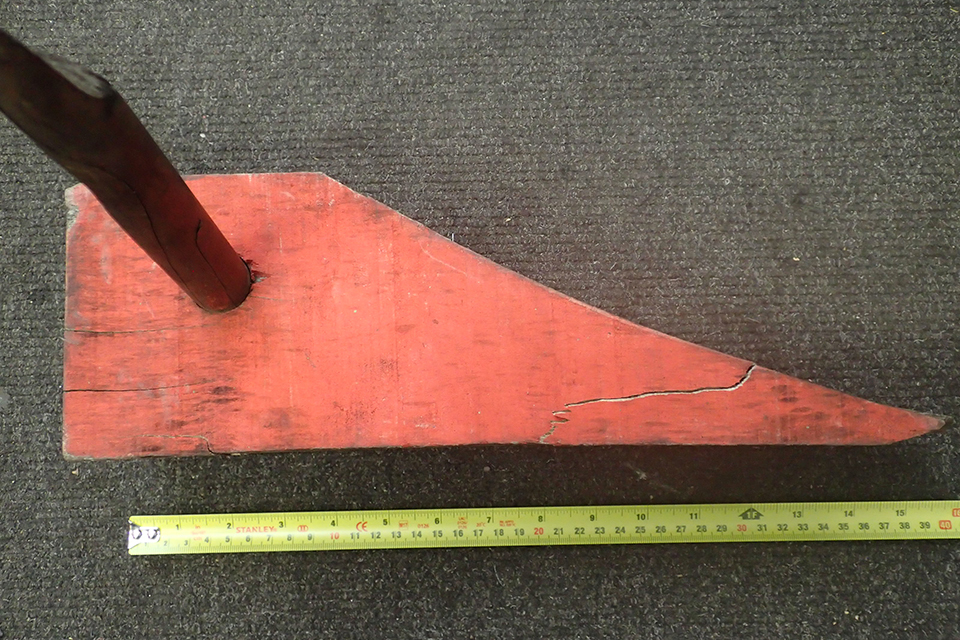

In order to uncouple, the driver was asked by the shunter to ‘ease up’ to enable the coupling to be released, without a vacuum having been created in the rear two coaches. The ‘easing up’ movement compressed the buffers. On being uncoupled, the energy stored in this way gave an impulse to the coaches, which started them moving, and overcame the chocks which were intended to restrain them. Two wooden chocks, which were not the correct profile for the wheels of the coaches, had been placed against two wheels, both on the same axle. Only a visual check had been done to check the chocks were present, rather than a physical check to ensure the chocks were correctly and firmly up against the wheels to prevent any movement. When the coaches began to move, one of the chocks was pushed aside and damaged, and the other was destroyed (see images below).

The remains of the destroyed chock (photograph courtesy of the Avon Valley Railway)

The damaged chock

One of the recommendations from the Avon Valley Railway’s own investigation into this accident was that prior to dividing rakes, the vacuum should be created and then destroyed to create an automatic brake, removing the reliance on the chocks preventing any unintended movement. This instruction was not previously captured in any Avon Valley Railway documentation.

There was no trap point or other mitigation (such as a braked vehicle or derailer) in place to prevent vehicles from running away from where they were stabled onto the main line, over the level crossing and continuing for nearly 1.5 miles (2.4 km) to Avon Riverside, the Avon Valley Railway’s southern terminus (as the downhill gradient continues until close to the end of the line).

On UK railways, trap points or derailers have historically been provided at the exits from sidings to prevent vehicles which move away from where they have been stabled from impinging on running lines. The Office and Rail and Road’s Goal setting principles for Railway Health and Safety (January 2017) principle 3.7; Stabling areas safe for people. The railway system should provide for the safe marshalling, stabling, servicing and maintenance of trains. In order to achieve the outcome, paragraph 3.7c states that railways should at least consider any incline in relation to runaway trains.

The sidings at Bitton are equipped with these devices, but the platform loop line, which is used by passenger trains, is not. For many years, the railway has stabled vehicles in this loop. Witness evidence indicates that usually, when coaches are stabled there is a braked vehicle (ie a coach equipped with a handbrake) at the downhill end of the rake. However, the railway only has two such vehicles, and at the time of the accident one was at the rear of the passenger train stabled in the adjacent platform line, and the second was undergoing maintenance.

4. Previous similar occurrences

RAIB report 04/2015 ‘Runaway and subsequent collision near Loughborough Central station, Great Central Railway’ describes an accident in which an unattended train ran away for a distance of around 1.8 miles (2.9 km) before colliding with a set of coaches. Nobody was injured as a result of the collision, although significant damage was sustained by some of the rail vehicles involved. The train which ran away had been previously left unattended on a main line. It consisted of a locomotive, coupled to a single coach. The RAIB’s investigation found that, before the train was left unattended, the air brakes on the locomotive had been applied by the driver and a single wheel scotch had been positioned against one of the locomotive’s wheels by a member of staff. The handbrakes on the locomotive were not applied and the coach was not secured with either brakes or a wheel scotch. The train ran away because the wheel scotch was positioned against the locomotive’s wheel in a way which made it ineffective.

RAIB is currently investigating an incident that occurred at around 11:15 hrs on Thursday 15 March 2018 on the East Lancashire Railway. A group of track workers were working north of Ramsbottom station. They were using an unbraked trolley to transport ballast along the line in a section where the prevailing gradient is between 1:264 and 1:140.

After being loaded with approximately 0.5 tonnes of ballast, three members of the team began to move the trolley southwards, downhill towards Ramsbottom station. Almost immediately the trolley began to run away and the track workers were unable to stop it.

The trolley continued south until it reached the level crossing at the station. The wooden gates at the crossing were closed across the railway, allowing road traffic to pass. The trolley struck the gates and derailed, damaging and displacing one of the gates into the road and spilling ballast onto the road. Although the road was open to traffic no one was injured.