Apply to manufacture authorised veterinary medicines or exempt products for small pet animals

How to apply for an authorisation to manufacture authorised veterinary medicines or medicines marketed under the Exemptions for small pet animals.

You need an authorisation to manufacture:

- an authorised veterinary medicine

- a medicine marketed under Schedule 6 of the Veterinary Medicines Regulations (Exemptions for small pet animals)

If you require an authorisation to manufacture:

- an extemporaneous preparation for administration to an animal under the prescribing cascade (also known as a ‘special’)

- a veterinary autogenous vaccine

- a stem cell product or blood product for administration to non-food animals

go to Specific Manufacturing Authorisations.

Manufacturers of human and veterinary medicines

If you manufacture human medicines and want to additionally manufacture veterinary medicines, you should refer to guidance published by the Medicines and Healthcare products Regulatory Agency (MHRA). The MHRA publishes a public register of these sites.

Authorisation to manufacture an authorised veterinary medicine (ManA)

You must hold a manufacturing authorisation (ManA) to carry out any of the following activities in relation to an authorised veterinary medicine:

- the manufacture of a veterinary medicine whether for use in Great Britain or another country

- the carrying out of any part of the manufacturing process in bringing a veterinary medicine to its final state including; processing, assembling, packaging or repackaging, labelling or relabelling, storing, sterilising or releasing for supply of a veterinary medicine

- the importation of any veterinary medicine for use in Great Britain, other than in accordance with the cascade

You do not need a ManA to:

- prepare, divide up, change the packaging or presentation of a veterinary medicine where this is done solely for retail supply, by or under the supervision of a veterinary surgeon or pharmacist in a registered veterinary practice premises or pharmacy. A pharmacist may not break the immediate packaging of sterile products

- manufacture a veterinary medicine based on radio-active isotopes

- manufacture a veterinary medicine for administration for research purposes in accordance with an Animal Test Certificate (ATC) or a licence issued under the Animals (Scientific Procedures) Act (A(SP)A) 1986

Your manufacturing site and its operations will be inspected for compliance with the Veterinary Medicines Regulations (VMR) and current good manufacturing practice (GMP).

Duties on ManA holders

You must comply, where appropriate to the manufacturing steps performed, with the following requirements relating to your authorisation:

- manufacture the veterinary medicine in accordance with its marketing authorisation (MA)

- have permanently at your disposal the services of at least one Qualified Person (QP) and ensure that all necessary documents, premises and technical and other facilities are placed at that person’s disposal to enable them to discharge their duties

- have permanently at your disposal the services of a Production Manager (PM) and a person responsible for quality control (QC Manager)

- comply with current GMP and process a GMP certificate issued by a UK national competent authority

- ensure that you have quality assurance (QA) and quality control (QC) systems in place

- ensure that the finished product is labelled with:

- its name, strength and pharmaceutical form

- its batch number

- its expiry date

- its storage requirements

- any warnings required for safe handling of the product

- ensure that you retain a representative sample of the finished product and make it available to us for testing, if requested

- ensure each batch of product manufactured or imported is batch (QC) tested to confirm that it meets its required specification before being certified/released to the market by the QP. The QP may accept batch testing carried out in a country with which the UK has a mutual recognition agreement – see batch certification below

- inform us and the marketing authorisation holder, if applicable, where you obtain information that a veterinary medicine that falls within the scope of your authorisation is falsified, or is suspected of being falsified, irrespective of whether the product was distributed within the legal supply chain or by illegal means

- keep detailed records of each batch of veterinary medicine you manufacture or import, as required by GMP, and all certification provided by the QP in relation to that batch

- keep the following details of all veterinary medicines you supply:

- the name of the veterinary medicine and its marketing authorisation number if applicable

- the pharmaceutical form and strength of the product

- the quantity of product supplied

- the batch number and expiry date

- the date of the transaction on which the product was supplied

- the company name and the permanent address or registered place of business of the recipient.

Good Manufacturing Practice (GMP)

GMP is defined as the part of quality assurance which ensures that products are consistently produced and controlled in accordance with the quality standards appropriate to their intended use and as required by the applicable marketing authorisation or product specification.

You must manufacture veterinary medicines in accordance with GMP, which includes:

- conducting the manufacturing operations in accordance with a pharmaceutical quality system (PQS), which must be:

- clear

- systematically reviewed from time to time in the light of experience

- capable of consistently manufacturing veterinary medicines which are of the required quality and which meet the requirements of the relevant marketing authorisation.

- the critical steps of the manufacturing process set out in the PQS must be validated

- any significant amendments to the manufacturing process must be validated

- the PQS must provide for:

- appropriately qualified and trained personnel

- adequate premises and space

- suitable equipment and access to services

- suitable materials, containers and labelling

- relevant procedures and instructions

- suitable storage and transport

- investigation into complaints and defects

- any significant deviations from its provisions to be fully recorded and investigated, with appropriate corrective and preventative action implemented

- ensuring that you keep records of your manufacturing process, including distribution, in a comprehensible and accessible form for five years after the date on which you place the veterinary medicine on the market or for one year after the expiry date of the batch of veterinary medicine, whichever is the longest

Detailed principles and guidelines for GMP are included in Eudralex volume 4.

Requirements for active substances used as starting materials

You may only use as starting materials active substances, also known as active pharmaceutical ingredients or APIs, that have been manufactured in accordance with Eudralex Volume 4, Part II. and distributed in accordance with good distribution practice for active substances.

You must verify that each manufacturer, importer or distributor in Great Britain from whom you obtain active substances is appropriately registered and carry out risk-based audits on those suppliers.

If you are the manufacturer of the final dosage form, you must evaluate the suitability of all of your active substance suppliers, wherever they are located, for example by:

- supplier audit, and

- provision of a QP declaration concerning GMP compliance of the active substance manufacture

For further information about manufacture, importation and distribution of active substances refer to Apply to register as a manufacturer, importer or distributor of active substances for veterinary medicines.

Transmissible Spongiform Encephalopathy (TSE)

You must comply with the guidance on minimising the risk of transmitting animal spongiform encephalopathy agents via veterinary medicinal products.

Required Personnel

You must appoint the following personnel

Qualified Person (QP)

The QP’s role is to ensure that each batch of veterinary medicine manufactured under their responsibility is manufactured in compliance with the VMR and tested to ensure that the product meets the specification in its marketing authorisation. The QP’s full role and responsibilities are defined in Eudralex Volume 4, Chapter 2 and Annex 16.

At least one QP must be named on your manufacturing authorisation and must be permanently and continuously at your disposal.

QPs must meet specific educational and vocational requirements and be a member of one of the following professional bodies:

-

Royal Society of Chemistry

-

Royal Society of Biology

-

Royal Pharmaceutical Society

-

or registered with the Pharmaceutical Society of Northern Ireland

These professional bodies jointly undertake assessment of the candidate’s eligibility on our behalf.

QPs must comply with the QP Code of Practice.

Exceptionally Appointed QPs

We may exceptionally appoint someone as a QP who is not a member of one of the professional bodies but only for a specific site and a specific product, provided that we are satisfied that the person has the educational qualifications and practical experience to carry out the QP’s duties.

Production Manager (PM)

You must also have a named Production Manager (PM) responsible for production. Their role and responsibilities are defined in Eudralex Volume 4, Chapter 2.

Quality Control (QC) Manager

You must also have a Quality Control (QC) Manager. The QC Manager may also be the QP but cannot be the same person as the Production Manager. Their role and responsibilities are defined in Eudralex Volume 4, Chapter 2.

Batch certification for release

You may apply for a ManA solely to certify and release batches of products manufactured by a third party manufacturer.

The QP named on a ManA granted solely for the purpose of batch certification for release may either take responsibility for all manufacturing stages conducted by the third party manufacturer or may take account of confirmation from the third party’s QP that the batch has been manufactured in compliance with the product’s MA and the requirements of GMP. However, ultimate responsibility for certification of the batch for release to market lies with the certifying QP.

Veterinary medicines manufactured outside the UK must be imported via a ManA holder’s site and also batch (QC) tested, QP certified and released. In the case of importation from a country with which the UK has a formal agreement which includes mutual recognition of batch (QC) testing, the importing ManA holder’s QP may accept the batch testing carried out in the other country.

The EU and UK Trade and Cooperation Agreement

The Trade and Cooperation Agreement (TCA) between the EU and the UK sets out the conditions for the mutual recognition of GMP certificates issued by their National Competent Authorities (NCAs) for medicinal products, including veterinary medicines.

Although mutual recognition of batch (QC) testing was not included in the TCA, since EU Exit we have adopted a transitional approach to the batch testing and release of products imported from the EU. UK authorised products that have been QP certified and released in the EU may be imported by the holder of a veterinary wholesale dealer authorisation (WDA).

Export from UK

Veterinary medicines manufactured in Great Britain should be produced to the same standards irrespective of where they will be used. If you are manufacturing medicines exclusively for export you must hold a ManA and comply with GMP.

Authorisation to manufacture a medicine marketed under the Exemptions for small pet animals (SAM)

Medicines manufactured under Schedule 6 of the Veterinary Medicines Regulations (Exemptions for small pet animals) must be manufactured by the holder of a ManA or a Small Animal Medicines manufacturing authorisation (SAM).

We may also accept products manufactured at a site in a country that the UK has a formal agreement with that includes mutual recognition of GMP or a country which we consider has standards of GMP that are at least equivalent to those in Great Britain.

As the holder of SAM you must comply with the same general requirements as a ManA holder, including having the services of a QP, PM and QC Manager permanently at your disposal.

For further information, including registration and labelling requirements, see guidance for Exemptions for small pet animals.

Wholesale supply

As the holder of a ManA or SAM you may store and distribute any veterinary medicine manufactured or imported in line with your authorisation. However, if you buy or store any other veterinary medicine to supply to a wholesale dealer or retailer, you must hold a wholesale dealer authorisation (WDA), see Veterinary medicine wholesale dealer’s authorisation

If you wholesale supply a veterinary medicine that you have manufactured or imported, you must:

- comply with the principles of Good Distribution Practice (GDP)

- only distribute the medicine to another person who is entitled to supply the product under the VMR, either by wholesale or retail.

Application Procedure

Complete and submit your application for a ManA or SAM, together with a Site Master File (SMF) either by email to: inspections@vmd.gov.uk or submit it via our Veterinary Medicines Digital Service

- Application form for

- Application form for

- Application form for

Before completing your application, you may find it helpful to read pages 181-197 of the Compilation of Community Procedures.

Procedure for authorisation and time lines

We will validate your application within 10 days of receiving it, provided you’ve submitted all required information. The validation time will be extended if we request further information from you.

After validation we will carry out a pre-authorisation inspection of your site within 90 days to assess its suitability, and the suitability of your staff, technical equipment, facilities and documented quality system.

Following the pre-authorisation inspection, if we are satisfied that your site is suitable for the intended purpose we will grant the ManA or SAM and issue you with a GMP certificate.

If we are not satisfied that the suitability of your site or other requirements, we may either refuse to grant the authorisation or grant you a conditional authorisation that is time-limited in order for you to address deficiencies observed.

In these cases we will notify you of the reason and how you can appeal our decision .

Validity of authorisations

Your authorisation will remain valid subject to satisfactory re-inspection of your manufacturing site.

Variation, Suspension and Revocation of an Authorisation

Voluntary variation (Change)

You must submit a variation application to us if the details of your ManA or SAM change. There are two types of variation: administrative and scientific.

Administrative variations do not require assessment by an inspector. Examples include:

- change of company name/trading name

- change of owner

- change of site address (administrative rather than site location for example, postcode change)

- removal of a QP, PM or QC Manager (providing that there is more than one)

- change or addition of PM or QC Manager

- removal of a named site

- removal of a product type

Scientific variations require assessment by an inspector and may also require an inspection. Examples include:

- addition of a new manufacturing activity

- addition of categories of products handled at the site

- addition of new site

- change of site location

- change or addition of a QP

Application form for

Compulsory variation, suspension or revocation

We may vary, suspend or revoke your ManA or SAM if:

- you have not complied with the VMR, including failing to comply with GMP

- you have manufactured a type of veterinary medicine which is not authorised by your manufacturing authorisation

- you have produced a veterinary medicine outside the terms of its MA

- your premises or equipment is no longer suitable

- your registered QP, QC Manager or PM is not fulfilling their duties

- you have not carried out the activity specified in your authorisation for 5 years or more

- you have not paid a required fee

In all cases, we will notify you of the reason for suspending, varying or revoking your authorisation and tell you how you can appeal the decision.

Inspections

Pre-authorisation inspection

Before issuing a ManA or SAM, we will normally carry out a pre-authorisation inspection of your site, and any site(s) where quality control testing or other activity is contracted to a third party unless that site has already been inspected by us or the MHRA.

Scheduled inspection

We will periodically inspect your site(s) to ensure that you are complying with the VMR.

Inspectors are authorised under the VMR to:

- inspect the site, organisational arrangements and procedures used in the storage and distribution of medicinal products

- interview key personnel named on the authorisation

- take samples

- have access to, and inspect and copy or seize any documentation or records, in whatever form they are held, relating to the manufacture, assembly, storage and distribution of veterinary medicines

We conduct inspections on a risk basis, taking into account the products manufactured and the compliance findings of the previous inspection, although inspections will normally take place at least every 3 years.

We will agree with you an inspection date and share the main areas that will be covered during the inspection to help you prepare.

After the inspection, we will send you an inspection deficiency report within 30 days. You should respond to any deficiencies cited within 30 days of receiving it.

Once we are satisfied with your response, we will issue a final GMP inspection report and a GMP certificate within 90 days following the end of the inspection.

GMP certificates are only issued to ManA and SAM holders, contract QC test sites and to manufacturing facilities located outside the UK that we inspect.

Deficiencies

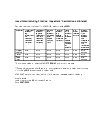

Deficiencies are categorised as:

Other Deficiencies

These are:

- unlikely to pose a potential risk to human or animal health, or the environment

- does not indicate a significant deviation from the requirements of the VMR, Codes of Practice or Guidance

- cannot be classified as either critical or major because there is insufficient information to classify it as such

Major Deficiencies

These are:

- non-critical but has produced, or has the potential to produce, a possible risk to human or animal health or the environment

- a major deviation from the requirements of the VMR

- a failure to carry out satisfactory procedures to ensure that products are manufactured, stored or distributed in accordance with their specific requirements

- a combination of a number of related other deficiencies, none of which on their own may be major, but which may together represent a major deficiency and should be explained and reported as such

- other deficiencies that have been brought to the attention of the business on previous occasions but have not been resolved

Critical Deficiencies

These are:

- deficiencies that have produced, or have the potential to produce, a significant risk to human or animal health, or the environment

- a significant deviation from the requirements of the VMR through serious negligence or intent

Inspections are scheduled at intervals based on the number and type of deficiencies noted during an inspection, as follows:

- sites with no critical or major deficiencies are rated ‘Good’ and given a next inspection interval of 33 months

- sites with no critical deficiencies and less than 6 major deficiencies are rated ‘Acceptable’ and given a next inspection interval of 24 months

- sites with at least one critical deficiency or 6 or more major deficiencies are rated ‘Poor’ and given a next inspection interval of 12 months.

We may inspect sites in countries outside of the UK that we do not have a mutual recognition agreement (MRA) with.

Fees

Fees are payable for:

- processing an application for a ManA or SAM

- a pre-authorisation inspection of each site and subsequent risk-based inspections

- an annual fee

- processing a variation application to an existing ManA or SAM

- issuing duplicate or multiple GMP certificates

Fees payable by manufacturers for GB

Fees payable by manufacturers for NI

Fees applied to animal medicine authorisation applications are not refundable or transferable.

Register

Your details will be published in the register of ManA holders and SAM holders.

Inspectors Declarations of Interest

We require our inspectors who perform GMP inspections to sign a Declaration of Interests (DoI) every year, to ensure that they do not have any financial or other interests that could affect their impartiality. Their DoIs are published below in the interest of transparency and to support the sharing of information with our regulatory partners.

Contact Us

You can email us at: inspections@vmd.gov.uk.

The Veterinary Medicines Regulations

For detailed requirements refer to the Veterinary Medicines Regulations 2013 (legislation.gov.uk)

Updates to this page

-

Added clarification under heading The EU and UK Trade and Cooperation Agreement.

-

Updated to reflect changes to the VMR.

-

Guidance on manufacturing extemporaneous preparations for administration to animals under the prescribing cascade has been moved to the guidance page ‘Specific Manufacturing Authorisations’ and the format of the retained guidance changed. The VMD Inspectors’ Declarations of Interests has been updated.

-

The new ManSA register has been uploaded.

-

VMD Inspectors declaration of Interests added

-

Updated in accordance with end of Transition Period.

-

Update to register of ManSA register

-

Updated ManA application and variation forms

-

Update to the Register of Sites that hold a Manufacturer’s “Specials” Authorisation

-

Register of Sites that hold a Manufacturer’s “Specials” Authorisation Updated: 01 November 2019

-

Updated register of Specials manufacturers

-

Reviewed and updated to include Apply for guidance

-

Updated Register of ManSA sites

-

Updated Register of Specials manufacturing sites

-

Updated Specials Register of Sites

-

Register of Sites that hold a Manufacturer’s “Specials” Authorisation updated

-

Updated Specials Register

-

Updated registers

-

First published.