5. Wheels, tyres and suspension

Wheel bearing, wheel and tyre, and suspension (including springs, shock absorbers, and suspension arms and joints) rules and inspection for motorcycle MOT tests.

5.1.1. Not in use

5.1.2. Not in use

5.1.3. Wheel bearings

To assess the wheel bearings:

-

With each wheel raised clear of the ground, including any sidecar wheel, rock the wheel by hand to check for excessive play in the wheel bearings.

-

Spin the wheel and listen for roughness in the bearings.

| Defect reference | Defect description | Category |

|---|---|---|

| (a)(i) | A wheel bearing with excessive play | Major |

| (a)(ii) | A wheel bearing play so excessive it is likely to break up or directional control impaired | Dangerous |

| (b)(i) | A wheel bearing excessively rough | Major |

| (b)(ii) | A wheel bearing so rough it is likely to overheat or break up | Dangerous |

5.2.1. Road wheel security

Check that each wheel, including any sidecar wheel and its associated fixings are present and secure. Also check the condition of each wheel hub.

| Defect reference | Defect description | Category |

|---|---|---|

| (a)(i) | A wheel with a loose or missing wheel nut, bolt or stud in the case of multiple fixings | Major |

| (a)(ii) | A wheel with a loose or missing wheel nut, bolt or stud in the case of a single fixing, or more than one loose or missing in the case of multiple fixings | Dangerous |

| (b)(i) | A wheel hub excessively worn or damaged | Major |

| (b)(ii) | A wheel hub worn or damaged to the extent that wheel security is adversely affected | Dangerous |

| (c)(i) | A wheel spindle loose | Major |

| (c)(ii) | A wheel spindle a wheel spindle or its securing nut(s) so insecure that wheel security or steering control is adversely affected | Dangerous |

| (d) | A wheel spindle locking device missing or ineffective | Major |

5.2.2. Road wheel condition

Check the roadwheels fitted to the motorcycle and any sidecar.

Spare wheels are not included in the inspection, but you should tell the presenter if you notice a defect.

The maximum lateral rim distortion (run out or buckling) limits are:

- 4mm for steel rims

- 2mm for aluminium alloy rims (cast or fabricated)

The maximum eccentricity is 3mm for all types of rim.

Measurements should be taken from a machined surface in the case of cast aluminium alloy rims.

| Defect reference | Defect description | Category |

|---|---|---|

| (a) | Any fracture or welding defect on a wheel | Dangerous |

| (b) | Not in use | |

| (c)(i) | A wheel excessively corroded, damaged or distorted | Major |

| (c)(ii) | A wheel corroded, damaged or distorted to the extent that control of the motorcycle is likely to be adversely affected | Dangerous |

| (d) | A spoke missing, cracked, excessively loose, bent or corroded | Major |

| (e)(i) | A built-up wheel with loose or missing rivets or bolts | Major |

| (e)(ii) | A built-up wheel with rivets or bolts missing or loose to the extent that control of the motorcycle is likely to be adversely affected | Dangerous |

5.2.3. Tyres

Spare tyres are not included in the inspection, but you should tell the presenter if you notice a defect.

Size and type

The aspect ratio of a tyre is included in the size marking. For example, a 170/55R17 has an aspect ratio of 55%. On motorcycles with twin front or rear wheels, check that each tyre on the ‘axle’ is the same size and structure.

Examples of an unsuitable tyre are:

- a sidecar or car tyre on a solo motorcycle - sidecars may be fitted with either car or motorcycle type tyres

- a tyre specifically designed for front wheel use fitted to the rear wheel

- a bias belted tyre fitted to the front with a cross-ply tyre fitted to the rear

- a radial tyre fitted to the front and a cross-ply or bias belted tyre fitted to the rear.

Additionally, motocross tyres, tyres designated by their manufacturer as racing tyres and tyres marked ‘NHS’ or ‘NOT FOR HIGHWAY USE’ on the sidewall are also unsuitable, unless the tyre sidewall is marked with:

- an ‘E’ in a circle

- an ‘e’ in a rectangle

- JIS (Japanese industry standard)

- DOT (American standard)

Motocross tyres are deemed to be those where the space between tread blocks is substantially greater than the size of the blocks themselves.

Directional tyres must be fitted as instructed on the sidewall. They may use arrow and/or words to indicate the direction of forward rotation.

Condition and fitment

You must reject a tyre if:

- it’s damaged to the extent that the ply or cord is exposed

- it has a lump, bulge or tear caused by separation or partial failure of its structure

- the tread rubber is lifting

On a radial ply tyre, you should take care to distinguish between normal undulations in the carcass, resulting from manufacturing, and lumps or bulges caused by structural deterioration.

When assessing cuts in a tyre, you can use a blunt instrument to open a cut to check whether the cut is deep enough to reach the ply or cord. You should take care not to cause further damage.

When assessing a cut in a tyre, you must reject the tyre if:

- ply or cord can be seen without touching the tyre

- exposed ply or cord can be seen - irrespective of the size of the cut - by folding back rubber or opening a cut with a blunt instrument

- cords can be felt but not seen when a cut more than 25mm or 10% of the section width - whichever is the greater - is opened with a blunt instrument

Before failing a tyre due to being able to feel the cords in a cut, you must ensure that you can feel the cords and not some other object. If you are not sure, then you should pass and advise.

Loose or missing tyre security bolts are not a defect, if you notice them you should tell the presenter.

Tread depth

A tread pattern is the combination of plain surfaces and grooves extending across the breadth of the tread and around the entire circumference. It excludes any tie-bars, tread wear indicators, or features designed to wear out substantially before the remainder of the pattern, and other minor features.

Grooves containing tread wear indicators (TWI) or grooves cut as deep as those containing the wear indicators when new, are considered to be primary grooves. Other grooves or sipes that are not cut as deep as the primary grooves are secondary grooves and do not need to be considered when assessing tread depth.

The ‘breadth of tread’ is the part of the tyre which can contact the road under normal use, including cornering.

The tread pattern must:

- be visible over the whole tread area

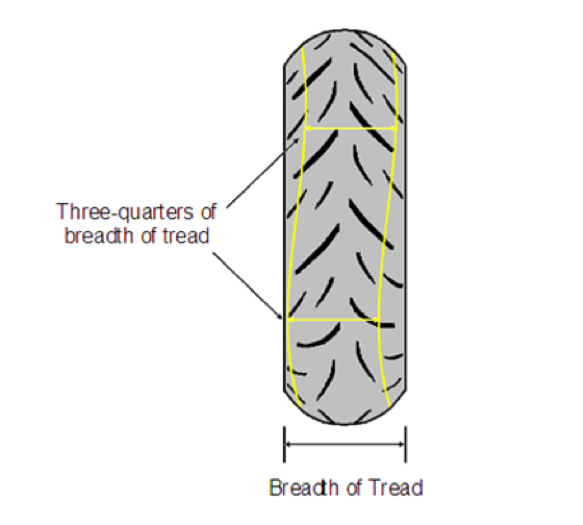

- have a depth of at least 1.0mm throughout a single band of at least 3/4 over any section of the breadth of tread round the entire outer tyre circumference

The whole tread width must have at least 1.0mm deep tread if the original tread pattern did not extend beyond 3/4 of the tyre width when new.

The continuous band of 1mm tread depth over 3/4 of the breadth of tread does not have to run parallel to the tyre centre line (see Diagram 1).

Motorcycles with an engine capacity not greater than 50cc do not need to have 1mm of tread. However, they must have a visible tread pattern around the entire circumference and across the whole breadth of the tread.

Diagram 1. Example of tyre tread area, depth and width

| Defect reference | Defect description | Category |

|---|---|---|

| (a) | An unsuitable tyre fitted | Major |

| (b) | Tyres on twin wheels are different sizes | Major |

| (c) | Tyres on twin wheels of different structure | Major |

| (d)(i) | A tyre with a cut in excess of the requirements deep enough to reach the ply or cords | Major |

| (d)(ii) | A tyre with a lump, bulge or tear caused by separation or partial failure of its structure, including any lifting of the tread rubber or with cords exposed or damaged | Dangerous |

| (e) | Tyre tread depth not in accordance with the requirements | Dangerous |

| (f) | A tyre fouling another component | Major |

| (g) | A tyre with a recut tread fitted | Major |

| (h) | Not in use | |

| (i) | A tyre not fitted in compliance with the manufacturer’s sidewall instructions | Major |

| (j) | A tyre valve seriously damaged or misaligned likely to cause sudden deflation of the tyre | Dangerous |

| (k) | A tyre incorrectly seated on the wheel rim | Major |

5.3.1. Springs

Some motorcycles are not fitted with rear suspension.

Unsafe modifications include:

- welded repairs

- the use of excessive heat to highly stressed components (see Appendix A)

- modifications likely to affect the roadworthiness of the motorcycle

| Defect reference | Defect description | Category |

|---|---|---|

| (a)(i) | A spring insecurely attached | Major |

| (a)(ii) | A spring so insecure that control of the motorcycle is likely to be adversely affected | Dangerous |

| (b)(i) | A spring or spring component fractured or seriously weakened | Major |

| (b)(ii) | A spring main leaf fractured | Dangerous |

| (c)(i) | A spring missing | Major |

| (c)(ii) | A spring missing and control of the motorcycle is likely to be adversely affected | Dangerous |

| (d) | A spring with an unsafe modification | Major |

5.3.2. Shock absorbers

A missing shock absorber should only be rejected if they were fitted as standard.

On most motorcycles front shock absorbers will be incorporated into front forks.

Some smaller motorcycles are not fitted with shock absorbers on the front suspension.

If twin shock absorbers are fitted and they do not seem to be equally adjusted, you should inform the presenter.

On motorcycles with anti-dive front suspension which restricts front suspension movement when the brake is applied, it may be necessary to place the front wheel against a wall when checking the effectiveness of the shock absorber(s).

Light misting on a suspension shock absorber causing thin film of fluid is not considered a defect.

Rubber fork gaiters may be pulled back to assess oil leakage from a shock absorber if it’s possible to do without dismantling or damage. You must make sure to refit them correctly.

| Defect reference | Defect description | Category |

|---|---|---|

| (a)(i) | A shock absorber insecurely attached | Major |

| (a)(ii) | A shock absorber missing or likely to become detached | Dangerous |

| (b) | A shock absorber not functioning or leaking severely | Major |

| (c) | A shock absorber bush excessively worn | Major |

5.3.3. Suspension arms, rods, linkage etc.

Some motorcycles are not fitted with rear suspension.

To fully access rear suspension components it may be necessary to remove side panels or the seat to carry out a full examination.

With mono-shock type suspension some linkage movement may be observed when the rear suspension is ‘hanging’.

On machines without a centre stand, suitable equipment must be used to raise the wheels clear of the ground, either independently or simultaneously, using an assistant where necessary. Pulling a motorcycle over on its side-stand is not recommended.

The machine should be jacked so that the wheels are hanging free.

Some fork arrangements rely on the bracing incorporated in the mudguard fixings to maintain their alignment. If a mudguard is insecurely fixed to the forks, it may adversely affect the handling of the machine.

Unsafe modifications include:

- welded repairs

- the use of excessive heat to highly stressed components (see Appendix A)

- modifications likely to affect the roadworthiness of the motorcycle

Guidance on assessing corrosion is given in Appendix A

| Defect reference | Defect description | Category |

|---|---|---|

| (a)(i) | A suspension component insecurely attached | Major |

| (a)(ii) | A suspension component missing, likely to become detached or control of the motorcycle impaired | Dangerous |

| (b)(i) | A suspension component excessively damaged or corroded | Major |

| (b)(ii) | A suspension component fractured or likely to fail | Dangerous |

| (c)(i) | A suspension component with an unsafe modification | Major |

| (c)(ii) | A suspension component modified so that the suspension is inoperative or likely to foul other components | Dangerous |

| (d) | Excessive wear or free play in a suspension component | Major |

5.3.4. Suspension joints, pins and bushes

Some motorcycles are not fitted with rear suspension.

To fully access rear suspension components it may be necessary to remove side panels or the seat to carry out a full examination.

With mono-shock type suspension some linkage movement may be observed when the suspension is in an abnormal position.

The condition of suspension pins, bushes, mountings and ball joints should be checked by attempting to move the suspension from side to side and up and down with the wheels raised and resting on hardstanding.

| Defect reference | Defect description | Category |

|---|---|---|

| (a)(i) | A suspension pin, bush or joint excessively worn | Major |

| (a)(ii) | A suspension pin, bush or joint likely to become detached | Dangerous |

| (b)(i) | A suspension joint dust cover severely deteriorated | Minor |

| (b)(ii) | A suspension joint dust cover missing or no longer prevents the ingress of dirt etc. | Major |