6. How to carry different types of load in HGVs and goods vehicles

Ways to load items on a goods vehicle safely.

The types of load in this section are listed in alphabetical order.

Abnormal loads are generally larger or heavier than ordinary plant equipment or machinery. They can cause significant harm to the driver and other road users if they become detached from the vehicle.

Operators should make a separate plan for every abnormal load movement and make sure the load is secured appropriately because of the increased risk.

You must take reasonably practicable steps to secure abnormal loads.

The most effective way to do this is with a combination of physical restraints to movement such as lashings – use chains instead of straps for heavy loads – and:

- bulkheads

- chocks or dunnage

- cradles

The load must be stable on the load bed without lashings.

You must not:

- attach more than one lashing to a single attachment point

- loop lashings through or around attachment points and then hook the lashing onto itself – this can damage the lashing and reduce its effectiveness

If the vehicle does not have a headboard and there is no reasonably practicable way of fitting a physical barrier to stop the load moving forward, you must use additional lashings, preferably chains, to achieve an equivalent level of safety. You may also need to use friction matting or a high-friction floor to reduce the risk of movement.

Wheeled or tracked equipment

If the load bed does not adequately support the equipment’s wheels or tracks, you should either:

- make sure the body is supported instead

- rest the equipment on timbers or something similar

Operator and consignor responsibilities

Operators and consignors should:

- carefully plan each abnormal load movement

- make sure that the abnormal load is secured appropriately

- agree what loading and securing scheme to use

- give any drivers or loaders that will secure the abnormal load appropriate training on how to load and secure the load

Operators and consignors must work together to provide clear instructions to drivers on:

- suitable methods of loading and securing for each load type

- how to check tension in the lashings at regular intervals

- what to do if the load shifts during the journey

They must ensure that the load complies with Road Vehicles Lighting Regulations 1989 (SI No 1796) if it obscures:

- obligatory lights

- reflectors

- rear markings

- registration plates

Check the rules for abnormal load vehicles and their escort vehicles.

You must load hay and straw bales so that their weight is fully supported by the load bed. You must make sure the stacks are stable before you secure them.

You must secure hay and straw bales carried on vehicles or open trailers using either:

- at least one lashing strap that passes over the top of each stack of bales or individual bale, and additional strapping at the front and the rear of the load

- rated nets or sheets, straps, and chains

- strapping over the top of an empty pallet (or similar items that spread the forces) placed on top of the bale to help distribute the force of the straps

- strapping to secure bales that sit above the sides of the trailers with hydraulic operated bale securing frames or clamps

Wider lashing straps can help to spread the force over the load, which can prevent it being damaged or ‘cut into’ by traditional lashing straps.

You must make sure that hay or straw does not become loose during transport and cause a hazard to other road users. The looser the bale, the more likely it is to blow off the vehicle.

If you have diagonal straps at the rear of the load in addition to straps over the top of the bales, remove these first during unloading before removing the straps that pass over the top of the bales.

When transporting boxes you should:

- place them against the headboard or within 30cm of it if possible, and secure them using lashing ratchet straps if carried on open trailers

- use additional strapping at the front and rear if the boxes are stacked

- not stack boxes more than 3 on top of each other

You should secure bulk bags by:

- using suitable nets or sheets

- strapping the load to the vehicle through the bag lifting eyelets or lifting pocket

- strapping over the top of an empty pallet placed on top of the bag to distribute the force of the straps

- using wider lashing straps to distribute the force over the load

You must:

- use at least one strap per row

- cover any open bags if the securing method does not prevent the contents spilling or blowing out

You must secure construction products, like bricks and blocks, to the vehicle. Stacks of these products must be stable without lashings.

You should load them against the headboard if possible, or within 30cm of it if not.

One frictional lashing over each row will usually be enough for most loads.

If the load is higher than the headboard, you should use at least 2 frictional lashings over the front row of the load to create a bulkhead.

You must:

- secure the last row with 2 frictional lashings

- use a frictional lashing to prevent sideways movement if you use diagonal lashing (cross strapping) to create a rear bulkhead and stop rearward movement

If you use lashing straps to create a rear bulkhead, make sure that the lashings do not go under the base of a pallet used to carry the product. The lashing must go round the load and attach to the vehicle chassis.

If you are transporting construction products on pallets, you must secure them to the pallet to form a single unit before securing the entire unit to the vehicle.

Everyone involved in transporting dangerous goods should know how to stow and secure them properly to protect:

- the driver

- other road users

- anyone in the vicinity during unloading

- the environment

If possible, you should carry dangerous goods in vehicles with:

- caged bodies

- closed bodies (including tankers)

- curtain sided bodies

If you are not carrying the dangerous goods in a closed body vehicle, you should:

- place them against a bulkhead

- secure them to the vehicle

You may need to take additional precautions if there’s a risk of ignition.

Dangerous goods regulations

You can find the full legal requirements on the transport of dangerous goods in:

- Carriage of Dangerous Goods and Use of Transportable Pressure Equipment Regulations 2009

- Agreement concerning the International Carriage of Dangerous Goods by Road

Dangerous goods safety advisers

You must have a dangerous goods safety adviser (DGSA) if you transport dangerous goods unless:

- you only do it occasionally, for example breakdown recovery vehicles

- you’re only receiving the dangerous goods (you’re the ‘consignee’)

- they’re in ‘limited quantities’

- you’re moving them a very short distance by road, for example between buildings on an industrial estate

- you’re using private vehicles

The dangerous goods safety adviser can be someone you train in-house, or you can appoint an external adviser.

Segregating dangerous goods

Some hazardous materials can react dangerously with others if they’re accidentally mixed during transport. If you’re carrying them on the same vehicle, you must secure them so that the materials cannot mix, even in a collision.

The consignor must inform the operator about any dangerous goods in the load that are incompatible.

If you are not sure, you should get additional expert advice.

You should not transport lithium batteries at the front of a mixed load. If there is a collision they could be damaged by movement of the load behind.

Gas cylinders

Gas cylinders should be either:

- carried upright or at an angle in racks designed for this purpose and fitted on the vehicle

- in lift-on-off cribs or frames

If you’re carrying cylinders individually, you must secure them using lashings. This is to prevent any movement in the load space that could damage the cylinders or other items in the load.

Protect the cylinders’ valves from damage if you are carrying them horizontally. This protection should be in addition to the standard fittings such as surrounding rings or other protective fitments.

Gas can escape under pressure if the valves become damaged. This may propel the containers with significant force.

You must not carry cylinders in the cab or footwell of any vehicle. This could cause an injury in a collision. Pressurised equipment such as fire extinguishers and cooking gas cylinders must be properly stowed.

Liquefied petroleum gas (LPG) containers must be carried upright. This is to prevent the relief device malfunctioning if it comes into contact with the liquefied gas.

If you’re carrying small numbers of cylinders in a closed van, the cargo space must be properly ventilated.

You must not carry toxic gases in the same compartment as the driver or vehicle crew.

Intermediate bulk containers (IBCs) used to carry dangerous goods

You must secure intermediate bulk containers (IBCs) used to transport dangerous goods with either:

- 2 lashing straps

- another lashing method such as a bungee tarpaulin system that distributes the securing force across the top of the IBC

This is because the skeleton frame of an IBC does not usually have a central upright. A single ratchet strap over the IBC can deform the frame and cause the load securing system to fail.

You can use one ratchet strap over the central support if a central upright is fitted.

You can secure empty IBCs with one strap if this does not damage the frame.

Inspect the IBCs before loading to make sure they’re in good condition. Check that there are no leaks, particularly around the fittings for filling and discharging.

Each IBC must have the marks required under ADR readily available for inspection.

Barrels

You should either:

- shrink-wrap and band barrels to a pallet to form a single unit

- use plastic locators if you need to minimise movement

You should then secure them to the vehicle using ratchet straps or similar.

Tanks and similar containers

Tanks can be:

- rigidly attached by twist locks or similar to a vehicle

- a tank container – where the tank is fitted inside an ISO frame (shipping container) for multi-modal transport

You must:

- properly secure the tank container to the vehicle

- make sure hatches and valves are securely closed during transport

- secure any hoses or ancillary equipment

You should examine all openings, including pressure relief devices for security and leakage, before the journey. You should have a system in place for examining non-visible openings.

Asbestos waste

When asbestos waste contains more than 0.1% asbestos it is defined as:

- ‘hazardous waste’ in England and Wales

- ‘special waste’ in Scotland

You need a hazardous waste or special waste consignment note when transporting asbestos waste.

Some manufactured products or asbestos contained within a binder such as cement or resin do not need to be transported as dangerous goods if the products are not worn or damaged.

Damaged products or fibrous and unbounded asbestos must be transported as Class 9 dangerous goods and you must follow the regulations on transporting dangerous goods.

They must be:

- double-bagged or wrapped

- labelled correctly

- transported in a closed box or solid vehicle body

Explosives

Explosives are sensitive to heat. They may be sensitive to shock as well.

You must secure explosive cargo to:

- prevent chafing and friction

- prevent impact between them during transport

You must make sure that any other items carried in the load compartment are well secured so they do not impact the explosive items. This includes things like:

- toolkits

- fire extinguishers

- other heavy equipment

You must not use combustible materials such as paper or straw as packing for explosive cargoes.

Consignors and vehicle operators are responsible for segregating explosive loads and complying with national and international regulations.

Radioactive material

Radioactive material will be packed so that it does not present any hazard during transport, as long as the packaging remains intact.

To keep any radiation to the lowest possible level, you should stow radioactive packages:

- at the rear of the load compartment

- as far away as possible from the driver

- carefully to prevent them getting damaged during the journey

If you transport Class 7 dangerous goods (radioactive material), you should consult and may need to appoint a Radiation Protection Adviser (RPA). This can be either someone you train in-house or an external adviser.

Some loads may not be straightforward to secure using ratchet straps, for example barrels with plastic locators or palletised drinks deliveries.

You should secure loads of this type with:

- positive fit (within a box-sided or XL body)

- bungee securing sheet

- strapping over edge protectors or a pallet or similar on top of the load

Bungee sheets and edge protectors distribute the force of the securing straps and prevent damage to the load.

Glass is a high-risk load type. You should pack it and secure it carefully to prevent it falling from the vehicle.

Where possible, you should transport glass in a transport frame or within a box that can be secured to the vehicle.

It’s particularly important to secure glass carefully if you’re transporting it on a flatbed, as there will be no structure to provide secondary containment.

You can carry glass on a frail (an external frame) on the exterior of a van. The glass should not extend longitudinally more than 30cm beyond the frame in total. You should firmly attach the panes to the frail with clamps, lashing straps or rope in good condition.

You should either:

- shrink-wrap or band the kegs or barrels to a pallet to form a single unit

- use locators if you need to minimise movement

You should then secure them to the vehicle using ratchet straps or similar.

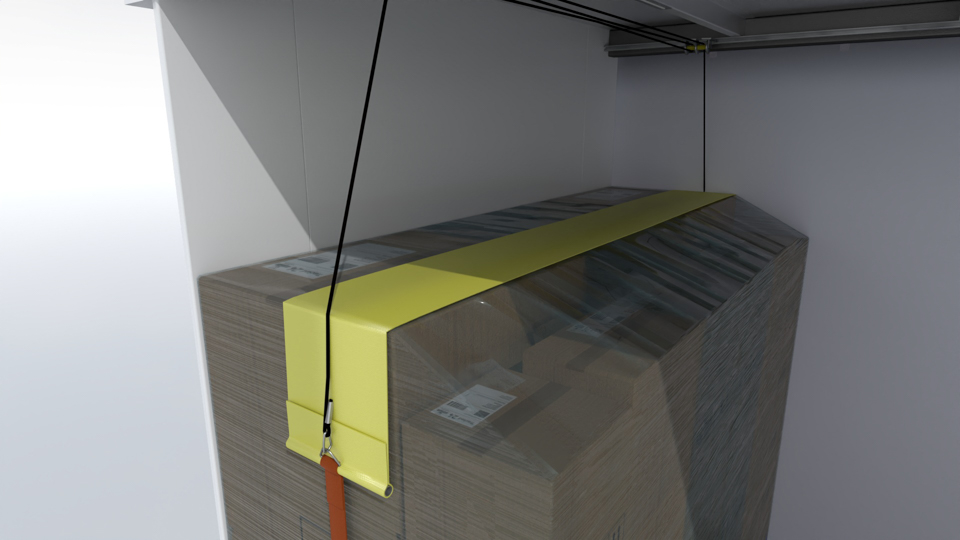

You must secure intermediate bulk containers (IBCs) with either:

- 2 lashing straps that pass over the skeleton frame

- another lashing method such as a bungee tarpaulin system that distributes the securing force across the top of the IBC

This is because the skeleton frame of an IBC does not usually have a central upright. A single ratchet strap over the IBC can deform the frame and cause the load securing system to fail.

You can use one ratchet strap over the central support if a central upright is fitted.

You can secure empty IBCs with one strap if this does not damage the frame.

Inspect the IBCs before loading to make sure they’re in good condition. Check that there are no leaks, particularly around the fittings for filling and discharging.

Preventing IBCs from moving

IBCs can slide on the load bed. You should load them against the headboard or put a physical barrier in place to stop them moving forward.

Make sure the inside face of the headboard or any other load item in front of the IBC has no projections that could pierce the container if the load moves.

Metal loads are at risk of moving due to:

- their size

- their weight

- low friction between the load and load bed

You should use a combination of lashings and physical barriers to movement to make sure that metal loads are secured correctly.

Chains are the preferred method for securing metal loads.

If you use lashing straps to secure the load, you should protect them from sharp edges to avoid the straps getting damaged or broken.

You must secure scrap metal in tipper bodies in the same way as any other load in a tipper body. You must:

- use a sheet or net if the load sits below the height of the vehicle sides – a sheet provides better containment

- use a suitable sheet or solid cover if the load sits above the height of the vehicle sides

You must not:

- rely on the load settling below the height of the sides

- use a net if the load is higher than the vehicle sides

Find out more about securing metal loads in British Steel’s load restraint guidance.

You must secure the load to the pallet to form a single unit before loading the pallet onto the vehicle. Securing the pallet to the vehicle by itself is not enough.

You can secure the load to the pallet using:

- shrink wrapping

- banding

- strapping

You can secure bulk bags and flexible intermediate bulk containers (FIBC) to pallets with:

- suitable sheets or nets

- an empty pallet or other rigid cover over the bag, secured with lashing straps

Make sure that the load cannot slide on the pallet. If the load moves on the pallet, the restraint system for that pallet and those around them could fail.

Loading pallets onto the vehicle

Check the pallets for damage or signs of weakness before loading them onto the vehicle. Do not accept them for loading if you think they are not strong enough to hold their load.

Pallets come in a variety of weights and sizes. This means that it may not always be possible to fill the load bed to achieve positive fit inside the vehicle. You can fill the gaps with packing material or use extra lashings.

When carrying pallets on vehicles with van bodies, you must restrain the pallets with lashings if there are spaces:

- between the pallets

- between the pallets and the vehicle sides

- between the pallets and the headboard

If you cannot use lashings, you must fill the spaces with packing material or dunnage to stop the pallets moving.

Load pallets as close to each other as possible along the longitudinal (front to back) centre line of the vehicle if:

- the load space is not fully utilised

- weight distribution is a concern

Stacking palletised loads

When you stack palletised loads, you should make sure that the pallets on the lower layer are strong and level enough to fully support the weight of the pallets above. Do not stack heavy pallets on top of light pallets.

Each stack must be stable without lashings when loaded.

You should use the weight of the stack rather than the weight of individual pallets when deciding on a load securing method. For example, if you stack two 300kg pallets you need to secure them as if it were a 600kg pallet.

Equipment for loading pallets

Manual handling equipment carried on the vehicle for loading and unloading, such as pump trucks, are also part of the load when the vehicle is moving. You must secure them to the load bed. Use dedicated securing points for this equipment if they’re fitted.

Take care to properly secure pallets onto vehicles that are equipped with a roller loading system.

Loading empty pallets

You should secure empty pallets like any other timber load when you carry them on flatbed and curtainsider trailers. The curtains of a standard curtainsider will not be enough to stop them moving sideways.

Lash the pallets or use another securing method, such as positive fit in an XL curtainsider.

If you stack empty pallets above the height of the headboard of a flatbed vehicle, you must create a bulkhead using at least 2 frictional lashings.

Do not stack the pallets so high that the stack is unstable and likely to fall from the vehicle. Stacks should be no higher than 4 times the longest dimension of the base of the pallet.

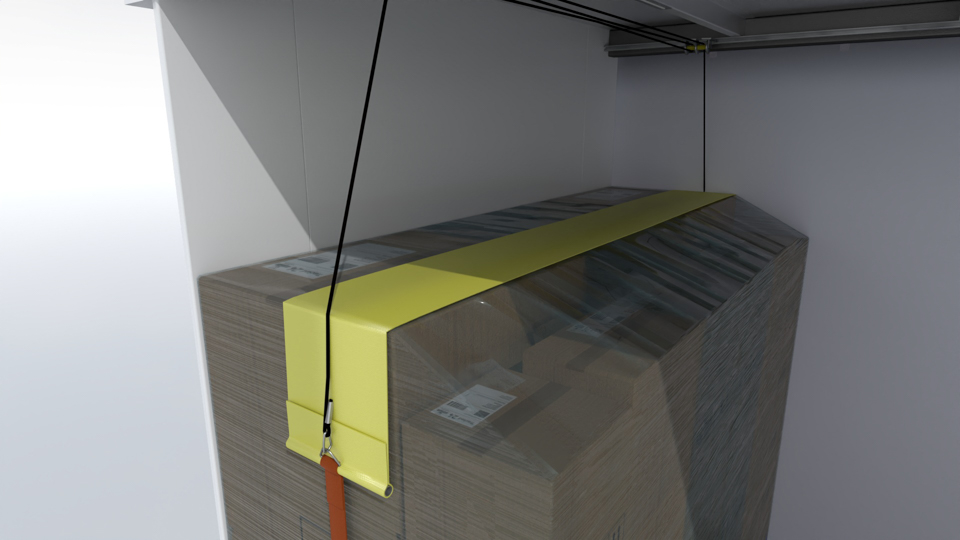

Baled paper

Only use internal buckle straps hanging from the roof rails for bales or stacks of bales that weigh up to a maximum of 400kg. Secure them by another method, like frictional lashing, if they weigh more than 400kg.

You can carry baled paper in XL-rated curtainsider trailers without additional securing if there is positive fit.

You can carry baled paper in box-sided trailers or shipping containers. Block the spaces with packing material if the bales do not fill the load space.

If the load moves around, it can increase the risk of rollover or affect vehicle handling.

Cardboard

Secure light cardboard loads (single layer items or stacks weighing up to a maximum of 400kg) in a curtainsider with buckle straps.

You can secure heavier loads with:

- positive fit

- lashing straps

- a bungee system

Paper reels

It’s important to secure paper reels correctly. They can present a significant risk of injury or death to:

- the driver

- other road users

- anyone involved in unloading

XL-bodied vehicles can provide a good level of secondary containment for paper reels. If there is no positive fit, the XL body cannot be the primary load securing system.

You can achieve positive fit by loading reels side by side within 8cm of the side curtains and 30cm from the headboard and rear doors, without gaps between each reel.

On end (vertical)

Paper reels are likely to ‘walk’ on the load bed when they’re transported on end (vertically). This can cause the restraint system to fail.

Lashings alone may not be enough to secure paper reels, and additional securing methods may be needed. This is because there is a low coefficient of friction between paper reels and the load bed.

You should use a high-friction contact surface in addition to lashings, as this will reduce the number of lashings needed.

A high-friction contact surface can be in the form of:

- the load bed flooring with a coefficient of friction greater than 0.6

- friction matting with a coefficient of friction of a minimum of 0.6

You may be able to use fewer straps if you use ratchet straps with an STF of at least 500daN.

Use additional straps on the front or rear reel or row if it is not possible to load within 30cm of the headboard or rear doors.

On reel (horizontal)

You should secure paper reels transported on reel (horizontally) with a combination of lashings and physical barriers to movement.

The barriers to movement can include:

- a well

- a cradle

- chocks underneath the reel

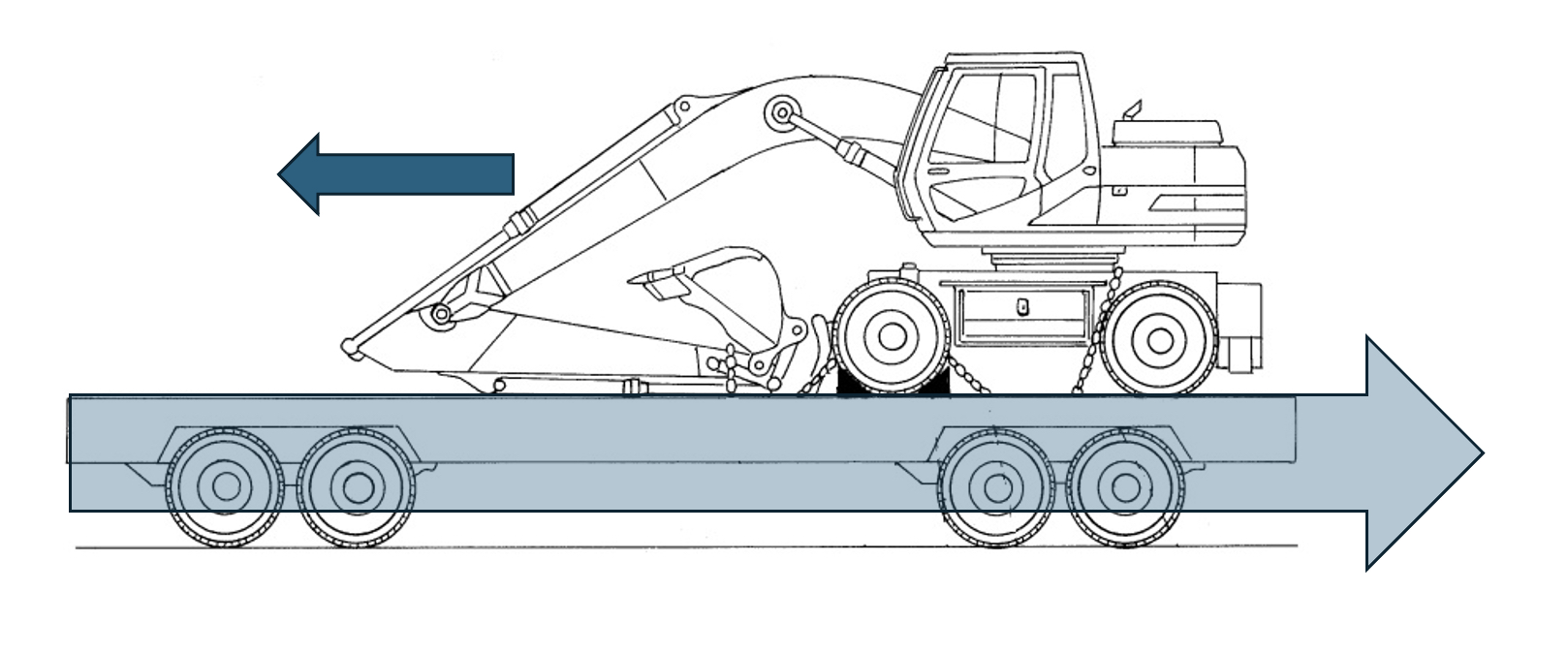

Plant equipment is usually carried on dedicated trailers that allow easy loading and securing. A lowloader trailer helps to make sure the centre of gravity is kept low to reduce the risk of rollover or other loss of control.

You should load plant to the step if you are transporting it on a lowloader. This prevents it from moving forward.

If the load bed does not adequately support the wheels or tracks of plant equipment, you should either:

- make sure the body is supported instead

- rest the equipment on timbers or something similar

Securing heavy plant

Heavy plant is defined as a vehicle not necessarily constructed for road use (such as an agricultural tractor, appliances, or construction vehicles and plant) that cannot be safely or legally transported on:

- a light goods vehicle (3,500 kg gross weight or less)

- a light trailer (maximum permitted weight of 3,500kg)

You must secure heavy plant with a combination of:

- physical barriers to the front – for example, the bulkhead or step on a low loader or step trailer

- physical barriers to the rear – for example chocks or solid timbers, which also require securing to the load bed

- lashings

The lashings for heavy plant are usually:

- at least 4 direct lashings (where one end of the lashing is attached to the carrying trailer and the other to the plant)

- frictional (tie down) lashing of any boom arms, buckets, or additional equipment

You should use a suitable securing method for the type of plant you are carrying, taking account of whether the plant is wheeled and what type of wheels it has.

When loading a vehicle with a boom arm, such as a digger or excavator, you should load it so that the arm faces away from the direction of travel. This will minimise damage from bridge strikes.

Securing light plant

You can carry light plant (such as mini excavators) on trailers. You must secure them with a combination of:

- positive fit

- frictional lashing - 3 straps or chains is enough, with one of these securing any boom arm that is operated hydraulically

Lash down loose items, like spare buckets, separately.

Precast concrete products come in a wide variety of shapes and sizes that can make them challenging to secure effectively. It is important to use a combination of physical barriers to movement and lashing to protect the driver and other road users.

You must secure precast concrete with chain or lashing straps combined with:

- loading up to the headboard or other bulkhead

- packing any gaps to the headboard with timber

- fitting stanchions or pins to contain sideways movement

You must protect lashing straps from any abrasive edges on the load and check them regularly for signs of wear and damage.

You can use:

- plastic edge protectors

- fabric protective sleeves

You must support unstable or top-heavy loads or put them in a transport frame or stillage before securing them with lashings. An unstable load can never be made safe with lashings alone.

You should load roll cages and roll containers against a bulkhead and apply the brakes if this is practicable.

You can secure the load with straps or tension bars. As a general guide, a strap or tension bar should be fitted across the width of the vehicle every 3 rows and at the very rear of the load to protect the driver and loaders during unloading.

Do not overload roll cages and roll containers. Check them regularly for damage and repair them as necessary.

Scaffolding poles and boards are likely to shift during the journey because there’s a low coefficient of friction between:

- the load and the load bed

- individual parts of the load

If the poles and boards are stacked at an angle over the headboard, you must secure them with a minimum of 2 loop (choke) lashings unless they’re individually clamped to the headboard. Frictional (tie-down) lashing is not enough to secure them.

If you stack poles and boards horizontally on the load bed, you must also secure them to the vehicle. It’s best to sheet the entire load bed (or as much of the load as possible if there are also items stacked at an angle over the headboard) and then lash the load to the bed using frictional lashings.

If there is no tailboard or the load extends behind the load bed at the rear, you must create a physical barrier to stop the load moving. This can be a temporary bulkhead or a ‘sail’. You can create a sail by wrapping a tarpaulin around the rear of the load and securing it to the load bed with straps.

You must transport fittings (connectors) in a lidded or covered container that can be secured to the load bed. A sheet may serve as the cover for the container if the load bed is sheeted.

Unloading scaffolding equipment

When loading or unloading from the rear of the vehicle at the side of the road, you should:

- park the vehicle so that it’s facing oncoming traffic

- put the hazard warning lights on

- wear a hi-vis jacket or vest – this applies to anyone involved in loading and unloading

You should only park against the traffic flow for the shortest time possible to allow safe unloading. You should not obstruct traffic or cause danger to other road users.

Single skips

You must secure single skips to the vehicle with a minimum of 2 lashings if you’re carrying them on a flatbed or lowloader.

You do not need to strap single skips to the vehicle if:

- they’re on a dedicated skip wagon

- the lifting chains are attached

- the rear hooks are in the raised position if they’re capable of providing some restraint to movement along the length of the load bed

You can use a lashing strap instead if this is not possible, as long as the skip is on a dedicated skip wagon.

Stacked empty skips

You can carry stacked empty skips on a dedicated skip wagon if:

- they’re nested

- the lifting chains are attached

- the midpoint of the uppermost skip is no higher than the height of the lifting arms in the stowed position

- the stack is secured to the vehicle with at least one lashing.

If you carry empty stacked skips on a normal flatbed vehicle, you must make sure that:

- they are suitably secured using lashing straps or chains

- any gaps between the load are minimised or blocked

- the stacks are stable and do not affect vehicle stability – this will usually mean no more than 3 skips in a stack

- skips are well seated – this will usually mean not stacking larger skips into smaller skips

Stacked loaded skips

You must not stack loaded skips or use a connecting rod or bar between the lifting arms to push down on stacked loaded skips, unless:

- you have agreed with the enforcing authorities that your vehicles have been tested to withstand the forces likely to be exerted

- you have demonstrated that you have a suitable system in place to manage the risks of transporting skips in this way

The test measures the system’s load securing capability to an equivalent technical level to the Annex B (dynamic) test set out in BS EN 12642. The vehicle is loaded in line with the test conditions, and the lifting arms and associated equipment are inspected in line with Lifting Operations and Lifting Equipment Regulations (LOLER) requirements.

Evidence of the agreed system’s suitability must be made available to enforcement bodies if they request it.

Hedge or tree trimming and roadside grass cutting activities

Carry out highway maintenance activities, like grass cutting, in a way that minimises the danger or nuisance to other road users.

You do not need to secure the load while carrying out the maintenance activity. However, you should secure the load for:

- the journey to the next location

- the journey back to the depot

Local deliveries, including brewery and coal

You do not need to re-secure the load between deliveries if you’re delivering goods to a number of premises within a small geographical area on low-speed roads (30mph or less) and using an XL rated vehicle.

However, you should secure the load:

- when it leaves the warehouse or distribution centre at the beginning of the day

- in between deliveries for longer journeys

- on the return journey to the warehouse or distribution centre at the end of the day

Employers should consider the risks to drivers when undertaking kerbside deliveries and take steps to minimise the risk of harm.

On-road activities including gritting and putting out traffic cones

You do not need to secure the load while carrying out the activity (for example, while putting out traffic cones or signs).

However, you should secure the load for:

- the journey from the depot until the point of first use

- the journey back to the depot

- longer journeys

Roadside recovery

Usually, all 4 wheels of a vehicle transported on a recovery vehicle must be secured for transport.

There are 2 exceptions to this:

-

when recovering vehicles on a fast road (50 mph or above) where you’ll be at risk securing all 4 wheels - in this case, secure 2 wheels and move the vehicle at a reduced speed to the nearest place of safety (such as the next motorway services) to secure the other wheels

-

if you’re faced with threats of violence and aggression on urban roads - in this case, secure the vehicle as well as you can and move at a low speed to the nearest place of safety to secure it fully

The journey cannot be any longer than the minimum distance required to reach a place of safety.

You must secure timber loads to the vehicle. This includes finished products.

You must secure prepared timber with lashings or chains. For long lengths of prepared timber you will usually need 3 straps rather than 2 to make sure the load does not rotate on the load bed.

You must not use rope as the primary method of securing. You can use rope to tie timber roof trusses to central goal posts for additional security during unloading.

The best method to secure uncut timber is to use chains with additional security to the side provided by “goal posts”.

Find out more about securing timber in the Timber Transport Forum’s good practice guides.

You should position vehicles being carried so that their weight is fully supported by the carrying vehicle. You can use spreader plates if you need to.

Cars and light vans up to 3,500kg on dedicated car transporters

You should complete a load plan before loading a dedicated car transporter. Having a plan will make sure that:

- drivers are safe working on and around the transporter

- the lowest loaded height is achieved

- load stability is maximised

- vehicle gross and axle weights are not exceeded

- there’s a suitable delivery drop order that does not adversely affect any of the above

Vehicles carried on specialised car transporters should face forward unless the loading scheme says otherwise or the weight of the vehicle would overload an axle.

You should distribute their weight evenly across the width of the vehicle so there’s enough space to work safely on either side. Their centre of gravity should be over the lengthwise centre line of the transporter.

Car transporters have a high centre of gravity compared to many other types of goods vehicles. Place heavier vehicles on the lower deck to reduce the risk of rollover.

You should always:

- follow the manufacturer’s recommendations when loading

- apply the vehicle’s parking brake after it has been loaded

- put the vehicle in an appropriate gear – this would be ‘park’ or first gear for a vehicle driven on to the platform, or reverse gear if it is reversed on

You can prevent the vehicles moving during the journey with a combination of:

- lashings

- chocks

The number of lashings and chocks to use depends on the load. Check the vehicle logistics safe loading code of practice for more detailed guidance on lashing strap requirements and where to place chocks.

For vehicles on a flat deck, there should be:

- 2 wheels secured by lashings (preferably diagonally opposite)

- 1 chock or lashing on a third wheel of each vehicle

For vehicles on an angled deck, there should be 3 wheels secured by either:

- 2 with lashings and 1 with chocks

- 3 with lashings

Vehicles carried at the very front and rear of a transporter must have all 4 wheels secured by lashings. This does not include the vehicle secured directly behind the cab if the transporter is fully loaded.

You should always use lashings as points of contact in preference to chocks. For example, 3 points of contact should consist of 2 lashings and 1 chock or 3 lashings. It should never consist of 2 chocks and 1 lashing, or of 3 chocks.

If it’s impractical to use chocks for some vehicles on a transporter, you can secure an extra wheel with a lashing strap. Some vehicle manufacturers recommend that each wheel should be attached.

The lashings you use to secure vehicles should be:

- manufactured to the BS EN 12195-2 standard

- rated for at least 1,500 daN

- in good condition without any obvious defects that would affect their strength

When securing the vehicles, you should:

- pass the lashings over the wheel lengthways to hold the wheel down to the load bed

- attach the lashings to dedicated attachment points or to dedicated attachment eyes fitted to the transporter or floor attachment points

- close and lock ratchets

If you use wheel chocks, they should be placed so that they secure the load against:

- the braking force on a flat deck

- gravity on an angled deck

Find out more about the rules and guidance for driving and loading a car transporter in the vehicle logistics safe loading code of practice.

Salvage vehicles

You should use 4 lashings to secure salvage vehicles. If the design of the transporting vehicle or the condition of a damaged vehicle makes it difficult to secure all the wheels, you must use either:

- lashings that pass over the top of the vehicle

- lashings that attach directly to structural parts of the chassis

- a combination of lashings that pass over the top of the vehicle or attach directly to the structural part of the chassis

You should attach the winch cable if one is fitted. However, this is not part of the securing system.

You should load damaged vehicles on the lower decks unless advised otherwise by the load plan. Use nets or a suitable cover to prevent loose items from blowing off the vehicle during transit.

Cars and light vans up to 3,500kg on other types of vehicle

Curtainsiders

The superstructure and curtains of a standard curtain-sided vehicle are not strong enough to provide load restraint for a vehicle. You must secure the loaded vehicle as if it was being transported on a flatbed.

A vehicle constructed to the BS EN 12642-XL standard may provide some containment. However, the XL body alone is not enough on its own to prevent load movement because you’re unlikely to get a positive fit.

You should think of the reinforced body structure as an extra safety measure rather than part of the load securing system.

You should:

- load the vehicle as close to the headboard as possible

- apply the vehicle’s parking brake after it has been loaded

- secure with chocks and lashings in the same way as on a flatbed trailer

- put the vehicle in an appropriate gear

Flatbed trailers

Flatbed trailers do not have a superstructure to stop a load moving, so you need to use additional securing methods.

You should:

- load the vehicle as close to the headboard as possible

- apply the vehicle’s parking brake after it has been loaded

- secure all 4 wheels with lashings or wheel tethers

- put the vehicle in an appropriate gear

Recovery transporter trailers

You should attach the winch cable if one is fitted. However, this is not part of the securing system.

You must secure all 4 wheels.

If the design of the transporting vehicle or the condition of a recovered vehicle makes it difficult to secure the wheels, you must use either:

- lashings that pass over the top of the vehicle

- lashings that attach directly to structural parts of the chassis

- a combination of lashings that pass over the top of the vehicle or lashings that attach directly to the structural parts of the chassis

You should use nets or a suitable cover to prevent loose items from blowing off the trailer during transit.

Stacked vehicles

You should stabilise stacked vehicles with stanchions or pins before securing them with lashings.

Use webbing sleeves to protect any lashing straps that pass over the stack.

If more than one vehicle is carried by piggy-back, you must:

- lash each vehicle to the one below

- lash the entire load to the transporting vehicle

Lashings used to secure vehicles should be:

- manufactured to the BS EN 12195-2 standard

- rated for a lashing capacity of at least 1,500 daN

- in good condition without obvious defects that would affect their strength

Vehicles over 3,500kg on car transporters

There should be 4 points of contact between the vehicle and the transporter, consisting of either:

- 2 chocks and 2 lashing straps - preferably on diagonally opposing wheels

- 1 chock and 3 lashing straps

- 4 lashing straps (one on each wheel)

Vehicles over 3,500kg on flatbed trailers

Ideally, you should move vehicles over 3,500kg on lowloader trailers so that the centre of gravity is as low as possible. A high centre of gravity can affect the stability of the transporting vehicle and increase the risk of rollover or loss of control.

You should:

- load the vehicle as close to the headboard as possible

- apply the vehicle’s parking brake after it has been loaded

- put the vehicle in an appropriate gear

There must be 4 points of contact between the vehicle and the trailer, including:

- lashing straps on each wheel

- at least 2 chocks or other physical barrier to movement

You may need to secure damaged vehicles with:

- chains

- direct lashings

- lashings attached to structural parts of the chassis

Heavy goods vehicles

You should move tractor units and trailers on low loaders so that the centre of gravity is as low as possible. A high centre of gravity can affect the stability of the transporting vehicle and increase the risk of rollover or loss of control.

You should:

- apply the vehicle’s parking brake after it has been loaded

- chock the wheels or place the vehicle up against the swan neck or other bulkhead to stop it moving

- secure the vehicle with direct lashing

- put the vehicle in an appropriate gear

Use a minimum of 4 lashings, secured as part of 2 opposing pairs. The angle of the straps or chains relative to the load bed should be as close to horizontal as possible. You can use additional frictional lashing (up and over the load) using lashing straps to increase the safety of the load.

Use the vehicle’s attachment points if it has them. You should also attach lashings to rated attachment points on the lowloader or flatbed load bed wherever possible.

Do not attach lashings to sheeting hooks, as these are not strong enough.

Carrying trailers by piggy-back

If you’re carrying more than one trailer by piggy-back, you must:

- lash each vehicle or trailer to the one below with at least 4 lashings

- secure an additional 4 tie-down lashings over the entire load

You should consider the effect on vehicle stability and overall height when deciding how many trailers to transport like this.

Motorcycles and scooters

You should use a dedicated motorcycle trailer to transport motorcycles if possible.

If you do not use a dedicated motorcycle trailer, motorcycles can be either:

- transported in a box or cage that can be strapped down to the load bed

- chocked or placed in a frame and lashed to the vehicle

If you’re transporting scrap bikes you can lay them down and lash them to the load bed.

You can secure work cabins and containers on flatbed vehicles using:

- twistlocks (if available)

- lashings

If you do not use twistlocks, you should:

- load the cabin or container as close to the headboard as possible

- pack the gap between the headboard and cabin or container with timbers or empty pallets if the gap is more than 30cm

You should use a high friction surface between the cabin and the load bed.

Secure the cabin or container to the load bed by either:

- a minimum of 3 frictional lashings

- 4 direct lashings attached to separate lashing points

Damaged twistlocks

The twistlocks or twistlock sockets on containers or cabins can become damaged. When this happens, you may not be able to lock the load to the carrying vehicle at the damaged corner.

If this happens, you should not use the damaged socket as an anchor point.

You must:

- secure the undamaged corners with twistlocks

- use a minimum of 2 lashing straps to secure the load by frictional (tie-down) lashing