DASA funded innovation gives old body armour a second life

Veteran-run, green tech start-up has developed innovative technology to recycle the materials in body armour with the help of DASA funding

- With the help of DASA funding, Uplift360 has created an eco-friendly, low-energy method of recycling fibres that are used in body armour.

- Their innovation uses sustainable chemicals to turn waste para-aramid fibres into a liquid, this liquid can be spun back into a high performance material, with very similar characteristics to virgin material. Through this recycling process, high value materials can be put back into the supply chain.

- By following circular materials practices and utilising low-energy recycling technologies, this breakthrough could lead to a reduction in Co2 emissions, strengthen vulnerable supply chains, and provide substantial cost savings for Defence by preserving valuable and expensive body armour materials.

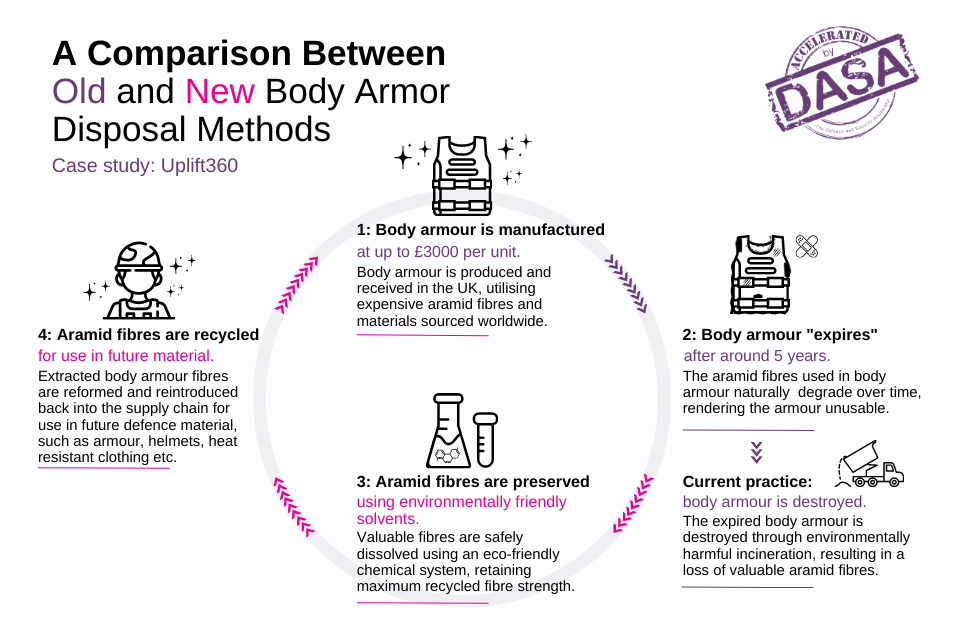

Body armour is a vital capability used to save lives and protect soldiers on the battlefield, designed to reduce the impact of small arms fire and blast fragmentation. However, body armour has a shelf life of around 5 years, because of the natural breakdown of para-aramid fibres (commercial names include Kevlar®, Twaron®, etc) that are used in body armour manufacturing.

Currently, when body armour expires, it is incinerated, resulting in the loss of valuable para-aramid fibres, estimated to be 85 times more expensive than steel. Para-aramid fibres are also found in other parts of defence, including airplanes, land vehicles, uniforms, and helmets.

The MoD released its Climate Change and Sustainability Strategy in March 2021, which noted a requirement to build circular economy principles into defence, by minimising wastefulness and considering the disposal and environmental impact of materials. Due to the high cost of manufacturing body armour (with each unit costing up to £3000), there is a clear need for more effective material preservation practices. The Defence Supply Chain Strategy released in 2022 also recognised the need to secure critical supply chains as part of defence support.

Introducing Uplift360: Circular economic practices for body armour material

Veteran-run, green-tech start up, Uplift360, recognised the opportunity to improve the methods used to dispose body armour. They have devised a method that allows para-aramid fibres to be recycled while preserving their original strength, enabling their reuse in defence materials with the potential for dual and multi-use application across sectors.

Funded through the DASA Open Call in 2021, 2022 and 2023, the innovation uses environmentally friendly, recyclable solvents to dissolve para-aramids into a concentrated solution so they can be reformed into like-new fibres. The system utilises a wet-spinning approach, where the aramid material is passed through a syringe into a bath of the eco-friendly solvents, and a rotating device is used to “re-spin” the fibres back to structural uniformity.

DASA funded innovation gives old body armour a second life

This represents a breakthrough in the potential longevity of body armour materials. The inherent strength and chemical resistance of para-aramids have previously meant that they could only be disposed of through chopping into small fragments which have few uses and little value, or environmentally damaging methods, such as high temperature incineration.

Not only have Uplift360 found a solution to recycle aramid-fibres in environmentally friendly way, but also the capability to retain its strength so it can potentially be used create new body armour or be used in other critical applications.

Minster of State for Defence, Baroness Goldie said:

The process designed by Uplift360 is a really good example of how new and intelligent thinking can transform old practices in Defence. Their innovative approach could reduce wastage, save money and secure supply without compromising on high quality kit for our armed forces. I look forward to seeing their important work continue to help Defence make even more progress toward reducing emissions.

Another key advantage of Uplift360’s innovative recycling system is that the fibres remain highly versatile for reuse after recycling and have the potential to be reintroduced back into the supply chain, in materials across defence, civilian and humanitarian purposes. For example:

- flame and heat resistance clothing

- stab/cut resistant clothing

- ropes

- civilian clothing such as hiking gear

- airframes

- tyres

- backpacks

- gloves

- fibre optics

With recent events, such as Covid-19 and the Ukraine conflict demonstrating how fragile supply chains can be, using circular economic practices to regenerate body armour material will not only help Defence reduce costs, but also help support more resilient supply chains.

Uplift360’s journey with DASA

Founded in 2021 by a veteran and military spouse, Uplift360 has already made significant strides in promoting circular economics in defence, leveraging their defence backgrounds and expertise to drive sustainability forward. After initially exploring textile sustainability with DASA, they shifted their focus to more eco-friendly body armour. Despite being a new player in the market, Uplift360 has achieved remarkable success in a short span of time, receiving £495,577 in project funding from DASA.

Jamie Meighan, Uplift360 Chief Executive Officer and Co-Founder

DASA has been instrumental to the success of Uplift360. From a concept to our initial investment to creating our ground-breaking technology in our labs, DASA has been there every step of the way. As a Veteran/Spouse start up is was very important from the outset to find funding, mentors and support that understood us as a business, saw the potential of our technology and believed in it. Supporting Uplift360 clearly shows DASA’s commitment to help achieve a more sustainable future, maintain resiliency and save money for Defence.

DASA funding served as a critical stepping stone in their journey. The funding was not only valuable to develop the technology from concept to working prototype, but also served to demonstrate the innovative nature of the technology while signalling government support for its development.

Uplift360 has gone on to successfully raise Angel and venture capital funding, and they were also selected to evaluate the potential for a circular economic approach in the development of a future net zero aircraft, as part of the RAF’s Rapid Capabilities Office MONET Project award. Their sustainability efforts have also earned the support of the Luxembourg government, which has provided funding for complimentary work on a separate project.

Currently a team of 5 which is growing, the future is bright for Uplift360, with numerous successful funding rounds and interest from international allies. With their most recent round of DASA funding, their next step is to work with aramid manufacturers to further demonstrate the technology at wider scale. Uplift360 have also just secured their initial seed investment. Into the future, they are also exploring the potential of applying their innovative technologies to carbon fibre composites, a critical component in many military materials and capabilities.