Flush to Fuel; transforming wastewater into hydrogen power

Wastewater Fuels have developed an innovative solution to turn sewage into sustainable hydrogen energy

- With the help of DASA funding, Wastewater Fuels have developed a unique innovation to harness energy from wastewater

- The system uses stainless steel mesh rods in wastewater to break down organic material into hydrogen ions which are converted into hydrogen gas and stored in the rods

- Proven through several trials, Wastewater Fuels is preparing for the production of a full-scale sewage facility to be deployed at RAF Digby

Every day, people create potential fuel through waste, so why aren’t we harnessing it? This is the question that Warwickshire based SME, Wastewater Fuels has set out to solve – with the help of DASA.

From drains to gains: Importance of treating waste water

Treating wastewater is crucial for protecting the environment and ensuring the health of both humans and animals. Inadequately treated wastewater has the potential to pollute water sources, damage ecosystems, and cause serious illnesses. Despite this, 80% of wastewater produced globally goes untreated. Traditional wastewater treatment methods, like mechanical filtration or physical sedimentation, are efficient but can be energy-intensive or costly to implement, particularly in remote or challenging environments.

In the UK alone, about 2-3% of National Grid energy is dedicated to treating wastewater. This requires 9,000 water treatment sites across the country and represents a significant amount of energy used to treat sewage.

If a method existed to treat wastewater and simultaneously utilise it as a fuel source, it could have transformative potential as a new energy source. This new approach could lead to wastewater treatment producing more energy than it consumes.

Introducing Wastewater Fuels: innovative ways to save energy in sewage works

Warwickshire-based SME, Wastewater Fuels, have developed a unique innovation to harness energy from wastewater - utilising environmentally friendly practices and circular economic systems that capture hydrogen energy.

The organisation first submitted their idea to the DASA Open Call in 2021 – called a Microbial Electrolysis Cell (MEC). It works by submerging numerous stainless steel mesh rods in wastewater, which is then treated by microbes that consume organic wastewater matter. This consumed matter is transformed into hydrogen ions, which are further converted into hydrogen gas and stored within the rod.

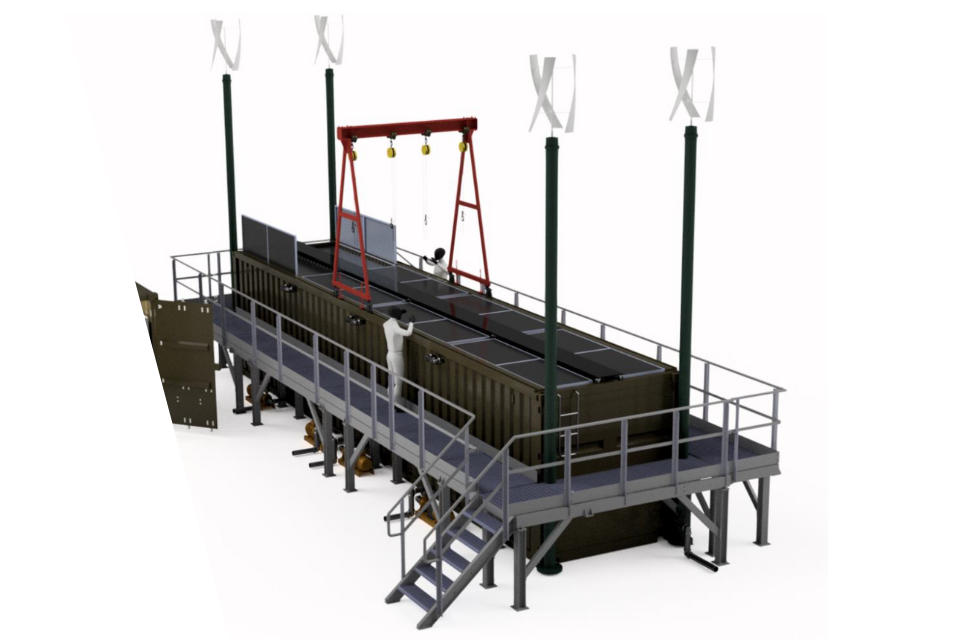

Example of Wastewater MECs

In simpler terms, the setup functions as a filter that allows wastewater to pass through. The outer material is electrically conductive and encourages the growth of microbes. These microbes break down the organic matter in the water, leading to the production of hydrogen which is then collected.

How do Microbial Electrolysis Cells work?

- A rod assembly is immersed in wastewater.

- Friendly microbes colonise the outside of the rod.

- Organic matter consumed by microbes is converted into hydrogen ions.

- Hydrogen ions diffuse into the core of the rod.

- Within the core, the ions are converted into hydrogen gas.

- The gas collects in the manifold above the rod, ready for use.

Circular economy and benefits for defence

Not only does this technology support the UK Government’s commitment to achieving NetZero Green House Gas emissions by 2050 and ‘slashing’ emissions by 78% by 2035, it also supports the Ministry of Defence’s desire to incorporate more circular economy principles into defence operations.

Wastewater Fuel’s innovative setup demands less space, maintenance and equipment in comparison to current wastewater treatment assets. The MECs involves no moving parts, meaning less wear and tear, reduced component replacement, and easier maintenance. This makes them an ideal choice for deployment in locations with urgent water treatment needs, like austere and frontline environments, or where circular energy is essential.

Lt Col Simon Watkins RLC, SO1 Research & Experimentation

The capability has the potential to increase self-sufficiency and reduce water treatment costs across the Defence Estate. With enormous potential for Defence, the Futures team feels privileged to have sponsored the development of a deployable prototype.

Key advantages for Defence:

- Purifying the waste stream that contains organic material.

- Dramatically reducing the energy required to process wastewater

- Removing contamination as it passes through the MEC reactor while converting the waste into hydrogen energy.

- Minimal moving parts and low maintenance.

- Individual rods in a treatment system can be repaired and replaced as needed meaning that the system doesn’t need to be taken out of service for repairs.

- The stored energy can be used on-site, stored, compressed, distributed, or even utilised in vehicles.

- It can also be used for numerous civilian applications apart from wastewater treatment, such as food waste, farm organic waste and industrial brewing waste.

Example of water treatment facility equipped MECs

Pipeline to progress

Wastewater Fuels has had a rapid and impressive start in the last few years. Initially established by Daniel Carlotta-Jones (Chief Engineer), Martyn Lathbury (CEO) and James Stratford (CTO) and initially operating from a garage, the organisation has grown rapidly, now supporting a team of 18 employees and showing continuous expansion.

The team encountered various obstacles during the system development phase, such as ensuring the MECs were capable of capturing hydrogen instead of leaking. Leveraging DASA’s adaptable work approach, centred on innovation and flexibility, Wastewater Fuels managed to overcome these challenges, further enhancing and refining the system with increasing sophistication over time.

Martyn Lathbury, CEO, Wastewater Fuels explained:

Funding via DASA enabled us to start developing MEC’s and resolve the numerous challenges that had to be solved to achieve effectiveness at scale. This has allowed us to demonstrate capability, gain further investment, grow the business and foster close engagement with MOD StratCom to understand their requirements and trial the system at full scale.

Wastewater Fuels is collaborating with Severn Trent Water, who have provided access to different sections of their wastewater treatment facilities at Spernal to trial the innovative water treatment assets. Initial successful tests indicate that Wastewater Fuels’ MEC wastewater plant will be self-powering with substantial hydrogen generation capability for compression, storage and distribution and/or generating electricity by feeding the hydrogen into fuel cells.

Coventry City Council has further backed the initiative by providing additional funding. This backing has enabled Wastewater Fuels to maintain their headquarters in Coventry, close to their local suppliers, reducing supply chain expenses and fostering better collaboration. This approach has helped improve the production of their innovative MEC rods, in preparation for the production of a full-scale sewage facility to be deployed at RAF Digby, at the current wastewater facility, managed by Severn Trent Services and in collaboration with Defence Support (Def SP) Futures R&E and jHub.