5. How to load different HGVs, light goods vehicles, small vans and cars

How to secure loads on different types of vehicle.

You must secure agricultural loads in the same way as any other load when travelling on a public road, even if the journey is short and the vehicle is travelling at low speed.

Box pushers

A box pusher uses a hydraulic press to force a box or load towards the headboard or bulkhead of a vehicle.

In order to stop the load from moving during transit, you should:

- check that the box or container, the headboard and the box pusher are in good working order

- keep the journey relatively short (for example, from the field to a storage place)

You should not:

- double or triple-stack the boxes vertically

- exceed the speed limits for agricultural vehicles

Use extra securing methods (like over-the-top lashings) if any of these conditions are not possible.

Bulk tippers

You can use bulk tippers to carry a variety of loose loads, including:

- sand

- soil

- aggregate

- construction waste

- scrap metal

- sugar beet or other crops

- silage and agricultural material

The body of the tipper will prevent the load moving forwards, backwards, and to the side.

Covering the load will prevent it from bouncing out of the vehicle when you take it on the road.

In some circumstances, where the load sits below the sides of the vehicle, you might not need to use an appropriate cover. The operator must assess the risks and be able to justify it as a safe system.

If your risk assessment shows you need an appropriate cover

You must:

- use a sheet or net if the load sits below the height of the vehicle sides – a sheet provides better containment

- use a sheet if the load sits above the height of the vehicle sides – it must completely cover the load bed with no gaps to any side

- use a suitable sheet or a solid cover if you’re transporting divisible loads like aggregate or scrap metal items that are higher than the vehicle’s sides

You must not:

- rely on the load settling below the height of the sides

- use a net if the load is higher than the vehicle sides

Flatbeds and lowloaders

You can use flatbeds and lowloaders to transport many different load types.

They have no body structure (sometimes not even a headboard), so they offer flexibility in loading and unloading.

However, this also means:

- it can be difficult to secure some heavy load types, such as some steel loads

- the load will not be contained if the securing system fails

You must load against the headboard or within 30cm of it wherever possible. If this is not possible for weight distribution reasons, you can:

- use blocks, timbers, dunnage, or chocks to prevent items moving forward – make sure that they’re properly secured to the vehicle platform

- use additional lashings to prevent forward movement

- fit an obstacle, such as stacked timber secured by lashing, across the load bed and attach it firmly to the vehicle – this effectively moves the headboard towards the back

You should reverse plant equipment onto the trailer if possible and place it against the step, for example on a low loader, to stop it moving forward. The wheels or tracks must be sufficiently supported by the load bed. If this is not possible, the body of the equipment must be supported instead.

Vehicles carried on flatbed vehicles and trailers such as car transporters and recovery trailers must be restrained for transport. You should attach the winch cable if one is fitted. However, this is not part of the securing system.

Drop and fixed sided flatbeds

You cannot rely on the sides of drop or fixed sided flatbeds to secure a load by themselves. In some circumstances, load items could bounce over the sides.

You must:

- secure individual items using lashings wherever possible

- cover the load bed with a net or sheeting

- place items against the headboard or within 30cm of it wherever possible

- attach any lashings you’re using to the vehicle chassis before fixing the vehicle sides

Most of these vehicles have a gate-type sided system. The sides are secured by being locked to anchor stanchions fitted to the bed of the vehicle. These must be kept in good condition. You must repair any defects as soon as possible.

You must make sure that the load cannot move backwards if the vehicle has sides but not a rear bulkhead. You can do this by using:

- additional lashing

- another method such as a rear tarpaulin secured by lashing

Unloading from the rear of a drop or fixed sided flatbed

When unloading from the rear of the vehicle at the side of the road, you should:

- park so the vehicle is facing oncoming traffic

- put the vehicle hazard warning lights on

- wear a hi-vis jacket or vest - this applies to anyone involved in loading and unloading

You should only park against the traffic flow for the shortest time possible to allow safe unloading. You should not obstruct traffic or cause danger to other road users.

Standard curtainsiders (Tautliners)

Standard curtainsiders are designed to keep the load out of sight and protect it from the weather. The superstructure is not designed to be load securing.

You can only use anything attached to it (such as buckle straps or internal nets hanging from roof rails) to secure loads up to a maximum of 400kg.

XL curtainsiders

Vehicles built to the BS EN 12642 XL standard can withstand a minimum of 40% of the rated payload to the side without additional load securing if they’re loaded to the manufacturer’s specification.

However, for proactive enforcement purposes, XL vehicles are accepted as restraining 50% of the rated payload to the side without any extra securing if the load fills the entire load area:

- within 30cm of the front

- within 30cm of the rear

- within 8cm of either side

- without cumulative gaps or a single gap of more than 30cm along the vehicle load bed

This is often referred to as ‘positive fit’.

The BS EN 12642 XL standard

BS EN 12642 is a build standard for the entire vehicle. It applies to the whole vehicle structure, including the:

- curtains

- doors

- headboard

The strength of the vehicle body must be verified by the manufacturer and the vehicle should be clearly marked as an XL body. It must be supplied with a certificate or other documentation to confirm that the body is rated for load securing. The curtains of an XL body must also be manufactured to BS EN 12641.

When the standard is not met

Fitting XL rated curtains to a standard or ‘L’ rated vehicles does not meet the standard. You would need additional load security even if the load meets the positive fit requirements.

The XL rating is not effective if:

- the front of the load is more than 30cm away from the headboard

- the rear of the load is more than 30cm away from the rear doors

- there is a gap between the load of more than 30cm along the length of the load bed

- there are significant gaps along the length of the load that are cumulatively more than 30cm

- there is a gap, to the side, between the load and the vehicle/trailer side of more than 8cm

Diminishing or part loads

You can fit lateral bulkheads or use packing material to fill gaps in the load to guarantee positive fit.

You can transport diminishing or part loads in an XL vehicle as long as:

- any gaps created by a diminishing load are blocked to maintain positive fit

- a partial load which does not fill the load area has extra securing

For example, lashing straps across the rear of the load must provide security for 50% of the entire load. This will secure the load in the same way as the rear of the vehicle would for a full load. Or, the load can be secured as it would in a non-XL rated vehicle.

Chipliners

Chipliners are a special type of curtainsider used to transport forest bulk products. They have more buckles in the curtains than a standard curtainsider.

They do not usually require additional securing.

Make sure that they’re well-maintained and repair any damage to the curtains, including to the buckles, as soon as possible.

Loads other than forest bulk products transported in a chipliner, including waste, must be secured as if they were being transported on a standard curtainsider.

Tilts and Euroliners

Euroliner semi-trailers have an internal frame running down their length, usually hidden by standard curtain sides. Different sized beams (made of aluminium or wood) can be placed in the frame. These can be:

- lengthways – this strengthens the side

- across the width of the vehicle – this separates the load

Tilt trailers also have an internal frame, but they do not have the same structure as a standard curtainsided trailer. UK-based vehicle operators do not usually use them.

Light palletised goods (where each item or stack of items weighs up to a maximum of 400kg) can be transported inside a Euroliner or tilt without additional securing as long as:

- the load bed is filled to prevent the contents from moving when in transit (positive fit)

- the load is stacked against the headboard, or with any gap between the front of the load and the headboard packed to prevent it sliding forward

- the gap between the sides of the load and the frame or beams is less than 8cm

- additional measures are in place to stop rearward movement if the load does not reach the rear doors or within 30cm of them

- the beams and frame are in a usable condition – there are no cracks or obvious signs of damage, decay, or rot

- the beams contain the load so that there is no risk of items falling from the trailer when the curtains are pulled back – the load cannot escape under, through or over the beams

Additional securing will be needed if:

- the vehicle is used to carry palletised or stacked loads which weigh over 400kg

- the goods do not fill the load area (positive fit)

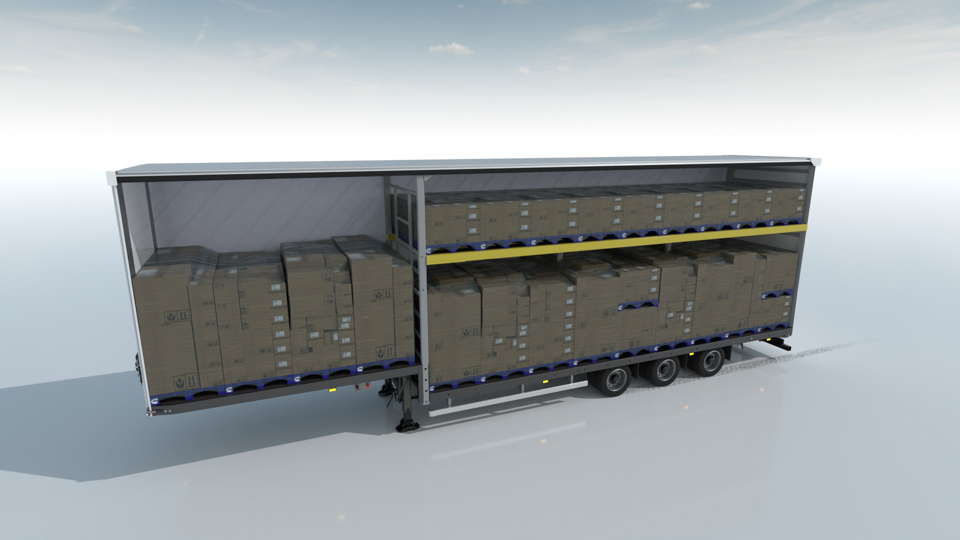

Multi-deck trailers

Multi-deck trailers have three deck areas:

- the main deck

- the swan neck

- the upper (or lift) deck

There are specific risks to using multi-deck trailers because of the height of the upper deck. When loading a multi-deck trailer, you need to consider the risks of working at height on the upper deck and load items falling from the upper deck.

Items, boxes, or palletised goods carried on the upper deck must:

- be loaded in a single layer – do not stack them

- be stable without lashings

- weigh up to a maximum of 400kg

You must secure palletised goods to the pallet and to each other before loading and securing them on the trailer.

Use a ground-operated internal net or securing system to protect drivers and site personnel from items falling from the upper deck when the curtain is pulled back for unloading.

Internal nets or roof-mounted buckle straps must not be used for items or stacks weighing over 400kg. You must load heavier items and stacks on the main deck or swan neck and secure them as you would on a single-deck trailer.

You should take the same precautions against items falling from the upper deck for trailers constructed to the BS EN 12642 XL standard, even if the trailer body structure is sufficient to provide on-road load securing. You may want to use additional securing methods if the load does not fill the entire upper deck (positive fit).

Boxsiders

You can use box-sided vehicles (sometimes called rigid-sided vehicles) to transport a wide variety of goods.

The rigid sides are usually enough to prevent the load moving sideways. However, unsecured loads can:

- increase the risk of rollover

- affect vehicle handling, including braking performance

Loading box-sided vehicles

To prevent the load moving during transit, the load must be:

- against or within 30cm of the headboard

- without cumulative gaps or a single gap of more than 30cm along the vehicle load bed

- within 30cm of the rear doors

If there are gaps larger than 30cm between the back of the load and the rear doors you can:

- fill the space with empty pallets or packing material

- use straps or bars behind the load

Loads that can affect a box-sided vehicle’s stability

The rigid sides of this type of vehicle mean you can secure pallets over 400kg on both the lower and upper decks of multi-deck vehicles. However, you should load heavier pallets on the bottom deck to help keep your vehicle as stable as possible.

The movement of hanging or live loads (such as animal carcasses hanging from rails) can create a pendulum effect. This can affect your vehicle’s stability.

You should include the risk presented by different loads in your risk assessment and take appropriate steps to manage any risk.

Unloading box-sided vehicles

You should consider how to unload safely without the flexibility that flatbed or curtainsider bodies allow. This is particularly important where drivers are making kerbside deliveries using a body-mounted tail lift, as there is a risk of the load or the driver falling from height.

Cars

Loads carried in passenger cars must be loaded and secured so there is no risk of harm to:

- the driver

- passengers

- other road users

This applies whether you’re driving for work or leisure.

Wherever possible, you should place loads in the boot of the car, against the bulkhead. Fill any gaps so the load cannot slide around.

Always load hazardous, sharp, or heavy items in the boot if possible.

Roof racks

Do not put loads heavier than the manufacturer’s recommended maximum weight limit on roof racks.

You must secure the load to the roof rack with:

- cargo ratchet straps

- effective clamping

Effective clamping is generally provided by specific products used to secure loads, such as bike roof bars.

Do not use rope, bungee cords or other cords or cables. They will not secure the load effectively.

You should tie down any loads that project significantly in front of the support of the roof rack, like ladders and canoes. Use strong rope to tie them to the front of the vehicle.

You must never load items directly onto the roof of a car, because:

- it is not designed for this purpose

- friction between the roof and the load is likely to be very low

- there will not be enough suitable attachment points to secure the load properly

Refrigerated vehicles (reefers)

Refrigerated vehicles have rigid sides that are usually enough to prevent the load moving sideways. However, unsecured loads can still increase the risk of rollover or affect vehicle handling, including braking performance. You can use cargo bars or restraint poles to reduce load movement.

Ice can build up in the vehicle, which could reduce the coefficient of friction between the goods and the load bed.

Vans

This section applies to any type of van (from small car derived vans up to larger box vans) used by tradespeople, couriers, or for delivering goods of any kind.

The rigid sides of a box van will usually be enough to prevent the load moving sideways. However, unsecured loads can still increase the risk of rollover or affect vehicle handling, including braking performance.

Where possible, you should:

- load items against a bulkhead

- group smaller items together within a box or container

- secure large or heavy items to the vehicle

- use positive fit

There must be a bulkhead between the load compartment and the cab to protect the driver and any passengers from load movement under heavy braking. This should be in a usable condition and strong enough to stop whatever is in the load compartment coming forward. It should not have any gaps in it that could allow a load item into the cab.

If the vehicle has been converted from a van body and is now classed as a motor caravan (motor home) by DVLA, it does not need a bulkhead between the cab and the rear of the vehicle. However, you should make sure that items in the rear are safely stowed for the journey.

If you’re carrying out multi-drop deliveries, check that the load is still in a safe condition between drops to minimise any movement that might affect vehicle handling.

You must not store load items, including work tools and gas cylinders, in the cab.

Roof racks

If you load ladders or other work equipment on a roof rack, you must:

- not exceed the manufacturer’s recommended weight limit

- clamp the load or secure it to the roof rack with cargo ratchet straps

You must not use rope as the main method of securing. However, you can use it to tie down the front of a long load to stop it lifting off the roof rack once the vehicle is moving.